- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

Contact Information

Year: 2016

University: University of Leeds (UK)

Team: Arturs Grigals, Mark Narvidas, Maksims Kuznecovs, Jack Brookes, Simon North,

Jake Smith, Rosie Smith, Declan Toyne, Alistair Malhorta, Chris Pritchard,

Menelaos Kanakis (2016); Stephen Worsley (2017)

Advisers: Prof. Martin Levesley, Dr Justin Gallagher, Dr. Andrew Jackson

Email: ProjectALANLeeds@gmail.com

Twitter: @RoboticRehab

Website: Robotic.Rehab

Project Information

Advanced upper-Limb Autonomous Neuro-rehabilitation (ALAN)

Project ALAN Arm Overview Video

Description

Project ALAN is a multidisciplinary team development aiming to create a commercially-viable rehabilitation device for use in of post-stroke patient therapy. This undertaking has also successfully delivered an advanced robotic testing solution to evaluate these rehabilitation-focused systems. Additionally Project ALAN presents the concept of robotics-enabled remote physiotherapy, which shows potential to allow wider access to post-stroke rehabilitation at much lower cost and higher efficiency than conventional therapy methods while addressing data security.

Why?

Stroke is most common cause of severe chronic adult disability. Within the United Kingdom, of the people who survive stroke, 85 percent are left with some degree of arm paresis [1]. After five years, 25 percent of these patients still exhibit some difficulty using their arm, which results in a large cost for the UK National Health Service (NHS) [2]. After stroke, rehabilitation facilities use physiotherapy to help patients relearn the lost motor functions by repeating meaningful coordinated movements. Having insufficient resources results in patients spending inadequate time undertaking rehabilitation activities, which can potentially limit the degree of recovery. Robotic rehabilitation systems can supplement conventional therapy services to increase the intensity and frequency of rehabilitation [3].

These medical systems are to be used with patients, such as rehabilitation systems, must be safe and reliable in order to ensure that no further injuries are caused, and are functioning as intended. The Medical Devices Agency, also known as MDA, is responsible for ensuring that all the safety regulations are met while at the same time approves and monitors clinical trials. This process involves a lot of approval and paper work, a long waiting time for feedback, and further suggestions that need to be implemented prior to commencing with trials [4]. Using robotic testing solutions for durability and validation can accelerate developments and time to market (TTM), in turn providing better care for those in need.

Challenge

Develop a commercially-viable rehabilitation device alongside a novel humanoid arm. The latter would act as an industrial testing solution and potentially a remote physiotherapy robotic system. Using these, create a uniform platform where the testing system can accurately mimic a variety of human patients for medical evaluation of rehabilitation devices, as well as investigate possibility of reusing the humanoid arm within the remote physiotherapy field. Most importantly, ensure all these sub-systems can communicate and exchange large amounts of confidential user data securely and efficiently.

Solution

Using National Instruments platform-based approach improve upon the myPAM rehabilitation device (myPAM) and create two independent design iterations of the humanoid arm to rapidly evaluate both industrial testing and remote physiotherapy prospects (ALAN-Arm). The project results show how a fully working rehabilitation device is being tested by a unique humanoid arm design. Due to having one unified platform, the team was capable to rapidly prototype a conventional humanoid arm design using the NI myRIO embedded device, develop the specialist knowledge-base and quickly progress to an industrial version based on the Compact-RIO. Reconfigurable I/O architecture and the scalable graphical design environment allowed to transfer large amounts of existing code base from one design to another seamlessly, saving time and reducing faults associated to software porting. Moreover, by turning to the community and existing LabVIEW solutions for data management and encryption, real-time control and data acquisition, the team was able to fully complete the project in under 9 months.

