- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

NI WorldClass - Senior Students Programming Mobile Robots Using NI Compact RIO

Contact Information

| University: | Various universities from Germany, Austria and Switzerland |

| Department: | Electrical Engineering, Mechanical Engineering, Computer Engineering, Mechatronics, Physics, Math |

| Team Members: | Various Bachelor and Master students |

| Faculty Advisors: | NI Germany employees from Event Marketing, Human Resources, Applications Engineering, Academic Team |

| Primary Email Address: | fragen@niworldclass.de |

| Primary URL: | http://www.niworldclass.de |

| Primary Telephone Number: | +49 (0)89 7413130 |

Project Information

Project Title

NI WorldClass - Senior Students Programming Mobile Robots Using NI Compact RIO

The NI Worldclass 2009 took place from March 10-15 in a venue located 120km south of Munich in the Austrian alps. An intensive application process addressing all universities across Germany, Switzerland and Austria started as early as April 2008. In December 2008 20 candidates were selected and invited to form the four teams of the NI WorldClass 2009. Customer education for LabVIEW Basic 1 or 2 was provided early in 2009 in order to have the candidates "up and running".

Parts List

| Robotics Platform | Embedded Controller | Host System | Sensors & Actuators |

|---|---|---|---|

| 1x Fraunhofer VolksBot® RT 3 3-wheeled mobile robot | 1x NI cRIO-9014 Real-Time Controller | 1x NI PXIe-8130 2.3 GHz Dual Core Controller | 1x Stingray 146B AVT Camera Digital IEEE1394b |

| Dimensions: 580 x 520 x 315 mm (l x b x h) | 1x NI cRIO-9104 cRIO-Chassis 8 slots, 3 Mio. Gates | 1x NI PXIe-1062Q 3-HE-PXI-Express-Chassis | 1x MEMS Inclination Sensor |

| Weight: 13kg (excluding control PC and batteries) | 2x NI 9505 DC Brushed Servo Drive with Encoder Interface | 1x NI PXI-6229 16-Bit, 250 kS/s, M-Series DAQ | 1x Light Trap |

| Wheels: 260 x 85 mm, 200mm caster-wheel | 1x NI 9411 Digital Input, 6 Channels, 500 ns, +/- 5 to 24 V | 1x NI PXIe-5673 6.6 GHz Vector Signal Generator | 1x Strain Gauge Sensor |

| Gear ratio: 74:1 | 1x S.E.A. cRIO xLAN Module with switching function (100 Mbit/s) | 1x NI SC-2345 Shielded Carriers for SCC Modules | 2x Miniature servos |

| Max. speed: 1,4 m/s | 2x NI SCC-SG04 Strain Gauge Input | ||

| Max. Payload: 40kg | 1x NI SCC-AI01 Analog Input 2-Ch (42 V, 10 kHz) | ||

| 2x Maxon Motors 150 W, DC, shaft encoder, planetary gear: ratio 74:1 | 1x NI CVS-1456 Compact Vision Systems, IEEE 1394 |

Challenge

Use NI LabVIEW to program mobile robots that collaboratively master an obstacle course in only 5 days with team members you have never met before.

