- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

Mobile Monitoring and Control of a Small Hydro Power Plant

Contact Information

University of Ljubljana

Faculty of Mechanical Engineering

Control, manufacturing System and Computer Technology Laboratory – LAKOS

Askerceva 6, SI-1000 Ljubljana

Team Members | Faculty Advisor(s) |

Luka Selak | Professor Alojz Sluga |

Aljosa Pockaj (Aljoša Počkaj) | Dr. Gorazd Hlebanja |

Matjaz Kosir (Matjaž Košir) |

|

Jernej Habe |

|

Klemen Povsic (Klemen Povšič) |

|

Primary Email Address: gorazd.hlebanja@fs.uni-lj.si/luka.selak@gmail.com

Primary Telephone Number +386 1 4771 746/ +386 31 865 120

Project Information

List all parts (hardware, software, etc.) you used to design and complete your project:

Software tools for the MOSPP

- LabView 8.5, Professional Development System (Web Publishing Tool, SQL Toolkit for LabVIEW, serial interface, application builder )

- Mysql (data management)

- Visual studio web developer (web interface for database)

- Netbeans (Java embedded system for Siemens TC65)

- Additional development tools (ProE, Eagle, CamBam)

Hardware

- Daq card Ni - USB 6009

- Stepper motor controller Geckodrive 203V

- Stepper motor Nanotec ST5918S3008-L

- UPS

- Cinterion - Siemens SMS module MC35it

- Cinterion - Siemens TC65 with Java

- Electric energy meter: MT375

- USB GPRS/UMTS modem ZTE in Hyundai MB-810

- Angle measurement RLS: sensor chip AM8192B1

- Inductive switch for the rotational frequency measurement

- Temperature measurement: sensor chip MCP9700

Describe the challenge your project is trying to solve.

Approximately 500 small hydro power-plants are operational in Slovenia, most of them ranging from 25 to 100 kW. They provide about 12% energy of renewable sources. Most of them have been built in 90-ties by private land owners due to legislation encouraging them through subventions and bounties. Most of them have been initially implemented with manual controls only. Since they are located in remote or even inaccessible areas there is no evidence of their state, no alarm in case of malfunction.

Quantity of water, which can be used in a power-plant, is, besides actual flow, temperatures, season, etc., governed by ecological considerations and jurisdiction. Thus it is necessary to observe and to collect corresponding values. A historical overview of such information aids in planning electrical energy supply to the grid and can help to clarify circumstances of ecological events.

However, the introduction of new information and communication technologies offers new possibilities of effective operation control and monitoring. They became less expensive and more reliable and thus interesting for proprietors and operators of such power-plants. Whereas control and monitoring systems of big power-plants are sophisticated and expensive, the need for low cost solution is apparent.

The basic aim of this project is therefore a remote monitoring and control of a small hydro power-plant enabling safe stop, activation, and deflector manipulation, alarming critical events and data logging of important parameters.

Describe how you addressed the challenge through your project.

The basic influencing factors in design, construction and operation of power-plants are water regimes, environment protection and the available technology at the time of construction. Consequently, power-plants differ regarding turbine type, deflector or guide vanes actuation, available water volume, allowable maximal and minimal head, safety technology, automatic activation, etc.

An operator visually inspects dam water level, produced electric power, bearings temperature, vibrations, and acts upon discovered faults in a manually controlled power-plant. He also controls and manipulates guide vanes according to a head, produced energy and other instructions, e.g. assurance of a biologically minimal flow of water. Whenever the power-plant cutout of a grid happens the operator should revisit and activate it; meanwhile the plant is out of operation for several hours. Information about generator run out, excess or shortage of water in a dam is critical. Cabling to a remote site can be very expensive; radio wireless communication could be obstructed by a terrain configuration. A classical internet requires a phone connection and a corresponding web access.