Products

|

Software:

|

LabVIEW 2015, LabVIEW Real-Time Module, LabVIEW FPGA Module, LabVIEW 2015 myRIO Toolkit, NI LabVIEW PID and Fuzzy Logic Toolkit, LabVIEW SoftMotion Module, NI DIAdem

|

| Hardware: |

NI myRIO-1900, NI cRIO-9022, NI cRIO-9122, 2x NI 9215, 6x NI 9505

|

| Other: |

4x Hitec HS-805BB, 6x AMS22B Rotary Position Sensor, 6x Maxwell 150W DC motors, 6x High-Precision Encoders (MR Type L) |

Overview

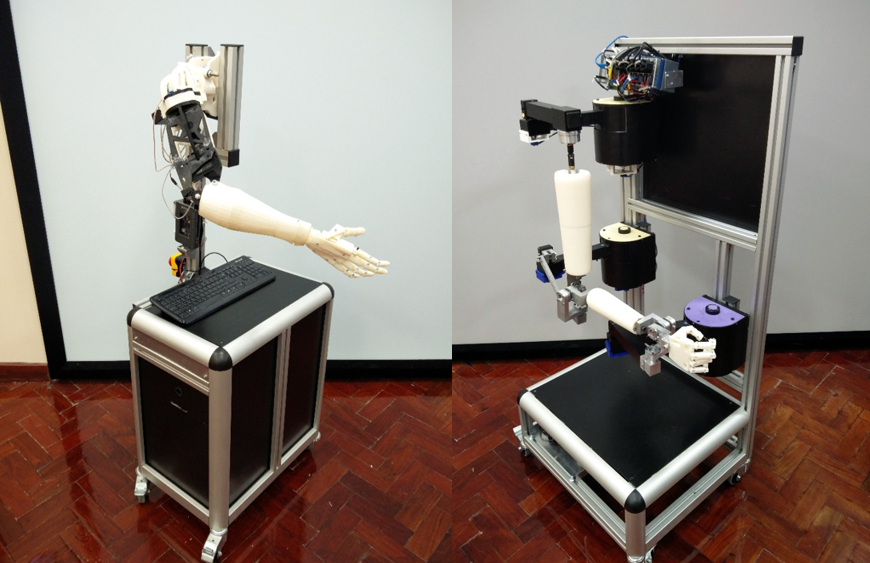

Project ALAN team worked on the myPAM 2.0 rehabilitation device and created two robotic humanoid arm prototypes for testing. The internally actuated robotic arm design (Prototype 1) was built according to the InMoov open-source humanoid robot. The second design iteration (Prototype 2) focused on a completely unique and novel externally actuated design approach that in the end has proven to be much more reliable for stress and durability testing and overall performance.

Overview of the Project ALAN systems that were developed

myPAM

myPAM 2.0 rehabilitation device is an assistive system to help post-stroke patients move their upper limb in a horizontal plane essentially acting as a physiotherapist. The device will allow the patient to have a wider range of movement and thus contributing to the reengagement of upper limb muscles. In addition, the device is designed to be compact and could be easily setup in the patients home and used daily.

ALAN-Arm

ALAN-Arm is an initiative to develop a state-of-the-art humanoid arm through two design iterations (Prototypes 1 and 2). It will act as a robotic testing solution for the myPAM device and lay the foundation for remote physiotherapy possibilities in the future. This, in turn, will accelerate the commercialisation process and enable the rehabilitation device to reach wider audiences delivering its unprecedented physiotherapy methods.

Prototype 1 Prototype 2

Internally Actuated Design (Prototype 1) Externally Actuated Design (Prototype 2)

Comparison of Prototype 1 (left), a person and Prototype 2 (right) using a rehabilitation device

