- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

mySmartAircraft: Stress-Free Flight Boarding

mySmartAircraft: Stress-Free Flight Boarding

The worst part of boarding a busy flight is often the stress-filled trek... up & down the aisles... as you desperately try to find storage for your carry-on luggage!! The overhead baggage compartments are a free-for-all space, available on a first-come, first-served basis - and can ignite anxiety and territorial disputes as passengers frantically shuffle, stack and squeeze their precious belongings into any available space.

What if... the moment you board the aircraft, you knew exactly where storage space was available, saving your time and nerves. Sounds incredible? This could be a reality with my baggage compartment sensor system that provides real-time feedback on the amount of empty space in baggage compartments throughout the plane, even if the hatches have been closed. The visual indicators transition from green to amber to orange to red, as each compartment fills.

Although its a minor improvement to the overall aircraft structure, it provides low-cost solution to improve boarding time and passenger experience, and reduce the operating cost for airlines.

About the Developer:

My name is Ruta Marcinkeviciute and I am studying Aerospace Engineering at The University of Manchester. I am currently doing an Industrial Placement at National Instruments. Working in various different societies such as Flight Simulation society which are available in this University, I have developed a passion for finding ways to positively influence the Aerospace Industry. Through the easy of use of National Instruments tools and over a course of 1 week I was able to complete a proof of concept system which I believe could change the way you board the aircraft!

About the Project

The System Summary:

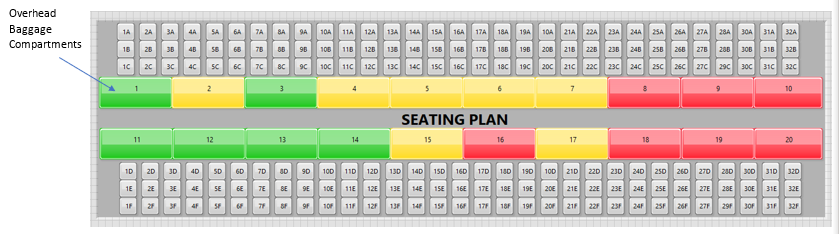

MySmartAircraft consists of two major parts, a sensor system and two user interface elements - (1) LEDs on each compartment and (2) dashboard/display that visualises the storage status of the entire plane. Aircraft seating plan dashboard/display (2) could be shown at the aircraft entrance (as passangers board), on mobile devices on the aircraft attendants, or even on "inflight entertainment" screens. This display not only includes seat numbers but also the plan of overhead baggage compartments, colur-coded to indicate their state (how full they are) (See below).

This allows boarding passengers/attendants to check what are the nearest available baggage compartments to their seats. Following that, when the passengers start moving through the aisle, they are presented with LED indicators on each baggage compartment displaying the same information as in the dashboard (GREEN/YELLOW/RED). This way, by allowing easy navigation inside the aircraft, this system reduces congestion and discomfort caused by people walking up and down the aisle trying to find a space in the overhead compartments.

Hardware and software design:

Project hardware is comprised of four main components: sensors, LED indicator, myRIO controller and a display. The 4 infrared proximity sensors inside the baggage compartment sense the distance to the nearest object. They are configured with an initial distance to walls of an empty compartment. This initial empty state is indicated with GREEN colour of an LED as well as on the seating plan display (Fig. 1). When an object is placed inside the box, the sensors sense that the distance has now changed and is shorter and the indicators turn to YELLOW. If at least one sensor senses a change – the colour changes from GREEN. If the compartment is sufficiently full – in other words, if at least two sensors measure the predefined smallest allowable distance, the state becomes RED.

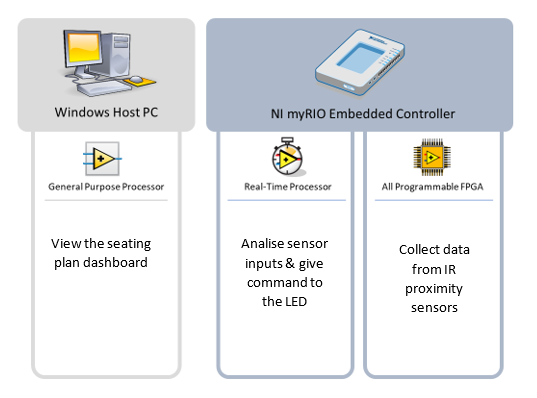

Data acquisition and analysis is done in myRIO using myRIO functions. They are easy to use and allow vast variety of applications since you can easily program your code to communicate with the FPGA, where data acquisition is done, and then process the data on the Real-Time target.

Here's a demonstration to show the functionality of one compartment

TIP: Keep an eye on the LED attached to the right-hand side of the mock-up compartment...

Hardware:

- myRIO

- RGB LED – current sinking circuit set up.

- 4 x Sharp Infrared Proximity Sensor (GP2Y0A21YK0F)

- Breadboard and Veroboard

Software:

How to use the code:

- Open the project and run the Sensors System VI

- After 3 seconds the Range indicators should become active and settle to original values. These values indicate the range to an empty compartment walls.

- Confirm that the Compartment 1 indicator and box LED light up Green.

- Put a small box in the box and observe the indicators from above go Yellow.

- Put some more objects in the box or hold one closer to the sensors and confirm that the indicators' colour changes to Red.

- Remove objects from the box and observe the indicators changing to Yellow and then returning to Green.

The Future

At the moment this project can work with one overhead baggage compartment. Next step would be to scale this to address all the compartments in the aircraft. Here are some details on what is yet to come for this project:

Features to add:

- To make the boarding experience even more smooth – the following additional feature could be added: after scanning your ticket at the aircraft door, the display could show for 3-5 seconds the compartment number which is the most suitable for the passenger (the closest available baggage compartment for the seat number).

- Add running average functionality to level out the measurements and reduce sensibility to outside turbulence.

- Add colour intensity feature to indicate how much the compartments is filled.

- Instead of colour coding the state of the compartment – show icons of objects that can still fit in. For example, if there is still a lot of space left – show a hand luggage icon. Similarly, if the is very limited space left – show a handbag/folded coat/hat.

- Integrate LabVIEW WebServices for the application to be controllable remotely via Wi-Fi.

Programming:

- Make the code more scalable to easily add control for more compartments – convert the current MainVI to a subVI which would acquire data from all the compartments and analyse it to display on a common display.

- Make a stand-alone application to function without a computer.