- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

How can I adjust an emergency stop button for whole the programm

07-12-2013 01:53 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi!

How can I design an emergency stop button In this program to stop immediately?

thanks

07-12-2013 02:41 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@Labviewq8 wrote:

How can I design an emergency stop button In this program to stop immediately?

You need to share your program, so that we can get insight of design/framework...!!

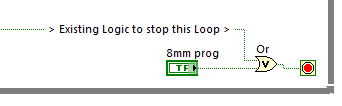

If its just a single loop, then the program can only be stopped after the current iteration will be executed, for that you may take OR of this boolean (8mm prog) and the existing logic to stop the loop, as shown below:

Other option (one should avoid taking this route) could be, using 'Abort VI' invoke node.

There may be other options available, but best can be suggested only after seeing your code.

07-12-2013 02:56 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

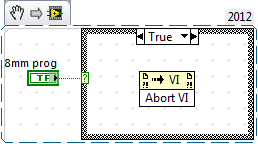

This is my prog

07-12-2013 02:58 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Please show me exactly how can I do it, thanks

07-12-2013

03:07 AM

- last edited on

05-12-2025

09:57 AM

by

![]() Content Cleaner

Content Cleaner

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Sorry to say, but your code is huge and complete mess....

There is no problem writing huge codes, but it should be modular/readable/scalable...

Now I can see there are 3 While loops, what is the loop rate of largest While loop?? This rate will decide, how much duration it will take to stop the VI after you will hit '8mm prog' boolean...!!

you should change the architecture... Producer/Consumer suites your requirement.

07-12-2013 03:44 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

I have a stop button here but it doesn't work, as a green circle

And I did an emergency stop as a red circle is it writhe?

07-12-2013 03:45 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

I mean here

10-02-2019 12:48 PM - edited 10-02-2019 01:08 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

I have a large program operating a manufacturing unit. Besides having a physical emergency stop button I also wanted an emergency stop/reset control on the Labview front panel.

My program has five sensors and twenty controls for pumps, vacuum valves, gas input valves, and ovens. If the operator puts in the wrong input at the start of the program it can be costly.

My programs all start with a flat sequence where all controls are set to a given, safe state. That being said, the emergency stop/reset button can become easy.

The reset button is just placed on the front panel. It is not wired directly to anything. It is monitored by an event structure which is outside of all loops. The event structure does not time out. When the reset button is clicked the event structure is activated. The event will have the first program call up a second program and have it run. The second program will then halt the first program, reset all the controls to default values, then restart the first program and turn itself off.

The idea is simple and versatile. The second program could just pause the first program, take control of the machine to get it in a safe condition, then restart the first program.

Again, this works for me since I do have that initialization structure at the start of my programs. The attached sample programs were written in Labview 2015.

10-02-2019 01:25 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

I have a Labview program running a machine in the factory. It has twenty control lines for gas valves, vacuum valves, turbopumps and movable ovens. In the event of something going wrong there is a physical switch to kill the power. That is a last resort since it can damage the equipment and the turbopumps.

It is important to note that all my programs start with a flat structure which sets all the default values for the controls so that the machine is always in a safe starting mode. It closes all the gas valves, all the vacuum valves, and moves the ovens to an indicated location. That being said, it is easy for me to do a software emergency stop and reset.

Outside of all the loops there is a reset button and an event structure. The reset button is not wired to anything. The event structure does not time out and is solely there to monitor the reset button. When the reset button is clicked then the event structure takes over.

The event structure will call up a second program and get it running. The second program takes over the first program by halting it, resetting the front panel controls to default values, then restarting it. The second program will release the first program then turn itself off. The first program now goes back to its beginning to set the system into its initialized safe state.

The attached photos show a very simplified version of what is done.

10-02-2019 01:36 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Why are you replying to a 6 year old post, and why would you do an Emergency Stop this way?