- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

For loop inside a while loop

Solved!10-03-2011 09:24 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

10-03-2011 09:41 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

10-03-2011 09:56 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

10-03-2011 10:02 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

First, don't maximize the window for the block diagram. Once you have it not maximized simply resize it like you would any other window in Windows. Then simply keep your code within those foundries.

Mark Yedinak

Certified LabVIEW Architect

LabVIEW Champion

"Does anyone know where the love of God goes when the waves turn the minutes to hours?"

Wreck of the Edmund Fitzgerald - Gordon Lightfoot

10-04-2011 06:07 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

You have asked a few questions since I last posted.

To change directions (I presume you mean the stepper motor), you just go thorough the array of steps in the opposite direction. I think that you know that, and that your real question is how to make the program do that. This is one place where a state machine could be very helpful. If you had a Step state and one of its inputs is Direction, then it could either increment or decrement the array index accordingly. I would not make any attempt to figure out how to fix your porgram.

"I tried enclosing the for loop inside a case structure and used a while loop with shift register..." ???? You probably only need the two loops of a Prodcuer/Consumer Architecture. The Producer would have the DAQ Assistants and one or two queues to transfer the data. I cannot tell how much data you get or the relative timing, so it is not clear how many queues are appropriate. No local variables. The Consumer would be the state machine which interprets the data and moves the motor.

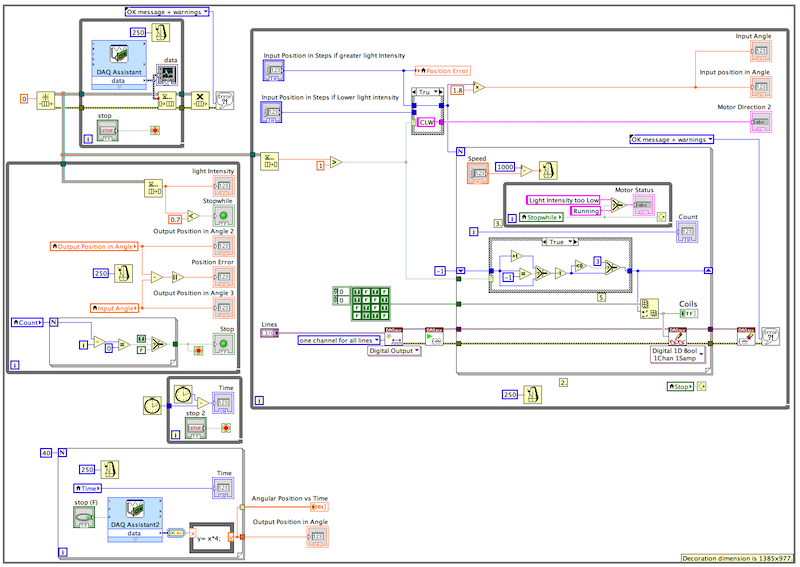

The way I reduced your diagram was by selecting one loop (and sometimes the things connected to it) and then running Clean Up Diagram from the Edit menu. After doing this with each loop separately, I moved the loops closer together and did some manual fine tuning of the diagram layouts. It is better if you never let anything get bigger than the boundaries of your screen whle you are creating the VI. Then you do not need to shrink it. Creating subVIs is also helpful, although they should be created fo some logical, functional purpose, not just to shrink code. For example the code to calculate the motor dorive index and array indexing might make a good subVI. Inputs would be Previous Index and Direction and the output would be the 1D array of booleans that connect to the Digital Write and Coils.

The image is reduced to take up less space on the browser. Actual size of the bounding decoration is 1385x977 pixels.

Lynn

10-07-2011 06:32 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Ok I added state machine to my program as you suggested and created a separate que , now the problem Iam experiencing with this stepper control program is that for loop inside the while loop keeps running infinitely and it should stop once it has reached the given steps or N...which in this case is the input to the for loop N. I dont know how to fix this..

10-07-2011 07:14 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

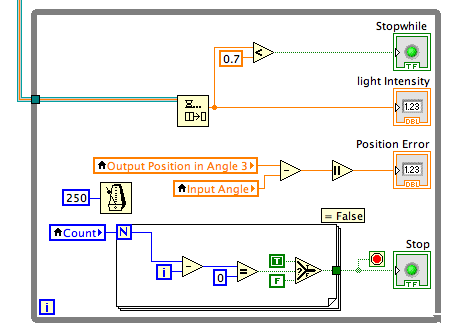

I presume you are talking about this for loop?

Create a little test VI with just the for loop. Replace the local with a control. Put indicators N, i, and the boolean inside the loop. Add a delay inside the loop. Run it.

Hint: "i" starts at zero and increases to N-1.

Lynn

10-07-2011 08:19 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

10-08-2011 02:25 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

I do not understand your question.

The state machine consists of a while loop with a state shift register and a case structure containing three state cases: start, counterclockwise, and clockwise. None of the states has has any kind of infinite loop. The start state has a state selector and writes all coils off to the Digital Output. What do you mean by "condition statement"?

In both the CW and CCW states you go throught that Rube Goldberg modulus count code in one direction or the other and write the step patterns to the Digital Output with 50 ms delay between steps. There is nothing which keeps the for loops from running to N and stopping. About 3.75 seconds in the CCW case and 7.5 seconds in the CW case.

Pressing the stop button (if you can find it on that huge front panel) will not do anything until the current state and probably the next state complete. So it could take 15 seconds to stop if you press the stop button just after it is read at the beginning of a CW state and the next state is also a CW state. Have you waited that long?

Have you run this with Execution highlighting turned on?

Lynn

10-08-2011 07:47 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator