- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

Telemetry System for Solar Car

by

Neo Wei Ren

School of Mechanical Engineering Undergraduate

Nanyang Technological University

Singapore

Products Used:

NI cRIO-9014 Real-Time Controller

NI cRIO-9104 8-Slot, 3M Gate CompactRIO Reconfigurable Embedded Chassis

SEA cRIO-GPS+ module

NI 9870 module

NI 9401 module

NI 9219 module

NI 9211 module

LabVIEW 8.6.1 FPGA Module

NI Serial 3.4

NI VISA 4.4.1

The Challenge:

To develop a low-power Real-Time monitoring system for a solar car taking part in the World Solar Challenge covering 3000km from Darwin to Adelaide, Australia. The aim is to be able to monitor the health of the vehicle and be able to optimize our race strategy without having to stop the vehicle.

The Solution:

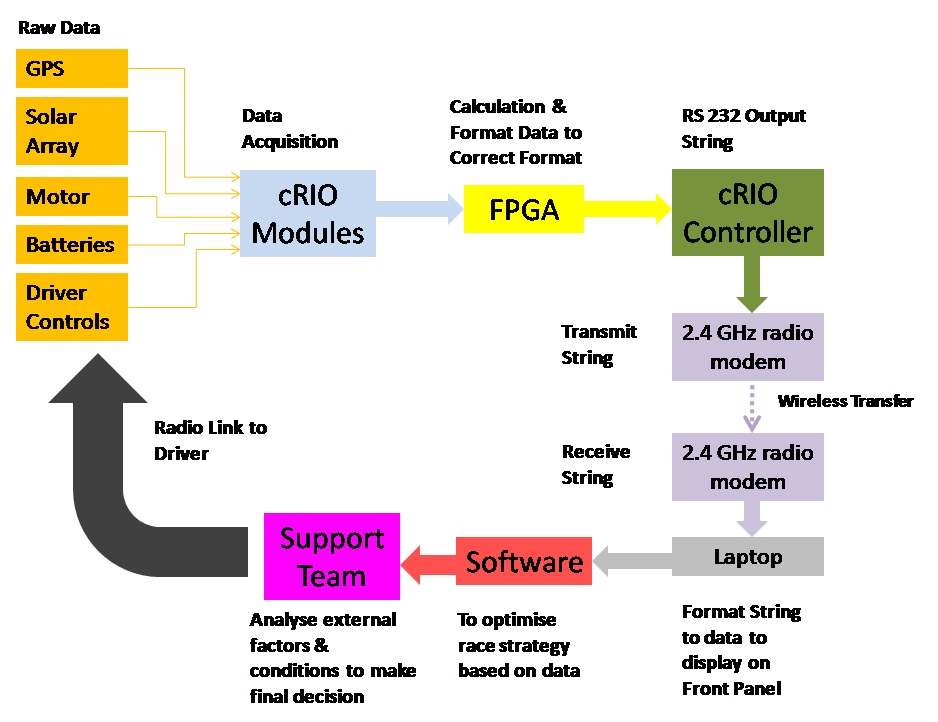

NI CompactRIO controller and chassis with 8 modules were used to monitor the voltages, currents, temperatures and speed of the vehicle. This information would be transmitted wirelessly using a 2.4 GHz modem to a chase vehicle following the solar car.

Abstract

The World Solar Challenge is a bi-annual competition that allows universities from around the world to design and build a fully solar-powered vehicle that can travel 3000km across Australia at an average speed of over 80 km/h. The aim of this competition is to promote research into sustainable transport. Key areas of interest are aerodynamics, solar conversion ratio, battery technology, low rolling resistance tyres and electric hub motors. A well thought out race strategy is also pivotal to whether the solar can survive the full distance of the journey across Australian terrain.

