Contact Information

University and Department: Penn State, Department of Bioengineering

Team Members: JJ Dienno, Kristina Snyder, Brittany Flaherty, Anna Han, Michael Navitsky, Tony Ligouri

Primary Email Address: kas651@psu.edu

Project Information

Describe the challenge your project is trying to solve.

People in third world countries, like Kenya and Tanzania, have little access to health care. This lack of health care is not because these people do not care about their wellbeing; rather, the problem arises from the large lack of doctors and nurses and the expense to travel to a clinic. For every 50,000 people in Kenya, there is only 1 physician. On the other hand, in America, for every 300 people there is one doctor.

Heart Disease was the eighth leading cause of death in Africa in 2000.

The World Health Organization estimates that heart disease can be responsible for 361,000 deaths in Africa and projects that this number will double in magnitude by the year 2030.

Importance of Blood Pressure Measurement...

- Research has shown that high blood pressure is the most common risk factor for heart disease and stroke.

- High blood pressure can seriously damage the kidney and can worsen atherosclerosis by allowing for the thickening of the blood vessel walls.

- The problem with this condition is that it usually has no symptoms, in fact, high blood pressure has gained the nickname the "silent killer" because of this characteristic and many people live with the condition without knowing it and without treatment.

- Thankfully a simply blood pressure reading can be performed on people to determine whether they have a blood pressure related disease and whether they are at a major risk for other diseases or conditions; and with the proper exercise, diet and medicine the condition can be controlled relatively easily.

The two numbers in a blood pressure measurement represent systolic and diastolic blood pressures. Normal human blood pressure hovers around 120/80. The systolic blood pressure value, 120, represents the arterial peak pressure, and the diastolic blood pressure value, 80, represents the minimum arterial pressure.

Images courtesy of www.cardiosmart.org

These pressure readings serve as a scale in determining levels of blood pressure disease. The British Hypertension Society defines high blood pressure as well as other blood pressure states with the chart seen below.

Describe how you addressed the challenge through your project.

Material Components:

The pressure cuff was created in response to the design constraint of using readily available materials. Due to the vast use of bicycles in Africa, it seemed reasonable to use a material for the cuff which could be obtained from spare parts. The inner tube tire was a perfect fit due to the fact that our pressure cuff would need to be inflated to a relatively high pressure to seal off the blood vessel.

The initial prototype pressure cuff was created from a strip of the inner tube tire which was slightly over a foot long. The ends at each side of the tube were sealed using a strong epoxy so that the tube would be leak proof. This strip contained the valve through which air is passed by the pump. We next added an additional valve, this time with the plunger removed, through which air would flow freely through to the pressure sensor. The pressure through this tube would be the same as the pressure inside the inflated cuff

Problems with this design: Upon further design consideration, we realized that this type of design would prove to be impractical because of the way that our cuff would deform. Upon inflation, the elastic properties of the isobutyl rubber would cause the cuff to expand away from the body rather than onto the blood vessel. This would make correlation between the pressure in the cuff and the pressure experienced by the blood vessel difficult. Without this information, it would be very difficult to accurately define a patient’s blood pressure.In response to this setback, we decided to modify our design slightly.

Description of Prototype II:

In essence, the design of the third prototype incorporated a majority of the same properties associated with the second prototype. The cuffs were constructed of several sizes in order to fit both a child and an adult. A clasp created from braided wire and wrapped with either electric or duct tape was attached to the end just past the inlet valve. Along the upper length of the cuff, a strip of velcro has been applied. On the opposite end, an additional length of rubber is attached to the cuff. Attached to this length of rubber, the complimentary section of velcro is applied. The cuff now resembles the design of industry produced cuffs. The end of the cuff (far from the inlet) loops through the clasp and then doubles over itself and attaches onto the cuff(by velcro). A major hurdle encountered with all designs has been to contain the seal on the ends when high internal pressures are applied. In the third prototype design we have gone to great lengths to ensure that an adequate seal has been applied. A wide variety of sealants and epoxies have been employed. Currently we have employed the use of a very strong super glue which binds the rubber together very strongly and prevents leakage. The origional epoxy used in previous prototypes is beaded around the outter edges to give an additional level of sealant.

Benefits with this Design:

The main benefit of this design has been it's ability to hold a seal with high internal pressures. The design has attempted to divert pressures from the problomatic end sections. Additionally, with the implementation of the new clasp/ velcro system, the cuff has remained attached to the patients arm.