A system for monitoring and control of a small hydro power-plant (MOSPP) communicates with an operator through a mobile network due to its high signal coverage, high flexibility and no infrastructure costs. A DAQ module, consists of sensors measuring relevant power-plant parameters, conditioning and data acquisition hardware. The computer based supervision is built in parallel to the existing one and should enable necessary control functions. The easiest way of run away or run down detection and notification is by measuring generator RPMs and transmitting alarming SMS. The basic structure of the MOSPP consists of the DAQ module, a managing interface (computer and software) and a user interface. The managing interface treats signals, logs them and represents them graphically, either locally or remotely. The operator manages the power-plant based on critical event or according to his judgment. A command is sent from a remote computer to the managing interface through the DAQ and relay unit to a switching interface.

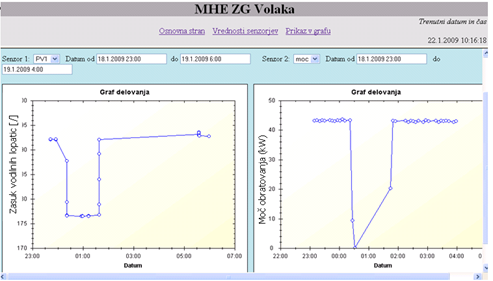

Data stored in the data base enable graphical representation of operation history, documentation of events, etc.

Sensors should be insensitive to the environmental circumstances (temperature, humidity, etc.). Semiconductor based temperature, vibration, pressure, and angular position sensors with analog output have been selected. And robust sensor housings adapted to them were produced.

Measured produced energy power is the basic information on power-plant operation, implying water level and flow and certain events, e.g. obturation by leaves. Power readings are acquired from the existing digital meter in the interval of five minutes. The meter is acting as an instrument and can be accessed by its commands. The Acquired data are logged which enables elaboration of daily and monthly reports, statements of account, invoices to the customers, etc.

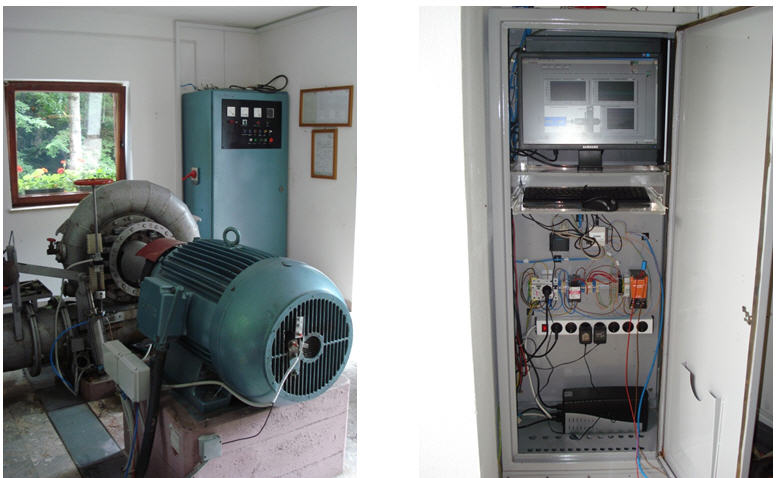

Fig. 1: Generator and Francis turbine Fig. 2: Control center

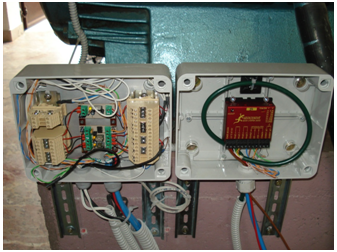

DAQ and data logging are performed by National Instruments equipment. A low cost NI USB-6009 is the selected hardware for signal acquisition, digital I/O and stepper motor actuation. LabView development environment including Database Connectivity Toolkit has been employed to build an application for monitoring, data logging and controlling actions of the MOSPP. Monitored data trigger alarm in case of exceeding any limit values. Such event is e.g. critically low water level.

Data logging stores data in a MySQL data base. To prevent excessive data flow only data changed for values exceeding certain limit are stored. Such a datum element is a dam water level or head. The mobile networking is still slower in comparison to broadband connection, thus the said data flow reduction is convenient.

