- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Algorithm that can calculate the shortest path between 0-360 degrees for an AC servo motor.

Solved!09-20-2022 06:33 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

I am still trying to wrap my head around it as your (OP) comments are confusing. Can you give a set of values?

Currrent Position(Abs) , Target Position(Abs), Command Position to Servo (Abs)

0, 15, 15

15, .....

Soliton Technologies

New to the forum? Please read community guidelines and how to ask smart questions

Only two ways to appreciate someone who spent their free time to reply/answer your question - give them Kudos or mark their reply as the answer/solution

09-20-2022 08:22 PM - edited 09-20-2022 08:25 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

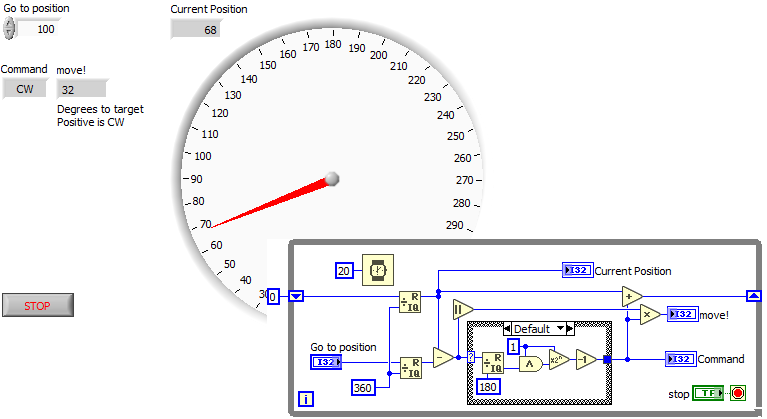

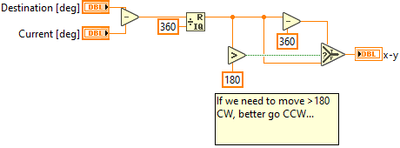

See if this can give you some ideas....

(Of course you can skip the animation and go directly to the "Move!", but then you won't be able to tell what it does.... 😄 Also note that except for the stop condition, there is nothing green at all!)

Try it out....

I am using integers because stepper motors typically have discrete steps. While the angles can be floating points, the rest of the calculations should be done in stepper units. You can easily convert based on steps/revolution.

09-21-2022 02:03 AM - edited 09-21-2022 02:11 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@Jay14159265 wrote:

So now I am confused, if the servo is at 0deg and you want it to go to 270deg do you send it 270 or -90, or something else?

If the engine is at 0 position, if I want it to reach 270 degrees according to the compass logic, -90 degrees should be sent because the shortest path is -90 degrees, but if I send (+270) degrees, it will still go to 270 degrees, but it will have come a long way.

santo_13 wrote:I am still trying to wrap my head around it as your (OP) comments are confusing. Can you give a set of values?

Currrent Position(Abs) , Target Position(Abs), Command Position to Servo (Abs)

0, 15, 15

15, .....

It can move the motor with absolute position in CW or CCW direction. For example, if I send 10, if I write 10 degrees 150 degrees, it goes to 150 degrees using CW direction.

if I type -10 it goes to -10 degrees in CCW direction. If I type -250, it goes to -250 degrees.

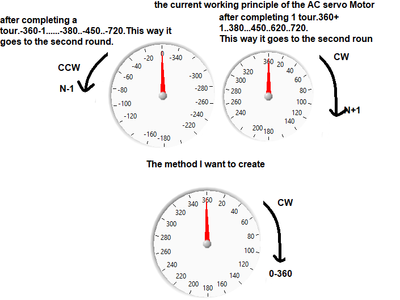

I have given some examples in the picture below, I hope I have been able to explain.

altenbach wrote:

See if this can give you some ideas....

(Of course you can skip the animation and go directly to the "Move!", but then you won't be able to tell what it does.... 🙂

Also note that except for the stop condition, there is nothing green at all!)

Try it out....

I am using integers because stepper motors typically have discrete steps. While the angles can be floating points, the rest of the calculations should be done in stepper units. You can easily convert based on steps/revolution.

My main problem here is if the motor has moved in the CW direction, for example, if it has reached 100 degrees, if I write -100 to the motor again, it will turn to -100 degrees in the CCW direction. That is, it moves with absolute positioning information, not incremental steps like a typical stepper motor.

Thanks for your answers. It's my fault I didn't put the picture description. I think I can explain the situation a little more in the picture above.

09-21-2022 02:07 AM - edited 09-21-2022 02:48 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

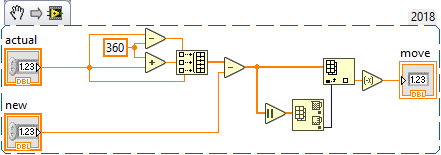

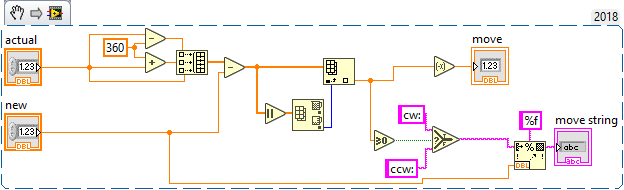

Here is my solution... without bells and whistles

EDIT... didn't read all the new stuff ... missed the part for cw ccw and absolute position .. 😉

so a little addon: cw or ccw needs to be checked 😉 , the actual command needs to be build anyway 🙂

Henrik

LV since v3.1

“ground” is a convenient fantasy

'˙˙˙˙uıɐƃɐ lɐıp puɐ °06 ǝuoɥd ɹnoʎ uɹnʇ ǝsɐǝld 'ʎɹɐuıƃɐɯı sı pǝlɐıp ǝʌɐɥ noʎ ɹǝqɯnu ǝɥʇ'

09-21-2022 02:22 AM - edited 09-21-2022 02:28 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@altenbach wrote:

wiebe@CARYA wrote:

This calculates the difference between the 2 angles, and gives the shortest dAngle to that position.Careful there. The difference can be anywhere between -359 and +359.

