- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

NI Compact RIO for Real-Time Energy and Information Management of the PV-H2 Research Vessel Solgenia

Contact Information

| University: | Konstanz University of Applied Sciences, Germany |

| Department: | Electrical Engineering and Information Technology |

| Team Members: | Various Bachelor and Master students |

| Faculty Advisors: | Prof. Dr-Ing. Richard Leiner |

| Primary Email Address: | leiner@htwg-konstanz.de |

| Primary Telephone Number: | +49 (0)7531 206244 |

Project Information

Project Title

NI Compact RIO for Real-Time Energy and Information Management of the PV-H2 Research Vessel Solgenia

Parts List

The whole energy and information management system is build on NI LabVIEW, NI Compact RIO and a NI Touchpanel PC.

| Software | Hardware | Hardware Description |

|---|---|---|

| NI LabVIEW | NI cRIO-9004 | Embedded real-time controller, 195 MHz Pentium-class processor, 64 MB DRAM |

| NI LabVIEW Real-Time Module | NI cRIO-9104 | 8-slot, 3M gate reconfigurable embedded chassis |

| NI LabVIEW FPGA Module | NI 9853 | Highspeed CAN-Module, up to 1 Mbit/s |

| NI LabVIEW Touchpanel Module | NI 9401 | 8-channel, 100 ns ultrahigh-speed, 5 V/TTL, sinking/sourcing digital I/O |

| NI 9203 | 8-Ch ±20 mA, 200 kS/s, 16-Bit Analog Current Input Module | |

| NI 9201 | 8-Ch, ±10 V, 500 kS/s, 12-Bit Analog Input Module | |

| NI 9411 | 6-Channel, 500 ns, ±5 to 24 V Digital Input Module | |

| NI 9265 | 4-Channel, 100 kS/s, 16-Bit, 0 to 20 mA Analog Output | |

| SEA Gxxxplus | GPS, GSM, GPSIB, EDGE Combo Module (www.sea-gmbh.com) | |

| NI PPC-2015 | 2.0 GHz Pentium 4 processor, 512 MB RAM, Touchpanel PC |

Challenge

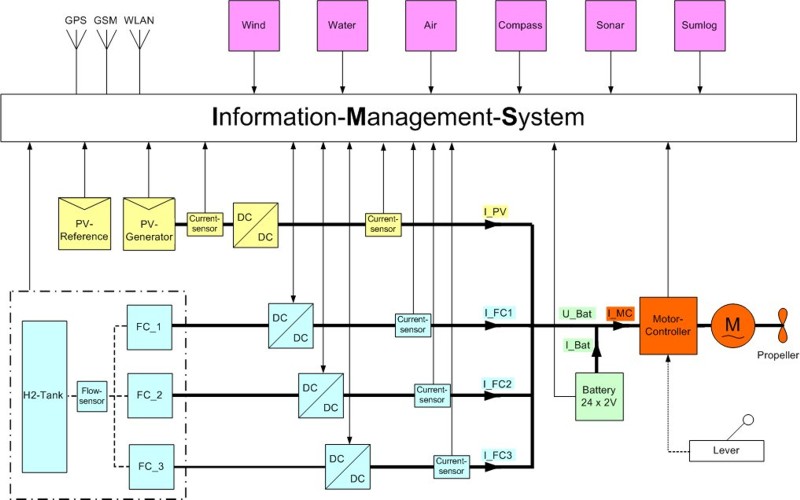

Since solar radiation as a primary energy source underlies statistical variations as function of time, 100% of energy supply at any time cannot be guaranteed. For a professional operation of vessels the combination with a secondary energy source therefore is necessary. One of the most convenient options for use within the mobility sector is hydrogen from renewable energy sources. The energy supply system consists of two energy conversion units (PV-generator and fuel cell) and two energy storage units (battery and hydrogen tank). A DC/AC-inverter together with an asynchronous motor converts the electrical energy into mechanical energy for the propeller. The voltages between the three fuel cell modules as well as the PV-generator and the battery are adjusted by DC/DC-converters. The hydrogen will be provided by an electrolysis unit within the laboratory driven by a PV-generator.

One of the research aims is to adapt the hydrogen production to hydrogen demand by the stationary and the mobile fuel cells: another task for energy management.

