- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

vibration time Synchronous averaging

07-30-2012 12:47 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hello

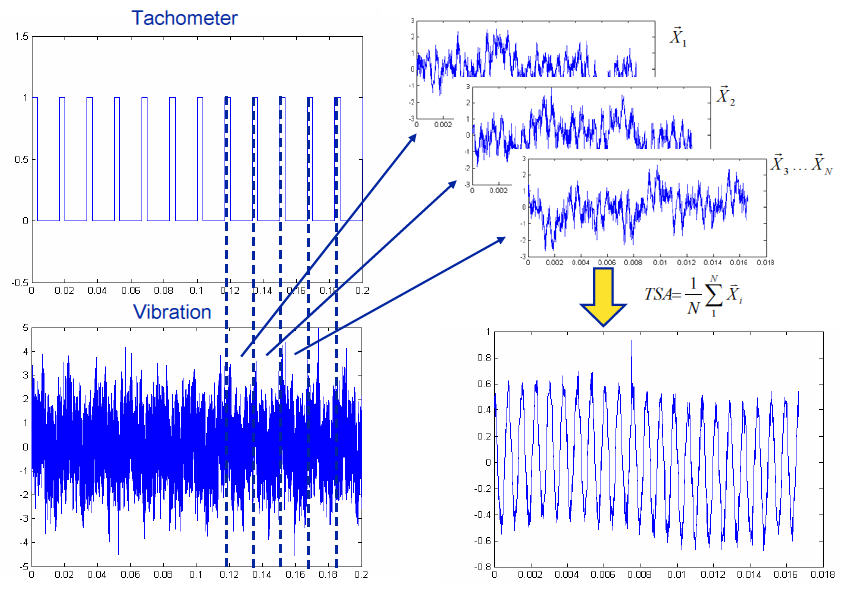

I have project to time sychronous average of gearbox signal, the signal from accelerometer is segmented every certain shaft rotation, the rotation of shaft is measured using tachometer, then the segments average, the whole process is shown in image below, could please provide some hints on how to apply this in labview

07-31-2012 03:58 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

it seem no one come accross this post, I am wondering if can use trigger for this purpose and how to to signal segmentation

Regards

07-31-2012 05:37 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hey Faris

To make any meaningful suggestions I think we need a bit more info from you. What are you using to aquire your data? is it in DAQmx or Real-Time?

The way I would implement this however is a producer consumer type architechture. Your producer loop would be continuously aquire your vibration data and then write it to a queue. Your consumer loop would then be reading your tachometer and dump the contents of the queue into an array that could then be processed somewhere in the code.

hope that gives you a starting point.

Applications Engineer

National Instruments UK

www.ni.com/ask

07-31-2012 06:44 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Thank TrottM for replay

to make it Clear; I use DAQmx to acquire the data. And I need to average together a series from signal segments ( vibration signal) each corresponding to one period of synchronizing signal ( tachometer signal which indicated one rotation of the shaft completed). In another words constant no of samples will be acquired at each shaft rotation and then this samples added to previous samples from previous shaft rotations, and then divided by the total no of shaft rotation. so the problem how to acquire same no of the points at each shaft rotation and then how to do segmentation.

Regards

07-31-2012

06:58 AM

- last edited on

03-25-2025

09:40 AM

by

![]() Content Cleaner

Content Cleaner

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

from the sounds of it you are after something along the lines of this then.

Your trigger would be the tachometer and the the vibration data would be your analog input

This would have to assume that the tacometer is at a constant velocity to ensure that the number of samples is the same however you do this though. This is beacause you are using a clock that is not tired to the tachometer for your acquisiton.

One way round this that I have seen is to use a second tachometer that produces many more pulses per revolution on the same mounting point as the first so that you have an external clock that is sychronised.

Applications Engineer

National Instruments UK

www.ni.com/ask

07-31-2012 07:27 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Have a look at the ADDON sound and vibration vis.Sounds like order analyses ...

If the rotational speed is constant you can use the Threshold detector vi to get the indices of the tacho pulses , use that data to slice the vib signal and avarage them.

If the tachosignal is not constant more math is involved. What needs to be done is a resampling of your signals .

Henrik

LV since v3.1

“ground” is a convenient fantasy

'˙˙˙˙uıɐƃɐ lɐıp puɐ °06 ǝuoɥd ɹnoʎ uɹnʇ ǝsɐǝld 'ʎɹɐuıƃɐɯı sı pǝlɐıp ǝʌɐɥ noʎ ɹǝqɯnu ǝɥʇ'

07-31-2012

08:19 AM

- last edited on

03-25-2025

09:40 AM

by

![]() Content Cleaner

Content Cleaner

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

thanks Henrik and Matt,

Matt - your triggered acquisition method works well for steady state speed machines - where the speed does not vary. With a controlled speed machine (without speed changes) it is possible to calculate the number of samples and sample rate such that you get very close to an exact integer number of rotations and then can segment the block into rotations and average against each other.

Henrik - you are correct, that if speed changes, even just a little bit, order analysis (Sound and Vibration Measurement Suite), https://www.ni.com/en-us/shop/product/labview-sound-and-vibration-toolkit.html, has a function that takes samples measured in time (what DAQmx does - 102400 samples per second for example) and re-samples them to angular position of the shaft, (360 points per revolution for example). Then it is easy to perform time synchronous averaging on a rotation by rotation basis, even with a continious stream of data.

Of course, bearings produce non-synchronous vibration, and TSA will remove bearing signatures. It is good for syncrhonous signals. However, if you perform TSA, and then subtract the TSA average from the original signal (on a rotation by rotation basis, you now have the bearing signals and noise left over. This is useful when the gear mesh vibrations are "loud" and you also want to evaluate the bearing signatures.

Good Luck!

Preston

Solutions Manager, Industrial IoT: Condition Monitoring and Predictive Analytics

cbt

512 431 2371

preston.johnson@cbtechinc

07-31-2012 08:37 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Homework?? However ..

Henrik

LV since v3.1

“ground” is a convenient fantasy

'˙˙˙˙uıɐƃɐ lɐıp puɐ °06 ǝuoɥd ɹnoʎ uɹnʇ ǝsɐǝld 'ʎɹɐuıƃɐɯı sı pǝlɐıp ǝʌɐɥ noʎ ɹǝqɯnu ǝɥʇ'

07-31-2012 09:02 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

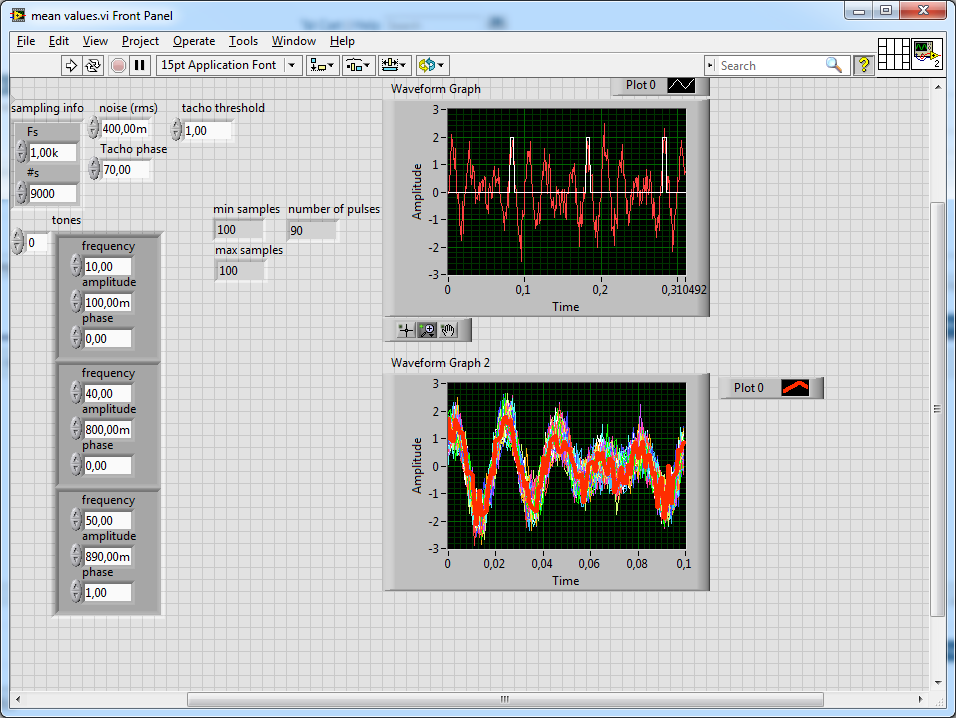

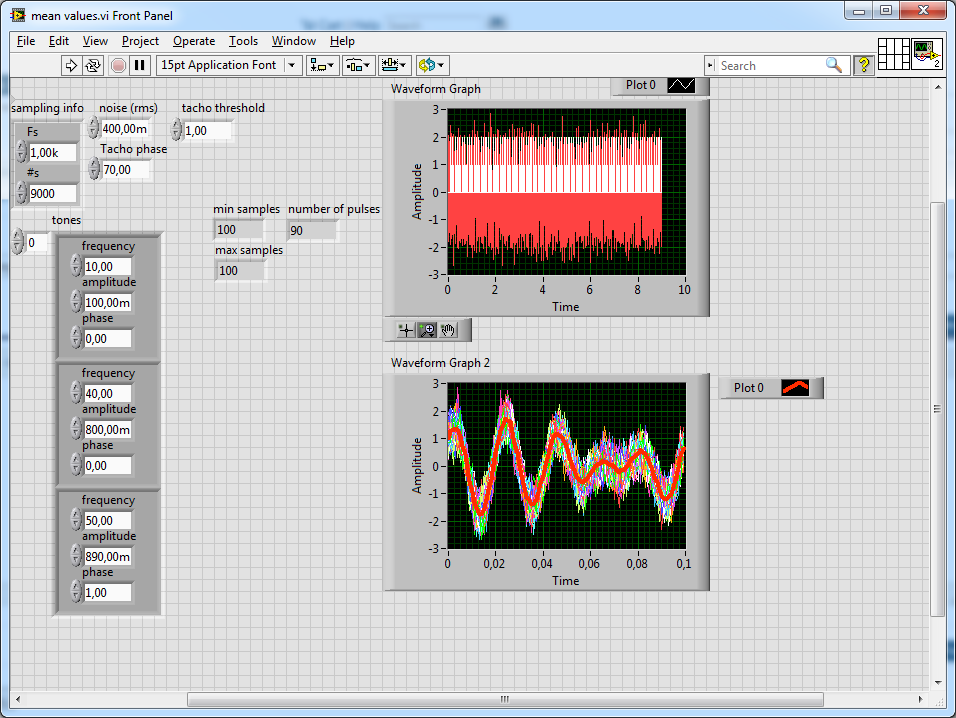

ups there was a bug in that quick shot .....

here the corrected version ...

Henrik

LV since v3.1

“ground” is a convenient fantasy

'˙˙˙˙uıɐƃɐ lɐıp puɐ °06 ǝuoɥd ɹnoʎ uɹnʇ ǝsɐǝld 'ʎɹɐuıƃɐɯı sı pǝlɐıp ǝʌɐɥ noʎ ɹǝqɯnu ǝɥʇ'

07-31-2012 10:31 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

thank you all for these helps, Henrik could you please send the file in 8.5 version as I use old version