Solution

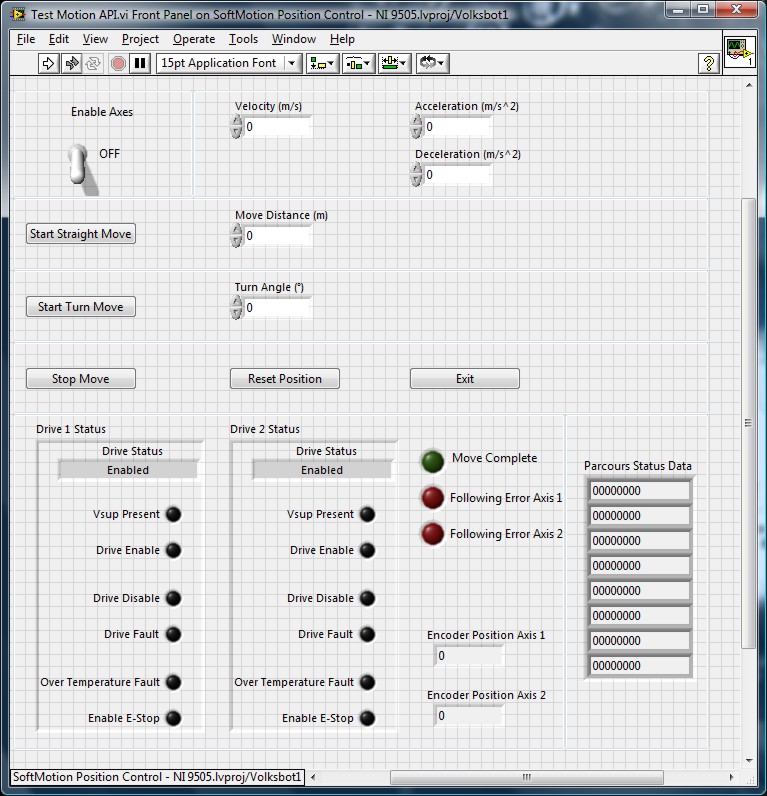

A pre-build motion control API and a remote control host program was provided enabling the teams to experiment with the mobile robot platform and executing basic motion commands. The API represented basic pre-compiled FPGA VIs that served as building blocks of all motion commands throughout the entire project. like Initialize, Load Constrains, Stop, Status, Straight Move, Turn Move, etc. without the need to program the FPGA immediately from the start.

Figure 1: Motion API for NI WorldClass

Figure 2: Host Application to Test Motion API for NI WorldClass

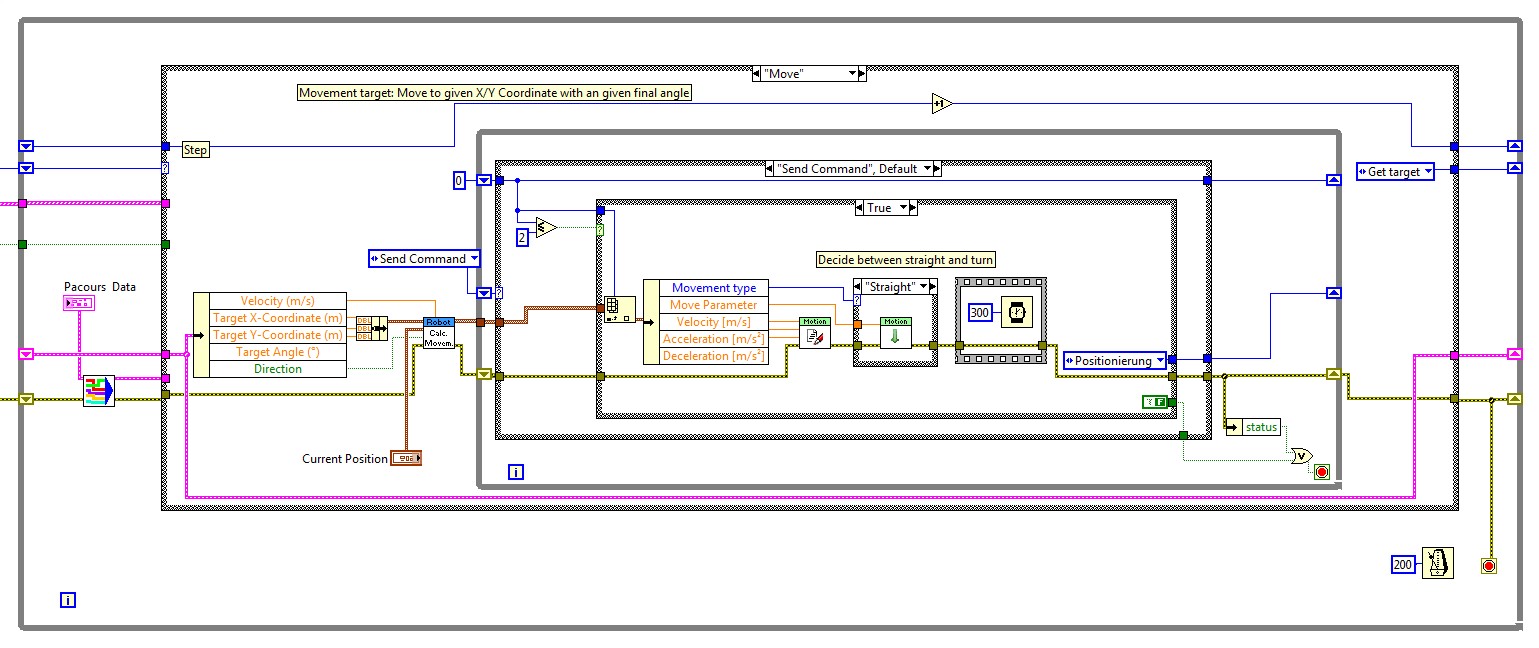

Over the course of five days all four teams needed to be able to develop an application running on the cRIO Real-Time system that was able to communicate with the Motion API running on the FPGA and at the same time receiving a bit stream with various process data. The bit stream contained position information for the individual robots and conditions of the various sensors and actuators. In order to have a flexible and maintainable system that could easily adapt to the ever increasing complexity of the overall system, al teams choose to develop a state machine. Different frame works for a state machine were designed but the common functionality across all teams included loading of xy-move coordinates, position correction and a master-slave behavior in order to be able to master the obstacle course in a collaborative apporoach with a partner team.