Solution

Energy management

The energy management is the main task of the board computer. One of the research aims is to develop and optimize the management rules. The energy system itself consists of one controllable (fuel cell) and one not controllable energy converter (PV-generator) as well as of two energy storage devices (battery and H2-tank). So an energy management in a very simple way is possible. This is important, since the Solgenia additionally will be used as laboratory unit in teaching: The students shall become familiar with the fundamental problems of managing renewable energies.

Figure 1: System Overview

Information management system

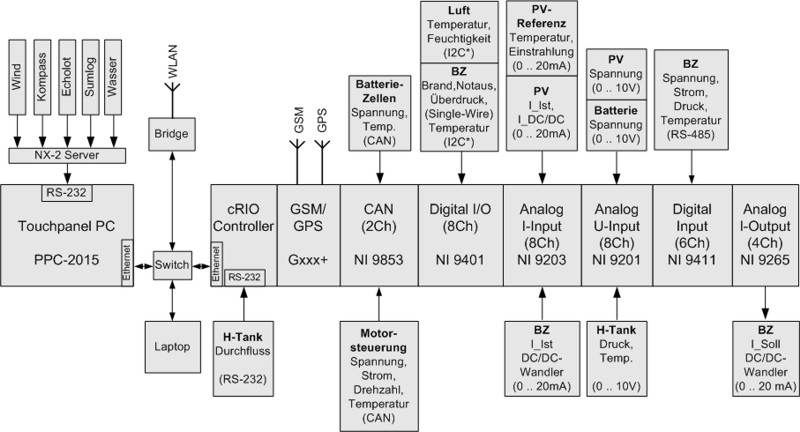

The requirements for an Information Management System (IMS) are complex and diverse. On one hand it has to offer a real-time control and measurement architecture and on the other it needs to allow for a human machine interface (HMI) as well as communication and data logging of mission critical process data to a remote server system (e.g. to optimize and adapt the hydrogen production). Using the internet and standard communication methods like LAN/Wi-Fi or GSM are most convenient as they are widely available, low cost and proven.

The IMS has to read and display all sensor information available throughout the entire system. In case of the Solgenia, more than 90 parameters are handled for the energy and information system. Most common parameters are temperature, flow rate and current generated by the fuel cells, voltage, current and charge of batteries and water depth, course and speed of the vessel.

Due to the different nature in sensor and actor signals and a variety in communication and interface (RS232, CAN, NMEA, Current In/Out, Voltage In, GPS, GSM, Ethernet) requirements drove the decision to base the system on NI LabVIEW and NI Compact RIO. Further supporting factors were number of certifications and standards NI Compact RIO was meeting, the limited space on board the vessel and graphical programming language that could be used to program the embedded controller as well as the touchpanel PC-based HMI.

Figure 2: Embedded Archtitecture

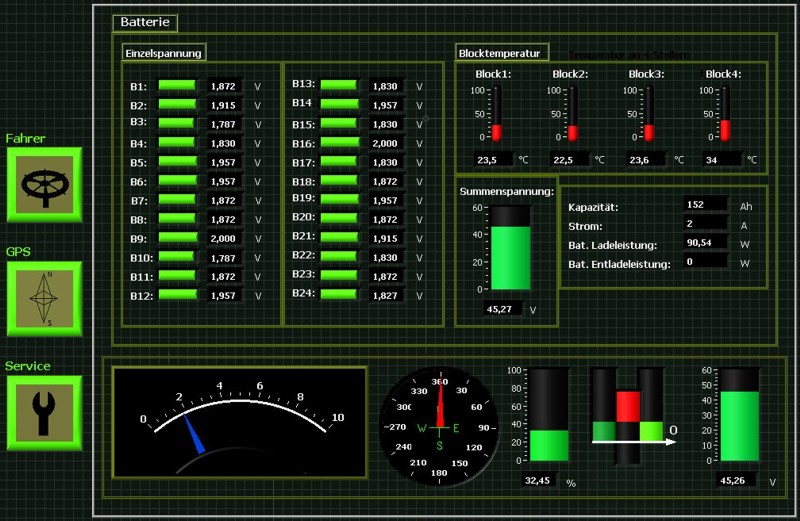

The human machine interface used the full power of NI LabVIEW's frontpanel capabilities. It not only displays the process data for the steerman in a way typical for nautical vessels but it also features a password protected data portal for the researcher showing detailed data for fuel cells, batteries and the photovoltaic array.

Figure 3: HMI used by a steerman

Figure 4: HMI used by a researcher

Figure 5: PV-H2 Research Vessel Solgenia

Please insert video below:

Ingo Foldvari

Area Sales Manager - US West Academic

National Instruments