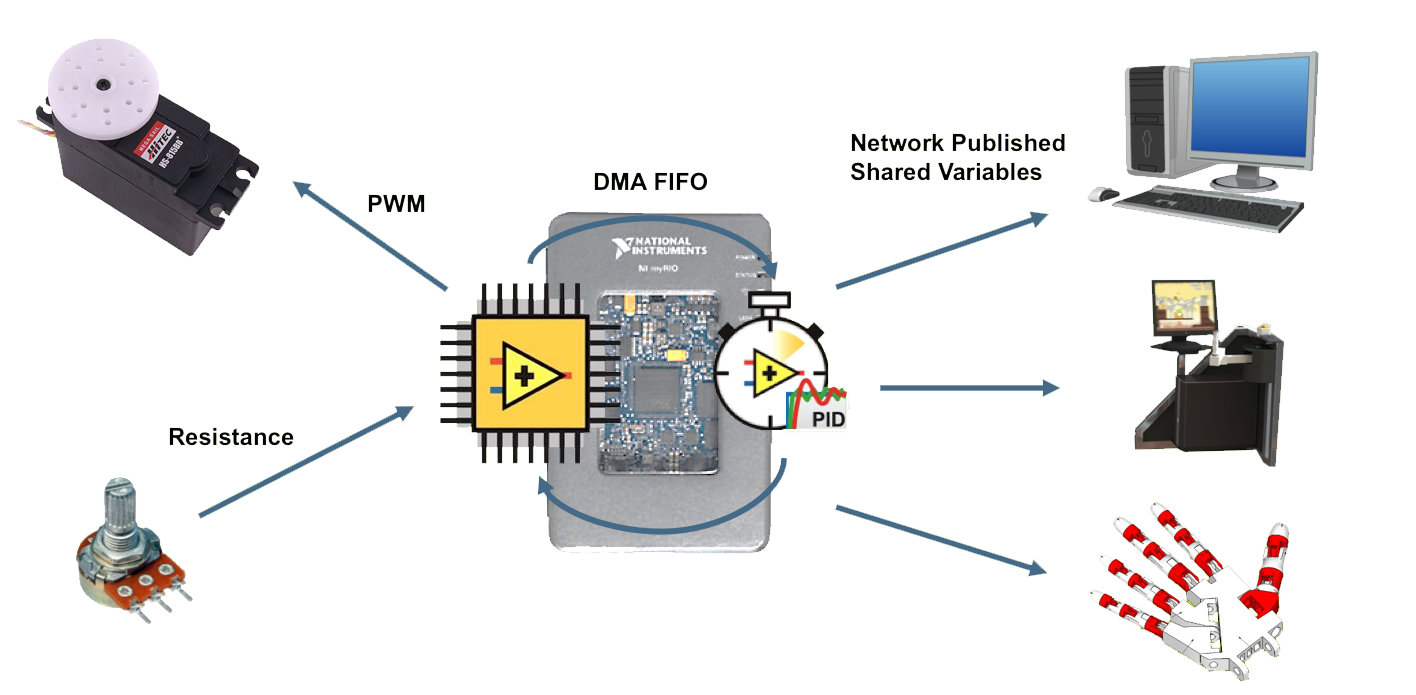

ALAN-Arm Prototype 1

Based on the open-source mechanical design InMoov, Prototype 1 followed a conventional humanoid arm approach with all actuators contained within the arm (hence the name of internally actuated design). It allowed the team to rapidly prototype the first iteration of ALAN-Arm and build the experience and knowledge foundation on humanoid arm manipulation. We have used the NI myRIO and developed a bespoke breakout printed circuit board to interface to four continuous rotation high-torque servomotor actuators as well as the positional feedback. The team based the software on two scalable software architectures for the Windows Host and LabVIEW RT/FPGA to allow for deterministic actuator control, data acquisition and kinematics calculations as well as a user-friendly graphical user interface (GUI).

Windows Host was developed using the Event-Driven State Machine with custom user-events. This architecture made the application consume little resources, as it would only “wake-up” on OS broadcast events (such as mouse clicks) or custom generated events (such as incoming front panel updates from the Real-Time target). This framework also handled communication to other network devices (such as additional robotic arms or the hand mechanism) and received data streamed, which it would process and log to a file on the host machine. Real-Time Host used a Multi-Loop Producer/Consumer architecture, where a number of independent loops would communicate to each other through buffered messages (Queues). Real-Time host was also communicating to the custom FPGA application, also running on the myRIO that was responsible for data acquisition and actuator control using the NI LabVIEW PID and Fuzzy Logic Toolkit.

The system is controlled using a mathematical model of the human arm. A desired position is sent to a set of kinematics calculations which calculate the best feasible elbow position out of a set of possible solutions predicted by the mathematical model. Afterwards, the four required joint angles to attain the desired arm configuration are calculated. These four angles are sent to PID controllers, which then calculate the required servo-motor Pulse-Width Modulation (PWM) based on the current position, as measured by potentiometers in each of the joints.