The power-plant historical data are accessible by a web interface. A remotely located operator connects to the managing interface through the internet and makes inquiries on particular data stored in the data base. The data is not duplicated in this way. The data base serves as a source in composition of operation reports, reporting non-operating time, sudden run downs, etc.

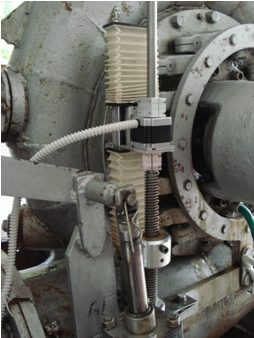

The power-plant can be directly controlled in the engine house through its switching interface. If one wants to stop the plant, he/she pushes the stop button. After a fault has been repaired the start button should be pressed to activate the power-plant. The remote control is assured by an additional relay unit, which triggers the appropriate button. The relay unit is controlled by NI USB-6009 digital outputs. The guide vanes angular position can be as well corrected remotely. This is achieved by a stepper motor powered ball spindle. The motor itself is powered by a Gecko drive and control pulses are generated by the NI USB-6009. The rest of DIOs is used to monitor some control panel indicators.

The mobile network crucial advantage lies in its ubiquitous signal. Business users are entitled to business data transmission with a safe private mobile IP network. Inside such private network communication between any particular SIM card is possible anytime anywhere. An APN (access point number) and a password are assigned to the user, and each SIM card obtains its own IP address. The data transmission speed is comparable to that of the classical modem connection and is sufficient for the MOSPP. The response (PING) between SIM cards is usually less than a second.

The working prototype of our remote control and monitoring system has been implemented in the small hydro power-plant “Volaka”, Fig. 1, having a Francis type turbine, with a nominal power of 70 kW, water flow of 250 l/s, head of 38 m and inlet pipe of 500 m. whereas Fig. 3 illustrates the MOSPP. The control center photographed in Fig. 2 includes the computer, its monitor and its UPS, a DAQ card NI USB 6009, and power supplies for a stepper motor and a private mobile network modem.

Fig. 4: Signal conditioning and stepper motor drive

Fig. 5: Guide vanes actuation device

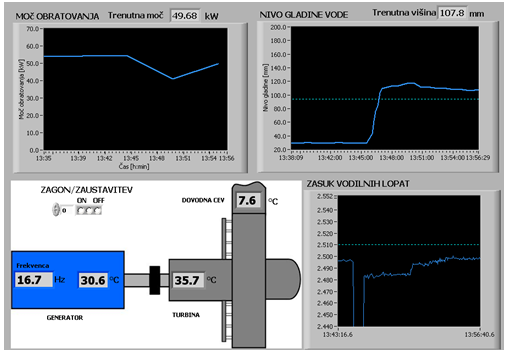

Fig. 6: GUI of the MOSPP: Generator – turbine arrangement with some temperature

indicators (bottom left; Power-time diagram (top left); dam water level (top right);

guide vanes angular position (bottom right)

Fig. 7: Remote representation of historical data

Some advantages of the MOSPP can be summarized as follows:

- Estimation of the monthly contribution due to the use of the MOSPP is 5%.

- Additional sensors improve the insight into the power-plant, which makes its maintenance easier.

- The remote monitoring and control facilitate operator’s work conditions.

- Better control of water flow through prompt water level observation and remote control of guide vanes according to a head, produced energy and other instructions, like biologically minimal water flow in the stream.

- Moderate pricing and security of the private supervisory mobile network.

- Flexible MOSPP design makes adaption of the system easier.

- The VI based GUI enables easy insight into the power-plant state

- Error messaging system is automatic and prompt.

- Data base offers numerous reporting possibilities and automated invoicing

The overall expense of this particular solution is estimated at 4.000 €. Monthly subscription to a mobile private network currently amounts to 20 €.