You're right, it would require another mod 360 after the subtraction. The first two mod 360's are probably redundant after that.

09-21-2022 03:12 AM - edited 09-21-2022 03:14 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@Henrik_Volkers wrote:

Here is my solution... without bells and whistles

EDIT... didn't read all the new stuff ... missed the part for cw ccw and absolute position .. 😉

so a little addon: cw or ccw needs to be checked 😉 , the actual command needs to be build anyway 🙂

I tested this, but as I explained in the previous message, if -125 is sent to the motor, the motor will start from 0 and go to -125 degrees in the CCW direction, which corresponds to 235 degrees when compared to the compass logic.

No matter how many turns the motor turns, it should go to 235 degrees with compass logic.

According to the current position of the motor, the degree to which the motor should go is 235, but maybe -125 should be sent so that the motor reaches 235 degrees.

Maybe it is 235 degrees for the motor to go, but it is necessary to write 235 for the motor to turn 235 degrees.

maybe the motor should go to 235 degrees, but for the motor to go to 235 degrees, (360+235)595 should be written. It just depends on the current position of the motor (whether it has moved in CCW or CW) and the shortest path.

09-21-2022 04:05 AM - edited 09-21-2022 04:07 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

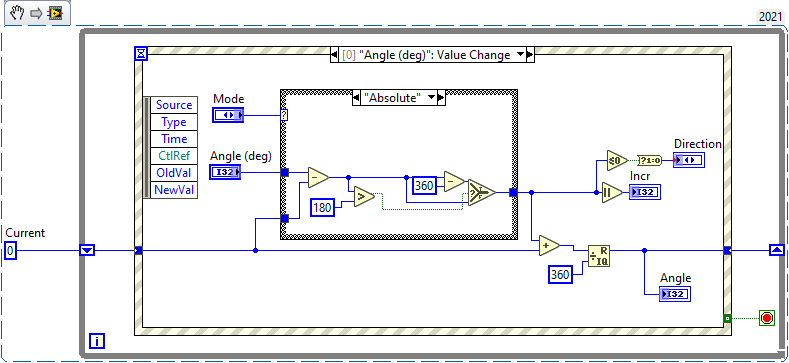

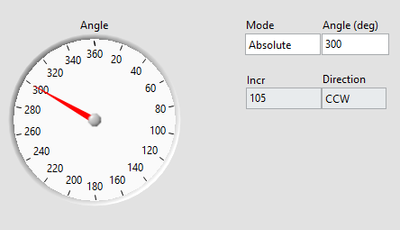

Here's my attempt. The idea is that you just calculate the increment between the current and new angle, going CCW if the difference is >180. You can select relative or absolute angle. (LV2016 vi attached).

This way you can write CurrentAngle+Increment to your stepper motor.

09-21-2022 05:00 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@Basjong53 wrote:

Here's my attempt. The idea is that you just calculate the increment between the current and new angle, going CCW if the difference is >180. You can select relative or absolute angle. (LV2016 vi attached).

This way you can write CurrentAngle+Increment to your stepper motor.

Thanks for your effort.

Here, as in previous posts, there is an issue with incremental positioning. So there is no absolute position that we can send directly to the motor. Whereas the motor must go to an absolute position.

09-21-2022 06:21 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

It's still not clear to me what you mean by the absolute position of the motor. Is this position restricted to 0-360? Or can it go beyond?

When you start the motor and the software, the angle is 0. If you just store all the increments of my example, you know the position of the motor. Let's say you move 200 degrees, 3 times, that's 600 degrees. Is it sufficient to send 600 to the motor?

09-21-2022 06:32 AM - edited 09-21-2022 06:39 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Well, I thought for a minute I had managed to decipher what the request was, but apparently not. Let me try to restate my present best guess:

It sounds like the motor controller is a little bit stupid and has a faulty method for travelling to the requested destination. It *will* arrive at the correct absolute angle that you requested, but it may take the long way around to get there. So you want to intervene and (sometimes) add or subtract 360 from the target position, forcing the stupid controller to take the shorter path.

If I understand right, the controller's problem is that it uses the sign of the commanded position to determine which direction to travel. The table below lays out what I'm supposing your controller would want to do, and how you would want to intervene to do a smarter thing.

| Start Pos | Original Cmd Pos | Controller Motion | Modified Cmd Pos | Controller Motion |

| 330 | 30 | CW 60 deg | 30 | CW 60 deg |

| 30 | 300 | CW 270 deg | -60 | CCW 90 deg |

| 300 | -30 | CCW 330 deg | 330 | CW 30 deg |

| 330 | 240 | CW 270 deg | -120 | CCW 90 deg |

| 240 | -60 | CCW 300 deg | 300 | CW 60 deg |

| 300 | -180 | CCW 120 deg | -180 | CCW 120 deg |

If this is an incorrect understanding, please lay out a similar sequence of commanded positions to help define:

A. Which direction and how far the motor would move if you didn't modify the command

B. How you *want* the motor to move instead

C. What command position you would need to send to make the motor move the way you want

And please don't use examples where the motor starts from 0 position! It becomes ambiguous whether your subsequent talk about degrees refer to a *position* or a *relative distance*. Also, please make a special effort to be really clear about whether you are describing what DOES happen vs. what you WANT to happen. As I read back through the thread, I often found it hard to tell b/c different msgs seemed to contradict one another. Probably some were describing what DOES happen while others were describing what you WANT, but I'm not entirely sure which is which.

-Kevin P