Figure 3: General State Machine Approach

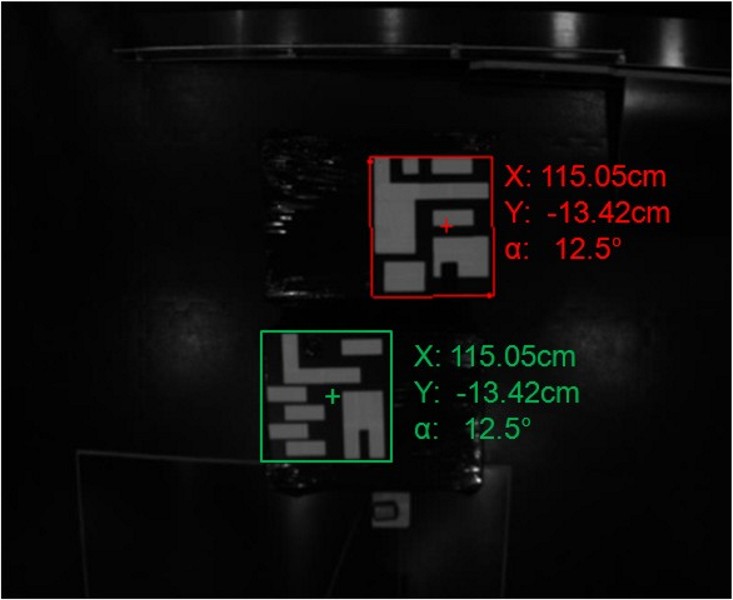

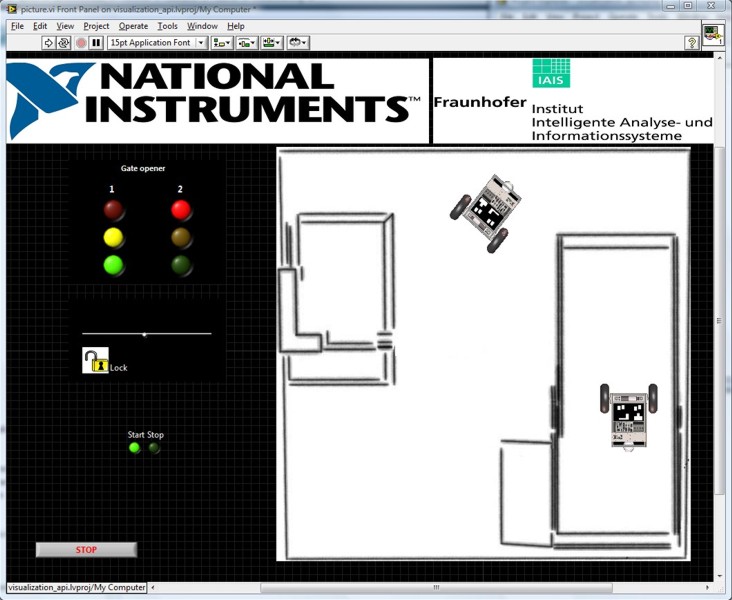

Besides the robot program itself, several applications needed to be developed to interface with sensors and actuators, vision inspection, communication and visualization. All candidates were asked to volunteer for temporary sub-teams that focused on a particular challenge at hand and thus being able to deepen their skills and technical expertise. The results and work of the sub-teams were than integrated by all teams into their individual solutions.

Figure 4: Vision Inspection showing Robot Positions

Figure 5: Visualization of Obstacle Course

NI WorldClass 2009 Impressions

Figure 6: Obstacle Course

Figure 7: Fraunhofer Volksbot R3 and NI Compact RIO

Videos of NI WorldClass 2009

Part of the challenges the candidates were facing was to create a team and project video. Below are the four videos created by the teams of the NI WorldClass 2009.

If links are broken please use the general youtube link for NI Worldclass: http://www.youtube.com/user/NIWorldClass

Team Anne Team Janne

Team Vroni Team Toni

Ingo Foldvari

Area Sales Manager - US West Academic

National Instruments