- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

Contact Information

University-department:University of Nottingham,UK - Mechanical Engineering

Team Member(s): Bilal Ali, Ebad Naqvi, Hoang Le, Kishen Rengaraj

FacultyAdvisors: Dr Guy Charles

Email Address: rajabilal14@hotmail.com, eaybsean@nottingham.ac.uk, eaybhl@nottingham.ac.uk, eaybkr@nottingham.ac.uk, epzgc1@nottingham.ac.uk

Project Information

Title: Performance Dynamometer with Motor Car Model

Description:

A Dynamometer is designed to test the performance of Formula Student car and a Graphical User Interface (GUI) is written using Labview. The concept is validated by building a quarter scale model and to validate the GUI a Labview controlled motor car model is also built.

Products:

Software from NI:

Development System: Labview 2010

Modules: Real Time and FPGA

Toolkits: PID and Fuzzy Logic, Report Generation, Sound and Vibration

Other software:

Abaqus

Matlab/Simulink

Pro-Engineer/Pro-Mechanica

Host OS: Windows Vista/ 7

Hardware from NI:

NI USB-6009

NI cRIO 9022

NI 9215

NI 9505

Other hardware:

DC Brushed Motor

Hall Effect Sensor

Thermocouple (J-type)

Power Supply

The Challenge:

The Formula Student team needs a means of accurately measuring the performance characteristics (torque and brake horse power) of its race car. To fully assess the performance, the performance ratings should therefore ideally be taken at the wheel of the car so actual road going performance can be deduced. Another important requirement of the project is that the performance characteristics should be measurable at different gear ratios for the entire band of engine speeds. For these measured characteristics an acceptable level of accuracy is also needed to interpret the overall performance.

The measured performance characteristics should also be plotted on a graph/table and therefore should be comparable to previous readings. To successfully analyze the performance characteristics of any car in reference to any recent changes,the performance readings runs should be repeatable and adjusted/corrected for any possible factors that might change the output.

The design that is required should also be portable that means that on track days any changes that are done on the car should be easily analyzed. A prime design factor is that the product should be able to measure the performance characteristics of different race cars (track lengths and power).

The Solution:

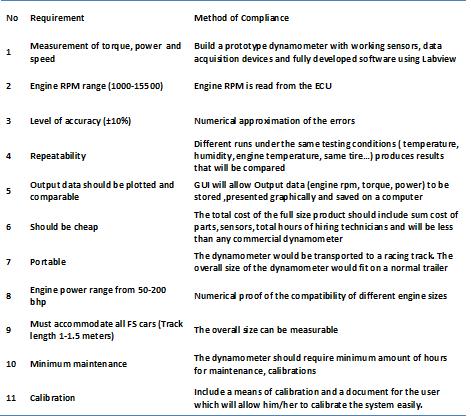

For our given requirements, the best possible solution is a performance dynamometer. A dynamometer is specialized mechanical instrument for measuring the moment of a force (torque), the rotational speed (RPM) and the power output (Bhp). Given below in Table 1 are an outline of the different requirements and their method of compliance with reference to the dynamometer as a solution.

Table1: Requirements and their method of compliance

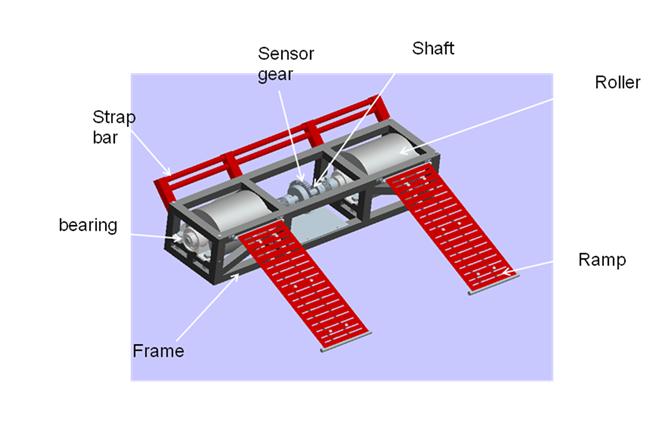

The Final Design of the Dynamometer:

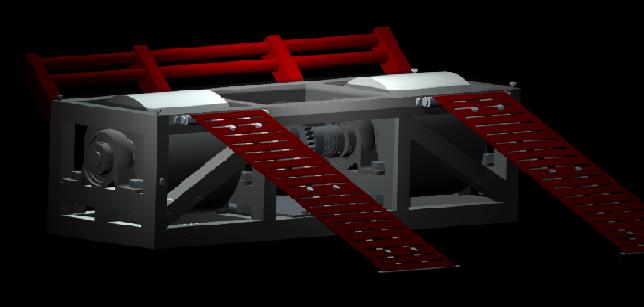

Figure 1: Final Design of the Dynamometer

Basic working principle of the design:

It measures the torque and power delivered to the rollers via the wheels thus incorporating the losses in power in the drive train. It consists of a fixed inertial mass (two rollers) which is driven by the wheels of the car. The power required to accelerate this known mass is calculated from the torque produced at the surface of the rotating mass which is calculated by measuring the acceleration of the mass and its known inertia.The data achieved from a test run is presented in the form of graphs which can then be analysed to check the engine’s performance. Typically torque or horsepower against the rpm of the engine is plotted which can show characteristics such as the peak torque or the peak horsepower produced by the engine at a specific rpm.

The Graphical User Interface:

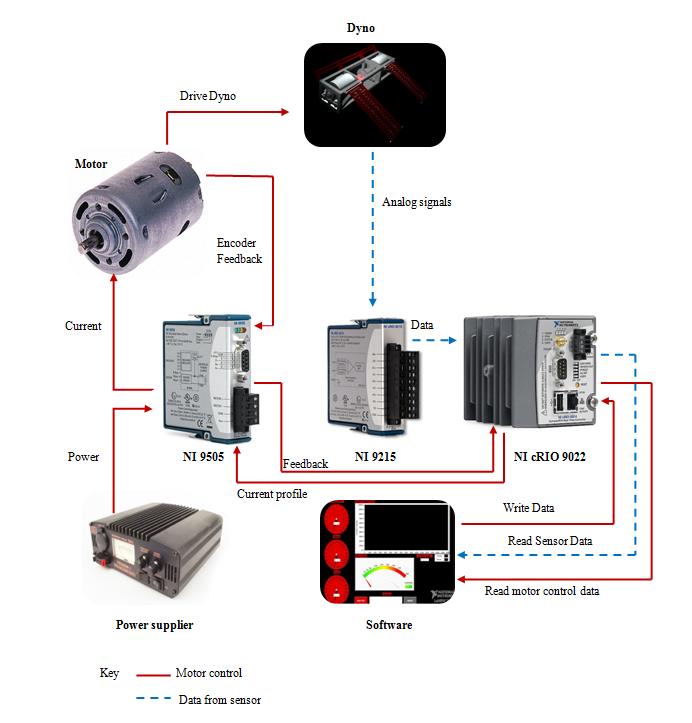

Data acquisition process:

Figure 2: DAQ Process for the Dynamometer

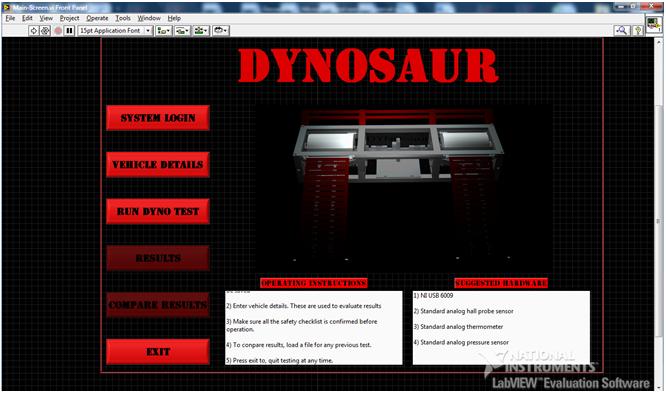

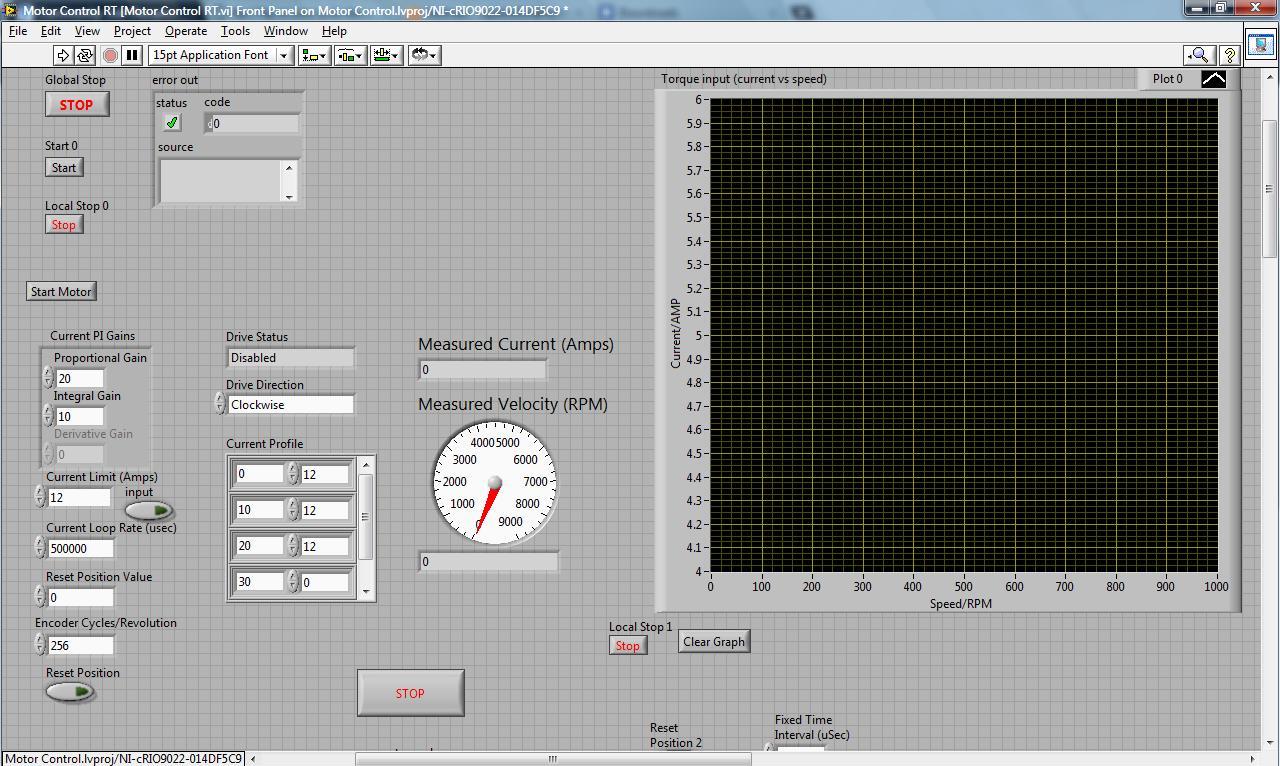

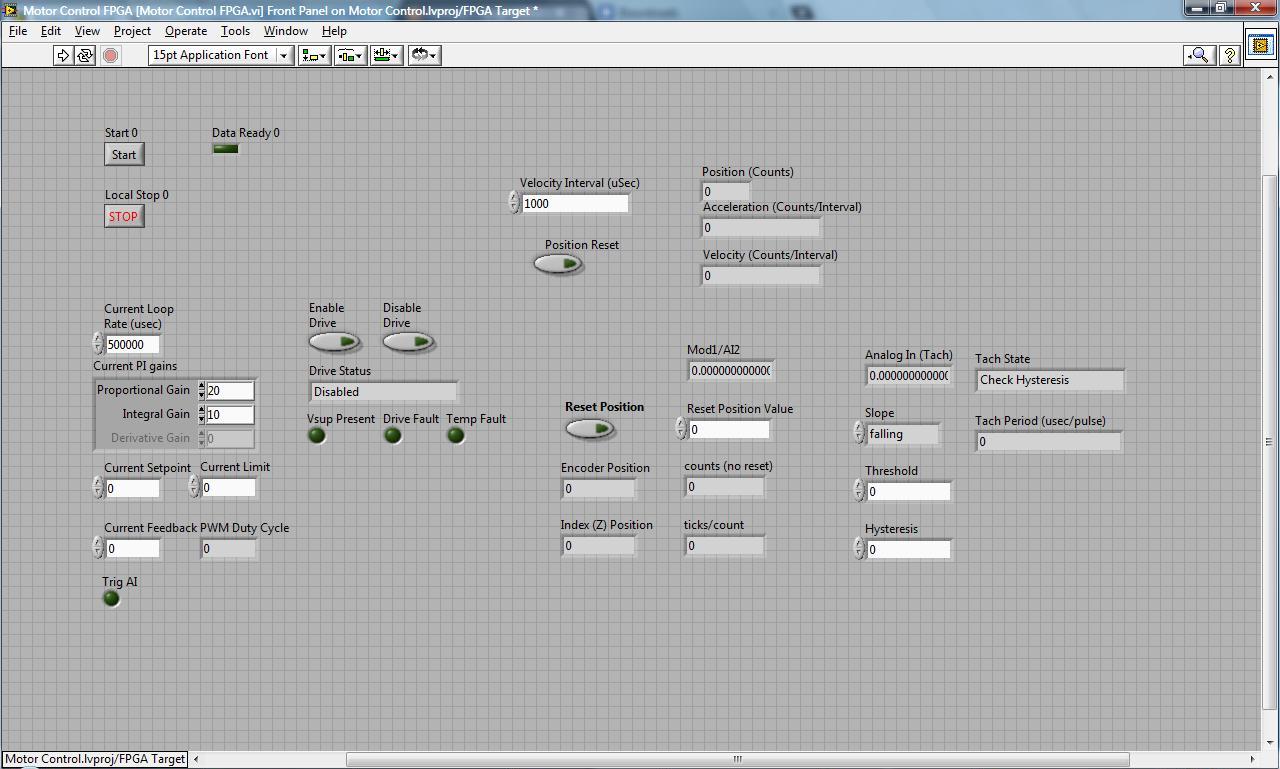

Snapshots of the Front Panels:

Figure 3: Main Screen Front Panel

Figure 4: Test Screen Front Panel

Validation of the Design - The Quarter Scale Prototype:

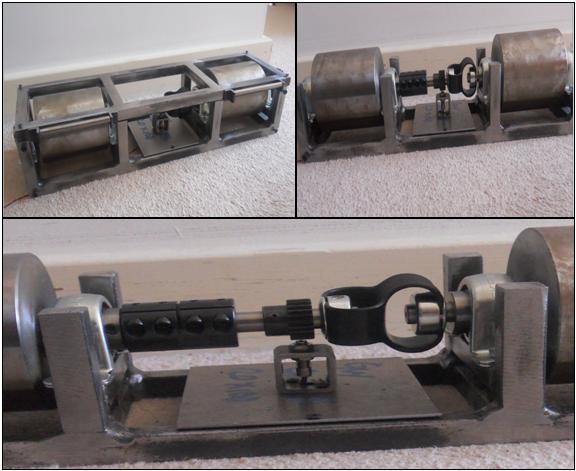

In order to validate the working concept, a prototype is manufactured.Some of its images taken during manufacturing and testing stages are shownbelow:

Figure 5: Prototype during manufacturing stage

Validation of the GUI - The controlled Motor car model:

To validate the working of the main GUI a quarter scale motor car was built which is controlled by Labview. The motor car simulates an IC engine and drives the rollers following a specifically given profile. The results produced from the main GUI are then compared with the inputs for validation purposes.

The overview of the data acquisition and command process for motor controller is shown below followed by the front panel snapshots of both real time and fpga vi’s.

Figure 6: Motor Control DAQ Process

Figure 7: Motor Control RT Front Panel

Figure 8: Motor Control FPGA Front Panel

Fully Developed Quarter Scale Prototype with Motor Car Model:

Figure 9: Front view of the Final model

Figure10: Top view of the Final model

Figure 11: Dyno Solo

Figure 12: Full System setup

Sample Test Video:

Final Product Attributes:

- Measures 200+ BHP

- Product costs only 25% of commercial dynamometers

- Complete software package with GUI (Results tabulated and plotted)

- Modular design and upgradeable

- Maintenance and calibration free

- Can be used for any Formula Student car and 90% of commercial vehicles

Benefits of NI instruments and Labview:

Using NI instruments and Labview allowed us to develop a graphical user interface for our application. Also it enabled us to validate the concept of the designed system in an accurate and reliable way. It eliminated the necessity of building a full scale product and validating it by running a vehicle on it thus reducing the costs by a huge margin. Manufacturing a full scale model could have cost six times more than the small scale. Also it saved a lot of time and most importantly eliminated a range of risks associated with the full scale model.

In short, Labview and NI tools provided us a powerful platform where we were able to develop our application very quickly and easily according to our requirements.

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Hello there,

Thank you so much for your project submission into the NI LabVIEW Student Design Competition. It's great to see your enthusiasm for NI LabVIEW! Make sure you share your project URL(https://decibel.ni.com/content/docs/DOC-16521) with your peers and faculty so you can collect votes for your project and win. Collecting the most "likes" gives you the opportunity to win cash prizes for your project submission. If you or your friends have any questions about how to go about "voting" for your project, tell them to read this brief document (https://decibel.ni.com/content/docs/DOC-16409). You have until July 15, 2011 to collect votes!

I'm curious to know, what's your favorite part about using LabVIEW and how did you hear about the competition? Great work!!

Good Luck, Liz in Austin, TX.

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Excellent stuff!! great project,congratulations!

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Thanks Frank. We considered M2 bolts, but we had to maintain the geometry of the design!! LOL!

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Hi guys,

Please don't forget to vote our project by clicking on 'like' at the bottom of the project and also giving us some stars!!!

For more information on voting visit: https://decibel.ni.com/content/docs/DOC-16409

Thanks

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

damn good!!!!!

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

great project, someday i try

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Come on guys, to use your knowledge to science & technology study is the best way for you to develope your career. Good job!

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Hi there, cool design especially for students. Good job, congratulation

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

It's good idea & design for this project. I like the concept of this project

It will be perfect if the performance characteristics can be recorded by software as overlay data/trends of the same car for comparison next time

Well done team!