With the help of LabVIEW graphical design approach, we were able to quickly implement our human arm mathematical models and kinematics calculations on to the physical arm. The simplicity of adding new front panel objects to control and measure properties of the human arm model made development much easier, as things like 3D graphs allow us to see exactly the positions and movements of the arm in the model. LabVIEW environment has lead us from low-level PWM and PID implementations all the way to the Graphical User Interface, never having to re-learn the same programming concepts, accelerating our development time and helping us to reach our goals quicker.

The concept was successfully completed in several months and has proven useful for validation of mathematical arm modelling. It was found that it cannot satisfy all conditions for rehabilitation device testing, therefore based on the knowledge gained, the team focused on creating a more industrial solution.

Prototype 1 at the Leeds Festival of Science 2016 event

Prototype 1 high-level systems overview

ALAN-Arm Prototype 2

Due to the Internally Actuated Design (Prototype 1) limitations, we developed the second design. The Externally Actuated Design (Prototype 2) allowed us to address the accuracy, force and back-drivability requirements by using three powerful actuators to actuate the shoulder, elbow and wrist positions externally. This approach allowed to manipulate the myPAM 2.0 rehabilitation device whilst representing the shoulder, elbow and wrist positions with complex mechanical joints.

The arm is controlled by using LabVIEW, and a CompactRIO (cRIO) embedded controller. The cRIO has six NI 9505 modules, each of them powering an actuator which consists of 2 DC motors. This approach allows to have a modular design and save time due to the DC control solutions for the cRIO. Additionally, the cRIO’s onboard FPGA chip allowed us to have complex kinematics calculations done fast and reliably with determinism, which allowed to meet health and safety requirements to protect the device user. The actuator positional feedback from the system was acquired by using two analogue input (AI) modules (NI 9215) which acquire voltage readings from Bourn rotary sensors. The AI modules and the cRIO allowed to acquire sensor data with 12-bit resolution ensuring precise PID control responses of the arm. The latter has been implemented on the FPGA for added time-critical safety using NI LabVIEW SoftMotion Module, which also allowed us to implement advanced control features such as trajectory generation simply and robustly.

The kinematics use the same human arm model as Prototype 1. In this design, the human arm model is crucial, since we must ensure that the wrist, elbow and shoulder actuators do not ‘fight against’ each other, and always respect the physical linkage (upper and lower arm) between the robot end effectors. Instead of calculating four joint angles like in Prototype 1, we have to calculate six angles in total - two for each of the three robot manipulators.

Kinematics and control code was reused from both designs without modification across myRIO and cRIO platforms. Additionally, the ease of adding front panel elements meant the system could be made with huge customizability – all the PID values for each of the robots can be changed at run-time, allowing for tweaking and perfecting all parameters. Other visual aids such as 2D and 3D graphs were used to represent the arm positions on the user interface allowing to validate arm position compatibility and display the workspace for each actuator therefore significantly accelerating the prototype-testing phase.

Prototype 2 at the Leeds Festival of Science 2016 event

Prototype 2 high-level systems overview

Screenshot of Prototype 2 graphical user interface

Secure IoT Communications

The project also explored the possibility of allowing for remote rehabilitation using multiple interconnected humanoid arms and physiotherapy systems (Internet of Things). This is when patients can perform their movement exercises at home, and have all their progress securely streamed over the Internet which can then be used for assessment and monitoring of the patients. The team looked into how these large amounts of data can be collected from the rehabilitation device, transmitted to the therapist and processed efficiently. The team was able to create a Hardware Abstraction Layer (HAL) around the humanoid arm to ensure physical safety of the device as well as implement encryption on all messages sent to ensure secure communications of large and confidential data that would be exchanged.

