- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- « Previous

- Next »

Starting user programming on a work related project

01-04-2017 11:26 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@RTSLVU wrote:

Our main products are UPS's for the telecomunications industry and inverters for alternative energy.

Our production ATE does not require high speed DAQ so we base our ATE stations around the Keysite 34970A/2A DAQ/Switch unit I mentioned before.

Sounds like what I WAS used to. I was testing RF boards on ATE stations using Keysight as well. This is a different realm that I am having trouble understanding lol

01-05-2017 09:52 AM - edited 01-05-2017 09:53 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

The worlds aren't that different. It just seems so because you're getting acclimated to the new one while also being asked to do something that many of us struggle to understand. You'll notice the only point made in this conversation that would lead towards the motivation is price. I asked about it as a side point and another user brought it up as a likely motivation. But, it makes less sense to me if you're trying to use the station you currently have to be more flexible. You've already invested in the most expensive parts of the PXI. The work to get your system to be more flexible is using different DAQ cards in the chassis. Unless you're trying to duplicate the system, I don't see where you'd get any better cost.

Let's look at the problem from a different direction. Mentally replace the PXI with the Keysight equipment you're used to. If the manager asked you to find a solution that removed the Keysight component, what questions would you ask? Those are the kinds of questions you really need an answer in order to move forward in a way that'll make your manager happy. If his goal is to swap out pieces, even if they're just connectors, so that you can use the same hardware to test multiple DUTs on site, you might be able to perform that with the hardware you already have on hand. If his concern was cost while gaining the flexibility, you'd be a hero by solving it without adding any additional hardware costs. If you'd need to add hardware, you'd want to know what adding a card to the PXI would cost versus creating a new hardware solution so you can compare the two effectively.

In my time with NI, I've received a lot of "How do I do x?" questions. For the most part, they can be easy to answer. But, I'm not really doing the person a favor by answering those questions. There's generally a motivating reason I'm being asked for the way to do x. But, doing that isn't always the best thing. It might be, and replacing the PXI with another hardware option might be best for you now. You'll have better success at making the manager happy if you understand WHY he wants to do what he wants to do. He's trying to solve some sort of problem. His best perceived solution is to replace the PXI. Is that the best way to handle the problem or is that just one possible solution? If it is, by all means push forward. But, it's hard for anyone (including you) to help with your manager's task without understanding what the actual problem is. When you can define that, it'll make the conversation here as well as the one with your colleague have far more meaning. Right now, most of the conversation is speculation as to what the problem your manager is solving really is.

01-06-2017 09:01 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi Everyone!