Purpose of Telemetry

The World Solar Challenge is different from other solar car competitions as it requires the team to travel 3000km from Darwin to Adelaide, Australia. This sheer distance to be travelled in the race means that every minute problem that may surface along the way could determine whether the solar car can complete the journey. Using NI CompactRIO and with its configurable chassis and LabVIEW software, a telemetry system can be developed for the solar car to monitor, log and transmit the data reflecting the real-time health of the solar cells and the batteries (Diagram 1). These real-time data not only allows the support team to come up with an optimized race strategy, it also reduces the troubleshooting time as the monitored data would trigger alarms such that we can prevent any problems even before they arise. The actions performed by the driver can also be monitored and logged to perform post-race analysis.

Diagram 1: Using CompactRIO during testing of our solar vehicle

Our Focus

Our solar car has a multitude of mechanical and electronic data to be collected and analyzed, but our main focus is on the electronics side of the vehicle as it would be the determining factor for completion of the race. Data collected from the battery and solar cells is used in the design process to determine the sizing of the battery and to come up with the performance curves. Real-time data collected during out road runs have allowed us to optimize the performance of the vehicle and to compare how far the actual specifications of the car differ from the design specifications. Our race strategy team will also make use of the data collected to calculate the optimum speed to travel with reference to weather forecasts. All the data can be logged in the CompactRIO built in memory for post race analysis to improve on future projects.

Using CompactRIO with Reconfigurable Chassis

CompactRIO was chosen because it combines real-time data acquisition on customizable input channels and the ability to both record and transmit these data. The 8 module chassis allows us to choose the types of modules to cater to our unique needs so that we can focus on what we want to monitor. A wide range of modules available for selection lets us change our chassis as we move along the project as we focus on different aspects of our solar car. The onboard memory and multiple I/O types on the cRIO-9014 controller allow flexibility in the choice of interface and secondary data storage.

Our customized chassis includes a SEA cRIO-GPS+ module to provide a real-time position tracking of our vehicle, a NI 9870 module to capture data from out battery monitoring system which has a RS232 interface, a NI 9401 digital I/O module to capture vehicle speed from the motor controller terminals and output of data, four NI 9219 analog I/O modules for monitoring of throttle, brakes, currents and voltages of the solar array, and a NI 9211 thermocouple module for sensing of temperatures around the vehicle. The use of NI 9219 universal analog I/O modules allows us to monitor multiple data types including voltages, currents, temperature and resistance, with high accuracy and resolution.