Home-based robotic physiotherapy concept explained

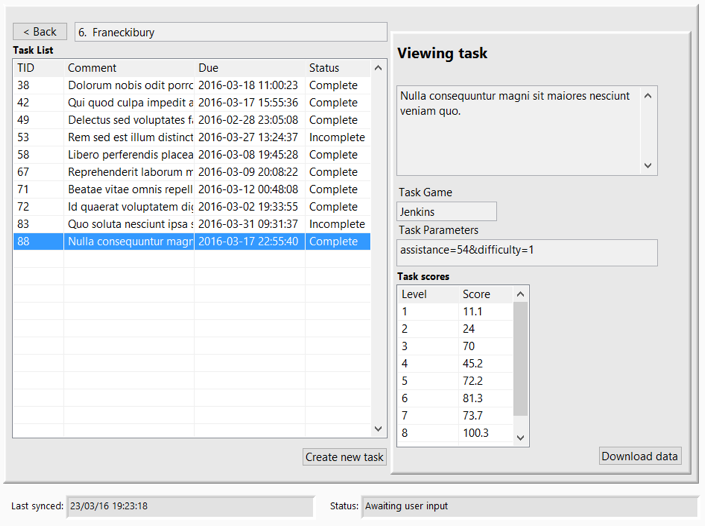

Using the LabVIEW Database Connectivity Toolkit bespoke modules were developed to store data about patients’ exercise sessions – such as time, length or their performance in the game or activity. With this data, physiotherapists can make judgements about the patients’ level of progress in their rehabilitation without the time burden of having to meet with the patient face-to-face. While in development NI DIAdem has proven invaluable for searching and analysing large amounts of session data. Similarly, on the end-user side, physiotherapists can view patient data via a custom Graphical User Interface, which shows statistics about their sessions, and even allow them to remotely assign tasks to the patient – which would then appear on the patient’s rehabilitation device. The interface also allows physiotherapists to download the movement data, including hand, elbow and shoulder position of the patient throughout their activities, and re-play the data on the humanoid arm.

Screenshot of Physiotherapists’ user interface developed in NI LabVIEW

A further use of this system would allow for faster and higher quality research to be performed. Researchers could use volunteering patients’ data to collect evidence of what influences motor learning in people with upper limb impairment. For example, different levels of robotic assistance could be assigned to patients. Through analysis of collected data, we may obtain an insight into the factors that contribute to a faster recovery of motor skills - ultimately helping the future development higher quality rehabilitation systems.

In conclusion, Team ALAN delivered two humanoid robotic arms that will accelerate the development of robotic rehabilitation systems and remote rehabilitation. This would not be possible without the help of a unified software and hardware platform which saved time, provided a plug-and-play environment and ensured fast mathematical calculations.

Project ALAN for the Community

Following our findings from Prototype 1, team Project ALAN is very happy to announce that we are releasing all of our LabVIEW source code for the InMoov mechanical design control. The code bundle includes LabVIEW FPGA (Servo Actuation and Data Acquisition), Real-Time (Data Processing and Inverse Kinematics) and Windows Host (Control Demo and Workspace Calculations using Forward Kinematics). This will allow tinkerers, hobbyists and researchers to individually explore the development of the 3D-printed open-source mechanical design inMoov. We hope that this will come as a great contribution to the impressive collection of maker movement inspired projects already available for LabVIEW at https://www.labviewmakerhub.com/ and will help the community to innovate quicker in humanoid robotics and field of prosthetics.

Project ALAN Recognition

[07/07/2016] Project ALAN at New Designers

[01/07/2016] Project ALAN at the IET International Robotics Showcase

[25/06/2016] Project ALAN at the UK Robotics Week

[21/04/2016] The Voice of 3D Printing Technologies - 3D Print.com writes about Project ALAN

[18/04/2016] Helping to inspire women in engineering at the University Technical College Leeds event

[23/03/2016] Project showcased at the British Conference of Undergraduate Research (BCUR)

[19/03/2016] Undertaking presented at the Leeds Festival of Science (Be Curious) event

[14/03/2016] Project ALAN Lends a Hand to Hilary Benn at the New UTC Leeds Construction Site

[11/02/2016] Project ALAN at the University of Leeds project showcase wins four nominations

[04/02/2016] Project ALAN presented at the Houses of Parliament

Nominate Your Professor

Team ALAN would like to nominate Professor Martin Levesley. Professor Levesley continuously ensures that students have the best tools in the universities curriculum to ensure employability and skills development necessary for future engineers. This involves the development of mechatronics projects where students use the NI cRIO and myRIO alongside LabVIEW to control a custom student designed buggy over a rough terrain. In this way students have practical experience in using control theory outside of lectures with industrial standard software and hardware.

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

An incredible project that highlights the positive impact that Engineering has on society! I look forward to reading more as you guys complete the submission. Keep up the great work!

