- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

Contact Information

University: Georgia Institute of Technology

Team Members (with year of graduation):

- Martin Ertlschweiger (Dec. 2012 / zwcoolkid@gmail.com)

- Matt McCurley (Dec. 2012 / mmccurley@gatech.edu)

- Vijai Narayanan (Dec. 2012 / vijai747@gmail.com)

- Ted Turner (Dec. 2012 / tturner787@gmail.com)

- Taylor Williams (Dec. 2012 / twilliams06@gatech.edu)

- Enrique Zaldivar (Dec. 2012 / quicoz90@gmail.com)

Faculty Advisers: Harvey Lipkin (harvey.lipkin@me.gatech.edu)

Email Address: (see above)

Submission Language: English

Project Information

Title: TrackVIEW -- Intelligent Starting Block for Sprinters

Description:

The TrackVIEW system is designed to improve a sprinter's start off the block by analyzing his or her posture and gait during the first three steps of a trial. It does so by processing data from a combination of sensors (accelerometers, strain gages, etc.) installed in the starting block and a video camera set approximately 15 feet away from the runner.

Products:

NI cDAQ-9174 4-slot USB chassis

NI 9235 8-channel quarter bridge strain gage module

NI 9234 4-channel accelerometer module

NI 780985-01 industrial accelerometer

NI LabVIEW 2013

NI Vision Builder for Automated Inspection

Logitech HD Pro C920

Cannon 8' adjustable tripod

OMEGA KFG-3-120-CL-11L1M2R strain gages

The Challenge:

The current state-of-the-art in the field of sprinting at the high school and college levels is surprisingly low-tech. Many coaches still use manual data collection methods to take measurements such as reaction time and stride length. Providing additional data about a runner's performance would allow coaches to give better feedback to runners about their posture and gait, thereby improving a runner's performance significantly over the course of a track season. TrackVIEW aims to bring both sophisticated data collection and automated analysis to this market using NI hardware and software. Using data collected by sensors and video footage, the system provides coaches with important metrics such as reaction time, force off the block, stride length, back angle, foot position over time and heel height.

The Solution:

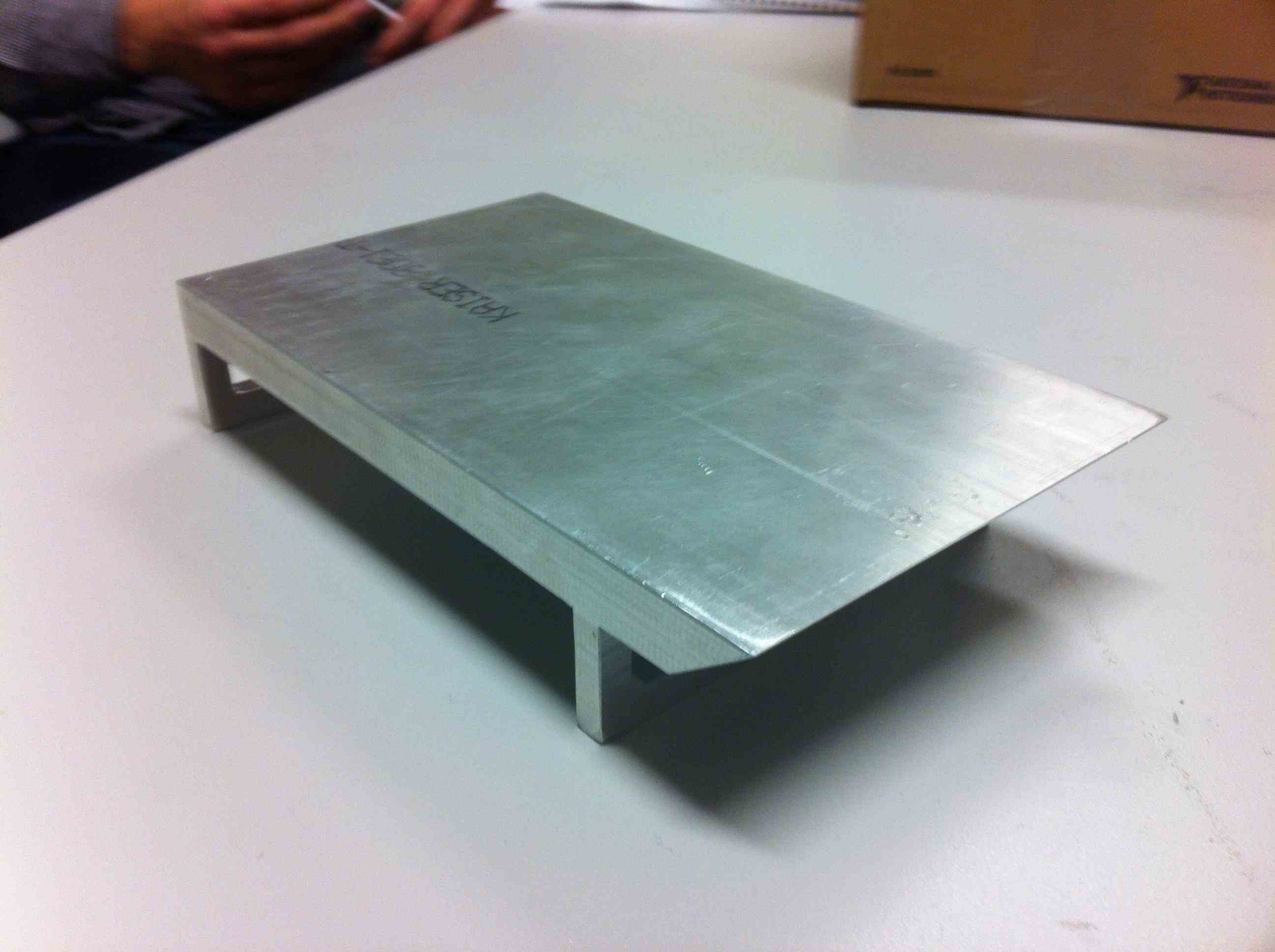

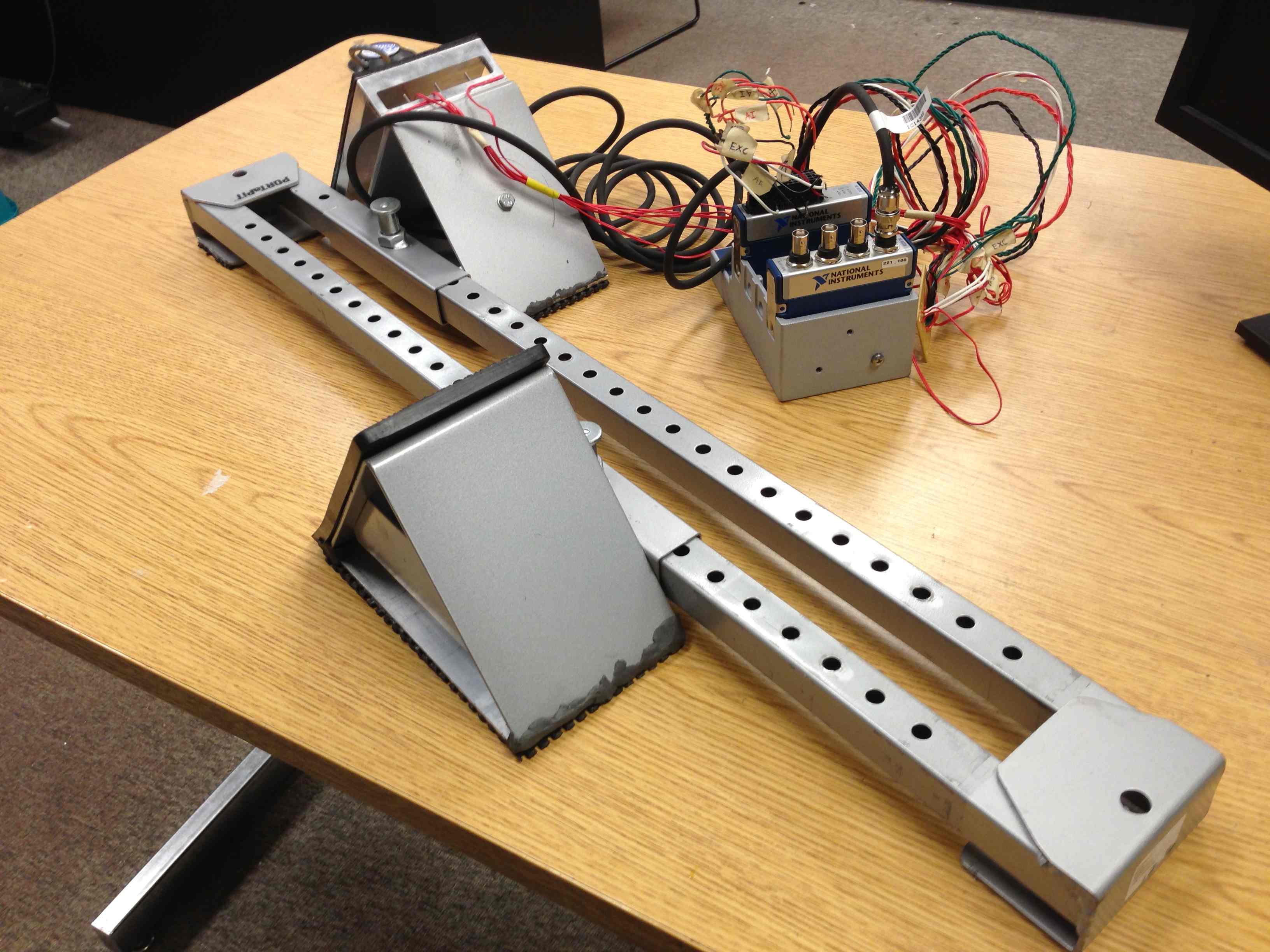

TrackVIEW consists of two subsystems -- the starting block and the webcam. The starting block is mounted with a custom aluminium footpad (see Fig. 1) and accelerometer. A set of four strain gages are attached to each corner of the footpad using epoxy, and the accelerometer is screwed directly into the block. An NI cDAQ is used to gather data from both the strain gages and accelerometer (see Fig. 2). A LabVIEW VI produces a "starting noise" and collects data from the system. A calibration factor is used to resolve the strain gage measurements into a force on the block, and the accelerometer is programmed to ignore the runner's adjustments on the block and record his or her true reaction time (see Video 1).

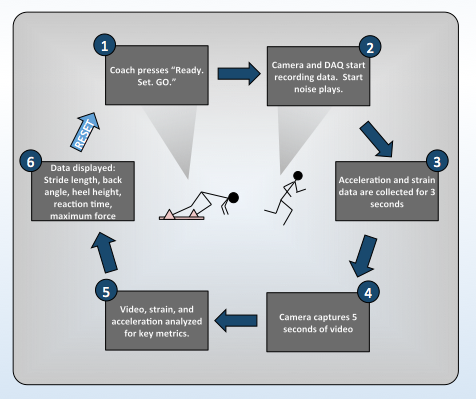

The webcam is mounted on a tripod and placed approximately 15 feet from the starting block. This distance was determined to be appropriate to capture the first three steps of a sprinter's trial, which are said to be the most crucial in a short distance race. The LabVIEW VI is written to both record and analyze the video. To record the video from the webcam, the VI uses the IMAQdx package of drivers and LabVIEW blocks. The video analysis is accomplished using a VBAI script, which tracks a set of markers on the runner's body (see Fig. 3) across a series of frames and records their respective positions in variables (see Video 2). These variables are then passed back into LabVIEW for data processing and presentation. The distance in pixels of each marker relative to a co-ordinate axis that is constant across frames is translated into a real world distance in inches. This information is used to draw conclusions about the stride length, back angle, foot position over time and heel height (see Video 3). A summary of the interaction between the coach and the TrackVIEW system is shown in Fig. 4. Finally, an overview of the TrackVIEW system is shown in Video 4.