LabVIEW FPGA

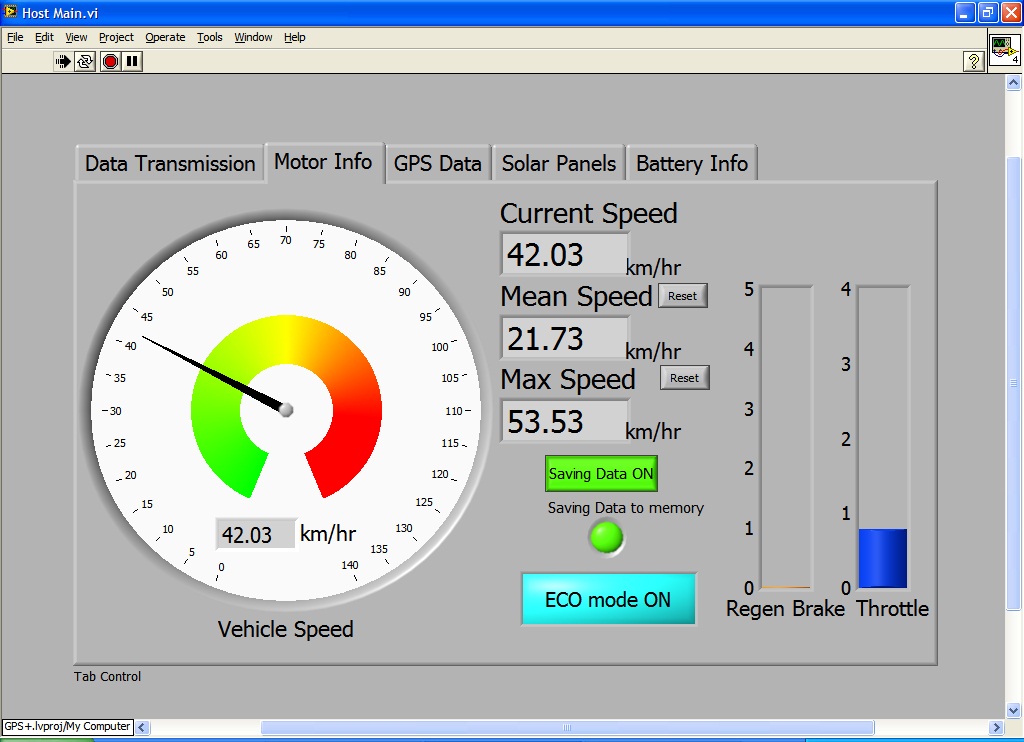

Using LabVIEW FPGA programming is fast and easy to grasp as it is graphical and the express VIs provide shortcuts for the user to quickly change the program to suit their needs. It even allows us to run our program on startup of the CompactRIO, which makes the whole system wireless as I do not need to connect to the system to manually start the program prior to the race. Coming from a mechanical engineering background, we have limited programming experience but the intuitive graphical icons and wires that resemble a flowchart makes programming fast and fun for an amateur. The FPGA programming mode allows us to integrate all 8 modules as not all the modules can be used in SCAN mode. All the collected data can be viewed real-time in the chase car and optimize our race strategy according to a program we have formulated (Diagram 2).

Diagram 3: Real Time Data as Seen on Chase Car

Our Application

In the design phase of the project, the CompactRIO was used to record the performance of the solar cells so we can come up with the performance curve of the cells in different weather conditions. The batteries were also hooked up with the system to find out their discharge curves at different temperatures. The actions of each driver was monitored for each test runs to whether they are doing the right things as they are alone in the cockpit and the support team cannot physically see what they are doing.

Due to that fact that we are being powered solely by the sun, we have to try our best to minimize the use of power in our electronics and direct the main bulk of power to the motor as the primary objective is to cross the finishing line 3000 kilometres away. The customized 8-module chassis would capture data such as GPS location, battery information, solar cell condition, motor performance and the driver actions. All these data will be recorded in the 2 GB onboard memory in the cRIO-9014 Real Time Controller. At the same time, the same data will be formatted to a text string using VIs in LabVIEW and sent using a low-power 2.4GHz radio modem to a chase vehicle behind the solar car (Diagram 3). This provides a redundancy of information storage as the data will be stored both in the Real Time Controller and laptop in the chase car. At the chase car, the race strategy team will analyze the collected data and decide the speed to travel at with reference to external factors such as road, driver and weather conditions.

Diagram 3: Block Diagram of Our Telemetry System

After each road test, the data will be analyzed and fine-tuning will be done to the mechanical components of the car such as adjusting the wheel camber, steering sensitivity, suspension and tyre pressure to improve the performance of the solar car. LabVIEW also allows us to simulate the different weather conditions that we may encounter in Australia so as to have a better idea of what level of power our solar array can provide. Post race analysis will also be conducted using the recorded data so that improvements be made to future solar cars.

Conclusion

Since this is the first time that we are using a real-time monitoring system for our solar car projects, we were initially unsure of what will be our main focus due to the fact that there are simply too many areas in a solar car that we can acquire data from be it digital or analog. As our team went along the project, we figured that we would use the CompactRIO not only for the actual race but also in the design phase of the project. It was used to chart the battery discharge rates at various temperatures and to find out the performance of our home-made solar array. Not only can it let us remotely monitor multiple channels of data, the CompactRIO also allows us to log the data in its onboard memory to carry out post race analysis. Its 8-module customizable chassis has given us a lot more time to really decide the main focus of our system and lets us change the modules to cater to our unique needs. It has benefitted our team in all phases of our project, from design to the actual race to post race analysis. As this is the first of many solar projects to come, cost can be saved by using the same chassis and controller, and either using the same modules that our team used that this team used or by simple changing some modules for a different focus. The CompactRIO is truly fantastic system to consider for any team pioneering any projects.