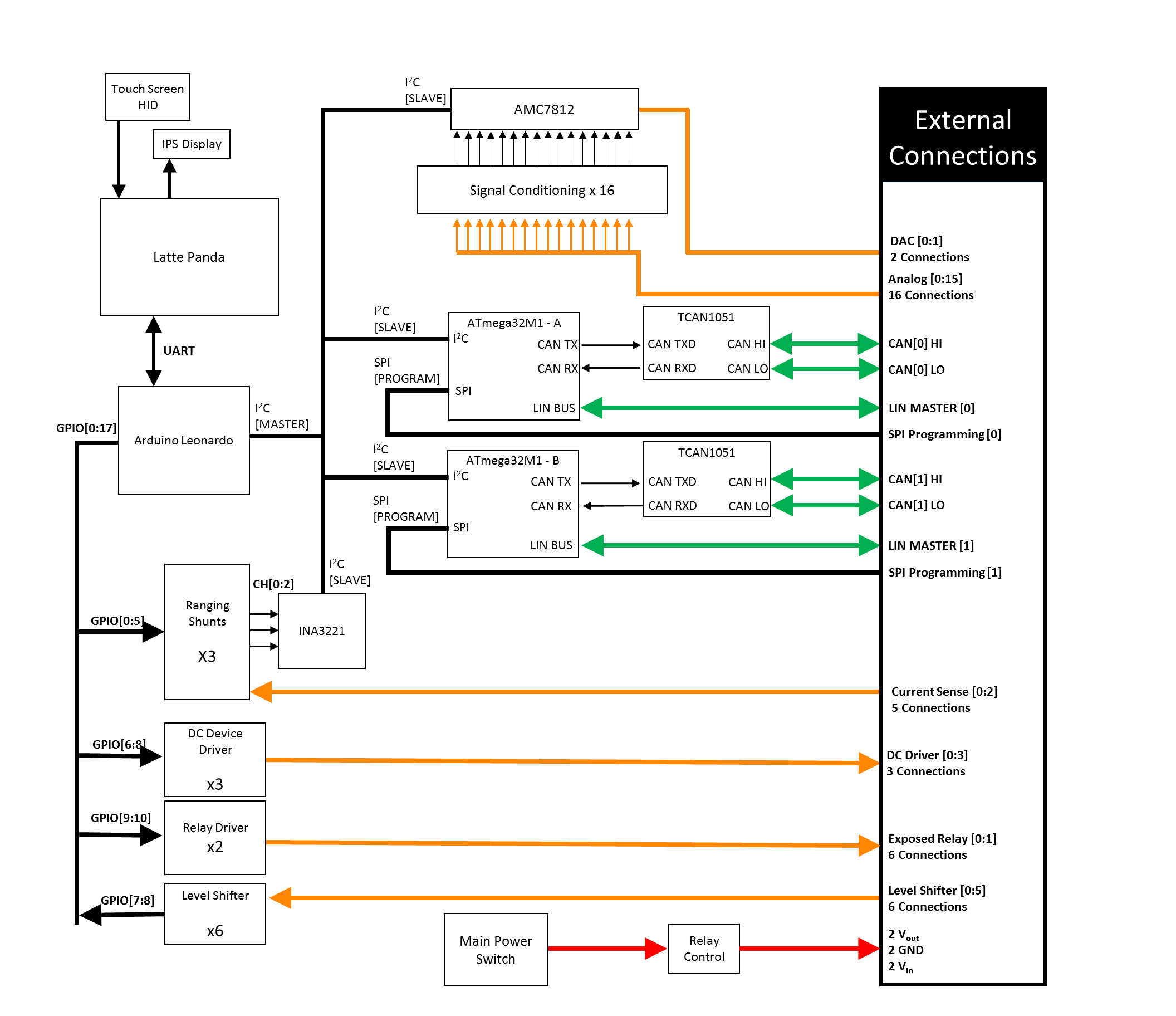

Okay so over the past couple of days and conversations with different people in my group, I have come to a few conclusions. My first question regarding the replacement of the current PXI systems that are being used has been answered! A little more detail on the project, we are using a LattePanda to power a custom PCB that has the functionality that the PXI system does. Below is a block diagram of the PCB architecture.

I hope this gives everyone a better understanding of the backbone of the project. This device will have capabilities to handle Analog, LIN, CAN, and Digital communication. From this point I must develop code to test functionality only. This is much easier than I thought, but I am still new to LV and have little knowledge on where to start. Imagine a switch, say a 4 button configuration on the overhead compartment of your vehicle. Below is a list of functions that the switch would perform (Can't give too much detail, it's confidential).

|

Table 10 : OHC Function list |

|||

|

# |

Function |

NOTE |

|

|

1 |

switch_OPEN_RSW |

Rear sliding window |

|

|

2 |

Switch_Close_RSW |

Rear sliding window |

|

|

3 |

switch_OPEN&CLOSE_RSW_backlighting_led |

Rear sliding window |

|

|

4 |

switch_Tilt_VT |

vent |

|

|

5 |

Switch_down_VT |

vent |

|

|

6 |

switch_tilt&down_vt_backlighting_led |

vent |

|

|

7 |

switch_OPEN_SS |

Sunshade |

|

|

8 |

switch_Close_SS |

Sunshade |

|

|

9 |

switch_ open&close_SS_backlighting_led |

Sunshade |

|

|

10 |

switch_OPEN_SR |

Sunroof |

|

|

11 |

switch_Close_SR |

Sunroof |

|

|

12 |

switch_ open&close_Sr_backlighting_led |

Sunroof |

|

This function's list would be the main testing that would need to be incorporated into this device. With simple voltage and sleep current as well.

Given that this is just one switch produced here, the long term goal is to be able to functionally test every smart switch that we produce. This device should cost no more than $300 per device to manufacture, where our current final testers run around $25,000. The numbers are what is the motivation for my boss to get this working. I think that from this point the most help I will need is in the development of the LV software because he wants it to "look pretty" and that I know, is the difficult part of the development. I am not ready to begin the software development but I am eagerly reasearching the best approach to the start of the development. I will follow up this post with more detail about some of the requirements that are needed.

Thank you for your input everyone!

Dennis

01-06-2017 10:56 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Good work!

I think we should be able to close this thread since your original Q was answered and you now have the big pciture.

To proceed from here I would suggest you "devide and conquer" breaking the porject down into parts that are as simple as possible. If you get stuck on any of the simple stasks, start a new thread to focus on the issue you encounter.

Once you get a single simple part covered, take shot at waht seems to be the most ocmplicated part. Again ask if you need advice.

Then before diving in and trying to integrate the simple and the hard, take time to step back and look at the big picture to make sure you do not run into problems when it comes time to tie it all togeteher. When path looks clear, "plan your and then work your plan".

And do not forget to have fun as you grow in "the way of wires" !

Ben

01-06-2017 10:59 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@Ben wrote:

Good work!

I think we should be able to close this thread since your original Q was answered and you now have the big pciture.

To proceed from here I would suggest you "devide and conquer" breaking the porject down into parts that are as simple as possible. If you get stuck on any of the simple stasks, start a new thread to focus on the issue you encounter.

Once you get a single simple part covered, take shot at waht seems to be the most ocmplicated part. Again ask if you need advice.

Then before diving in and trying to integrate the simple and the hard, take time to step back and look at the big picture to make sure you do not run into problems when it comes time to tie it all togeteher. When path looks clear, "plan your and then work your plan".

And do not forget to have fun as you grow in "the way of wires" !

Ben

Ben,

Thank you for the honest and straightforward adivce! And yes I will surely start a new thread when I am ready to begin the next phase!

Dennis

- « Previous

- Next »