Senior Marketing Engineer, National Instruments

Connect on LinkedIn: https://www.linkedin.com/in/richard-roberts-4176a27b/

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Realy enjoyed seeing ALAN start to come together at the Leeds Showcase, congratulations on your prizes!! Project Alan is looking great, I'm looking forward to seeing more as we progress !!

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Seeing the team start the project from scratch and looking at how much they've accomplished within months is really a feat to be proud of. Good job and all the best in the competition!

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Looking very good! Its nice to see the progress of this.

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Looking forward to seeing some updates from the Be Curious event. Keep up the good work!!

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Thanks for sharing the videos from Be Curious, they are fantastic! I have had plenty of very positive feedback from the general public and other staff presenting at the event, you did a fantastic job! Congratulations also to Menelaos for his presentations in Parliament and at the BCUR event in Manchester.

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

It's really great to see the project coming together so well. It's an incredibly interesting project and I'm really excited to see where it goes from here. Well done!!!

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Congratulations for your promising design. Congratulations to Menelaos for his presentation in Parliament as well. Make us proud.

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Many thanks team ALAN for being part of the "UTC Leeds" event yesterday evening. Exciting projects like this are a great way of encouraging more women to consider engineering, The girls coming to the new school and their parents really enjoyed the demos you did and the "Build an ALAN Hand" activity. Fay Best from WISE (@faybest13) was very impressed.

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Congratulations to Menelaos Kanakis for presenting his individual contribution to the project at the House of Parliament and at the BCUR conference. We hope to see a publication in an international conference soon. Good luck!

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

I would say that this is a "quite reasonable" project which clearly will have an immense impact on the lives of those who have the privelege of using it.

Applications Engineer

National Instruments UK and Ireland

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Its great to see a project and a working prototype that combines technology / rehab and can really HELP and make a change in people lives and quality of life.

Rehabilitation takes time this prototype is very promising because it will accelerate the rehab process and at the same time enable specialist to have access to data that it was not possible to have in the past. This will also help the adaptation of specific therapy / custom therapy according to the patient real need. Great work!

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Awesome project! It can be clearly seen that there was a lot of effort that went in to making the project both highly functional and extremely user friendly. Really great job!

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Fabulous work. The kinematic software algorithms for this are very difficult. To achieve 2 innovative devices, software control and evaluation in such a short time is a great feat! Good job! Looking forward to see where this goes next.

Director of Key Engineering Solutions Ltd

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

This is a great piece of work, so may different aspects have been brought together in a fantastic project that will be of great use going forward as a means of testing upper-limb robotic rehabilitation systems. Good work!

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Really looking forward to seeing the completed project ALAN at the Robotics Open Day in Leeds on Saturday 25 June to mark the opening of of the UK Robotics Week 2016. A great oportunity to showcase what you have achieved to the general public. I know they will love it!!

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Congratulations! This is definitely not a simple project. From your presentation, I can see your great engineering capability and proficiency in NI platform. In addition to these, your marketbility and social impact of ALAN are also pretty good. The remote rehabilitation is an extremely interesting topic, I'm looking forward to your solution on this. See you in NIWeek.![]()

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Well done on another very successful public engagement event to mark the start of national robotics week. The new games interface looks great and there was some great coverage on social media @RoboticRehab. Particularly liked it when Project ALAN met Alan, he seemed to really enjoy it. Looking forward to the IET grand finale in London on Friday!

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

I released some code that does Trilateration calculations, which is used in the kinematics for Project ALAN - available here https://decibel.ni.com/content/docs/DOC-48142

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

ALAN seemed to be very popular with photographers, journalists and others at the Institution of Engineering Technology robotics showcase. Nice to be demonstrating NI technology in London and some great pictures on social media. Well done Mark and Jack for manning the demo

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Wonderful. Well doneTeam ALAN. Being a former Ph.D. student in MechEng of Leeds Uni, this makes me proud! Congratulations to every one specially Prof. Martin Levesley, Dr Justin Gallagher, Dr. Andrew Jackson for their untiring efforts.

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Congratulations to ProjectALAN for winning the Global Student Design Competition, announced at NI week in Austin