This project was completed over a period of four months as part of the senior capstone course at Georgia Tech. It is currently in the alpha phase of development. TrackVIEW could not have been accomplished using a traditional programming language such as MATLAB or C++ in the timeframe of the course. Rather than build code from the ground up, the students were able to take advantage of the abstraction provided by LabVIEW and VBAI to accomplish such tasks. This advantage is particularly evident on the vision subsystem, as none of the students (who are all mechanical engineering majors) had any prior experience with video analysis or processing. The hardware also provided significant advantages to the project by removing the need for data filtration and conditioning. Furthermore, the use of LabVIEW blocks made data processing and presentation effortless. In the future, this project could be improved upon through the use of a more sophisticated video capturing device such as the Microsoft Kinect, which can accurately track markers and shapes across a series of frames.

Fig. 1: Custom aluminium footpad, shown without strain gages installed.

Fig. 2 TrackVIEW starting block showing installed footpad and NI hardware / software

Fig. 3 Runner on field with markers on body (see feet, knee, hip, shoulder) and starting block

Fig. 4 Conceptual overview of TrackVIEW starting block

Video 1 Starting block data acquisition and processing for reaction time and force on block

Video 2 VBAI program tracking markers across frames

Video 3 Analysis of runner, showing foot tracking, stride length and back angle

Video 4 Overview of TrackVIEW Project