ni.com is currently undergoing scheduled maintenance.

Some services may be unavailable at this time. Please contact us for help or try again later.

- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

Video showing actual performance of Experiment

Contact Information

University: College Of Engineering, Pune

Team Members: Rohan A.Paranjpe,

Anjali A. Patil,

Rajesh S. Kaje,

Prashik D. Khadse

Faculty Advisors: Prof. P.R. Dhamangaonkar

Email Address: rohan30802010@gmail.com,

Project Information

Title: Design and Development of Virtual Set-up To Determine Dryness Fraction Of Steam

Description:

Virtual labs are a fusion ofcreative engineering and objective conceptualization techniques to yield aninteractive experience. It is a set of teaching and learning tools designed toenhance a student's learning experience. Computer animation and visualizationcan help to illustrate complex physical phenomena easily. Furthermore, theygive us additional insight into problems during classroom teaching as well as in the individual study process.

Products: LabVIEW 8.6

The Challenge:

Determination of dryness fraction of steam can be done with the help of various calorimeters. Types of calorimeters are asfollows:

- Separating calorimeter

- Throttling calorimeter

- Separating and throttling calorimeter

For calculating dryness fraction ofsteam by separating calorimeter, mass of condensate collected and mass of steam condensate are required. This data can be obtained by taking pressure of steamand quantity of sample steam as input.

Calculation of dryness fraction of steamby throttling calorimeter, pressure of steam and temperature after throttlingsteam are taken as input.

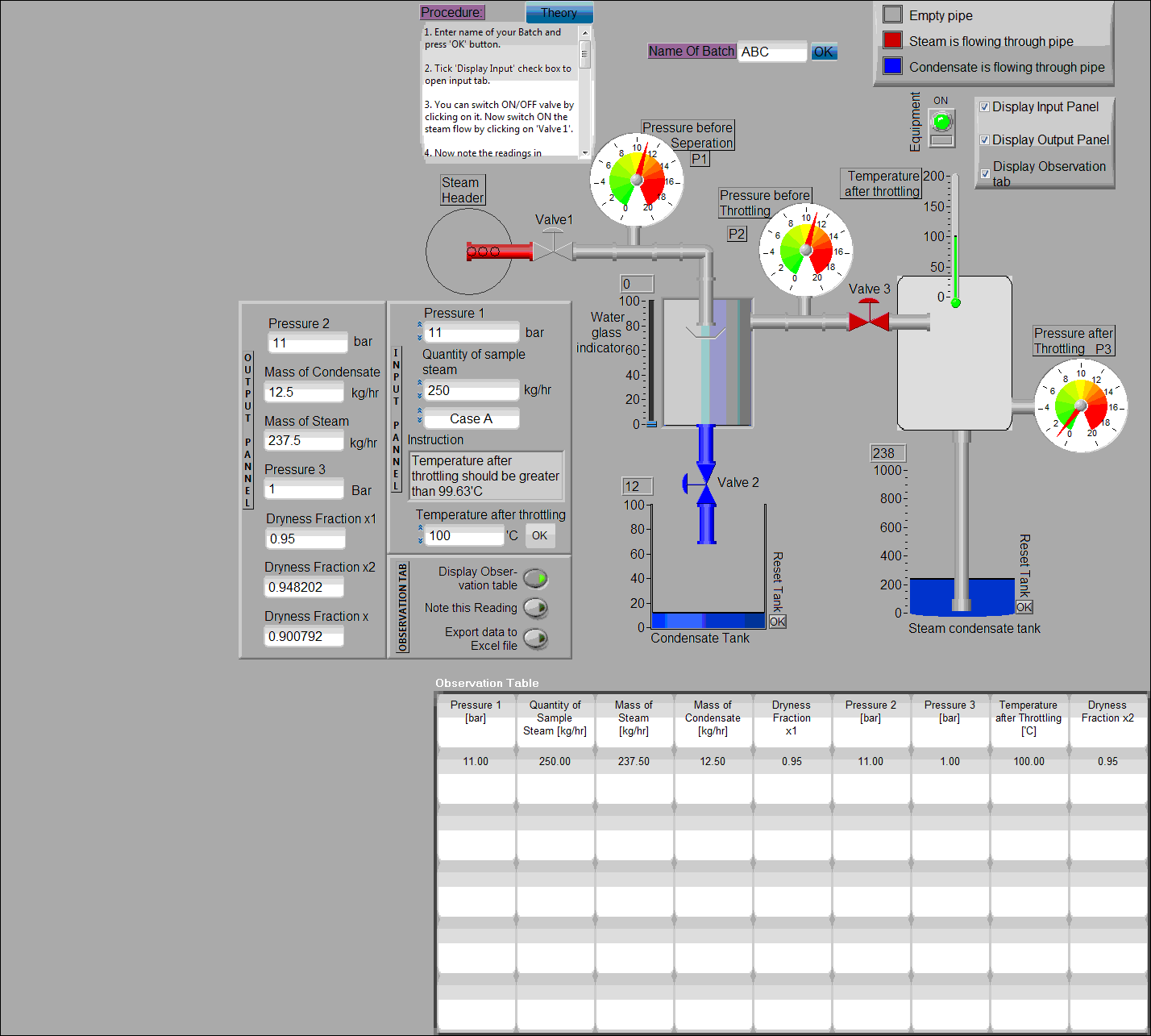

For calculating dryness fraction ofsteam by separating and throttling calorimeter, pressure of inlet steam (p1)from steam header, quantity of sample steam and temperature after throttlingare required. Pressure of steam after separation (p2),mass of condensate and mass of steam, pressure after throttling (p3)are calculated prior to the calculation of dryness fraction. In this process,two values of dryness fraction are calculated by considering separateassemblies as separating and throttling calorimeters. Final dryness fractioncan be calculated by taking product of two dryness fractions obtainedpreviously.

The Solution:

The development of VIs for calorimeters, use of flat sequence structure is used along with flat sequence which allowed getting complete input data from user firstly, and then doing the further calculations. Local variables were used to make available data in the next sequence or to note the change in condition in thefollowed sequence. Animation were used for maintaining the proximity of virtual lab to the real laboratory experiments. Animation included the representation of steam flow after separation or throttling. This was achieved by making specially customized indicators, with the help of LabVIEW as well as Macromedia flashcreator. Filling or emptying of the tanks was done by use of specially arranged sequential functions. Hence it was mandatory to use functions like ‘select’,‘or’, ‘increment’, ‘equal to’, ‘not’, ‘decrement’, shift register, for loop and while loop. Property nodes were also used for sequential displaying of all parameters on front panel in desired order. Outputs were represented in observation table on front panel, standard table was used. While loop is used for sequential data entry in the table. All the data was converted from numeric form to fractional string and given to observation table. Data from observation table was made available to user in excel sheet. For doing this write to spreadsheet file function was used. To facilitate the performance and use of setup, instructions are also provided in procedure window. User can access detailed instructions by open a separate VI on click of THEORY button. This was achieved by use of property nodes and invokes nodes. For continuous execution this process was achieved by use of while loop. The VI property was changed to run on start for execution of VI as soon as it is opened. This avoided the need of providing separate start button on front panel.

Use of LabVIEW extensively helped to make possible to develop this virtual set-up of Experiment to determine dryness fraction of steam.

Figure: Experimental set-up as seen on front pannel

Open the files named 'Separating Calorimeter Experiment', 'Throttling Calorimeter Experiment' or 'Separating & Throttling Calorimeter Experiment' for the experimental Set up.

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Hi,

Thank you so much for your project submission into the NI LabVIEW Student Design Competition. It's great to see your enthusiasm for NI LabVIEW! Make sure you share your project URL with your peers and faculty so you can collect votes for your project and win. Collecting the most "likes" gives you the opportunity to win cash prizes for your project submission. If you or your friends have any questions about how to go about "voting" for your project, tell them to read this brief document (https://forums.ni.com/t5/Student-Projects/How-to-Vote-for-LabVIEW-Student-Design-Projects-doc/ta-p/3...).

I'm curious to know, what's your favorite part about using LabVIEW and how did you hear about the competition?

Good Luck, Liz in Austin, TX.