Final Improvement:

A strip of denem two times the width of the cuff and slightly longer is layered over the cuff. This strip velcros around the arm in an attempt to prevent expansion away from the body. This strip of denim is attached directly to the cuff and the inlet valve extrudes through the denim layer so that pressure may be applied. The prototype no longer utilizes the clasp and velcro system described above. The latching mechanism is now totally controlled externally on the denim layer. The release of pressure from the cuff has proved to be too rapid for accurate signal detection. The method of adding an additional inlet valve, with additional rubber strip with small puncture has been explored. This method has proven to provide for a much slower release rate. Calibration data has not been formatted for this design component however it is believed that more accurate results will be obtained.

This page provides a detailed description of the conceptual elements of the LabVIEW VI design. A detailed description of the actual LabVIEW VI can be found here.

Initial Concept Testing

Using the voltage-to-pressure conversion provided by the sensor spec sheet, the LabVIEW VI was run on ten volunteers from the class. Results were compared to the readings from a digital blood pressure monitor (A&D Digital Blood Pressure Meter Model UA-731), which was also verified using an analog pressure gauge (Marshalltown model 80892). However, the noise was too great to determine the desired peak values for systolic and diastolic blood pressure consistently and obtain a suitable conversion factor. These testing results did prove useful, though, because it was established from waveforms that the systolic and diastolic pressure values corresponded with certain peaks using the peak detection tool in LabVIEW.

Because these values were automatically detected, the VI was redesigned so that the user would not need to listen for the Korotkoff sounds and interact with the program more than the one time he or she would press the start button to run it. A lowpass filter which passes only those frequencies under a typical heartbeat frequency (1-1.67 Hz) was also incorporated in order to reduce the noise. From the testing results, the systolic pressure value appeared as the peak value after the first large drop in pressure. This made sense because between the highest pressure the cuff to which the cuff is inflated and the first Korotkoff sound, there would be no oscillations and thus, no peaks detected as the pressure was released from the cuff. The diastolic pressure value appeared as the peak value before the final large drop in pressure; again, this made sense because after the fifth Korotkoff sound, oscillations are no longer detected, and thus there are no additional great pressure peaks. However, it was soon evident that this diastolic pressure value was only obtained this way because a commercial monitor, which automatically deflated itself after diastolic pressure was determined, had been used. When a commercial cuff and a manual hand pump were used, the diastolic pressure peak was not able to be found.

Figure 1. Waveform when using commercial blood pressure cuff.

This led to a reconsideration of blood pressure measurement and a redesign of the LabVIEW VI to find the systolic blood pressure still using the pressure sensor but

calculating for the diastolic pressure using a known relationship between systolic and diastolic blood pressure and the mean arterial pressure (MAP). Using a bandpass filter to detect only the pulse oscillations, testing was done using a commercial cuff (CVS model CVSBPAUTO (#271245)) to determine the relationship between MAP and the maximum value indicated by the oscillation output from LabVIEW. This linear relationship (see

calibration page) was then included in the LabVIEW VI and used to solve for the diastolic blood pressure.

Figure 2. Waveform showing beginning of blood flow back into brachial artery.

Figure 3. Waveform of oscillations (output from bandpass filter)

The cuff was designed using many materials which will be readily available to the Kenyan people.

Individual cuff components included denim(from an old pair of blue jeans), the inner tube tire from a mountain bike, hollow black cable, a hollow plastic tubing material, Velcro, and super glue. The cuff was created by cutting the inner tube tire into desired section lengths to fit various sized people. The portion of the cuff included the inlet air valve. Each of the ends were sealed with super glue and put under the large pressure of a vice to ensure a proper seal. Next, a layer of denim from an old pair of blue jeans (twice the width of the cuff) is layered over the tubing. This denim layer prevents the cuff from expanding outwards and allows for increased pressure within the cuff. Finally alternate strips of Velcro are attached to the denim so that the cuff may be strapped around the arm in a similar manner to any other pressure cuff you have ever used. The element of the cuff which is attached to our pressure sensor is made from a small diameter, hollow black cable and hollow plastic tubing materials. When heated, the plastic contracts and seals around the cable. An “o-ring” is then place on this end to further ensure proper sealant. The other end of the plastic tubing is sealed using an epoxy to form an airtight seal with the pressure cuff. This plastic pouch is placed under the cuff when recording measurements to record pressure changes with time. Associated costs (United States / Readily available in Kenya)

- Velcro ( approximately 0.1 Us dollars/ max required 10 inches vs. possibly readily available)

- Hollow cable (approximately 5 US dollars for 5 yards, reduces to approximately .33 US dollars per cuff vs. possibly readily available)

- Plastic tubing ( less than 0.01 US dollars for required 2 inch section/ not a significant cost consideration)

- Super glue (1.55 US dollars for 1 oz tube, many pressure cuffs can be created from one tube)

- Blue Jean Denim (recycled from old pairs of blue jeans- zero cost)

- Inner Tube tire (approximately 5 US dollars if purchased new vs. readily available/free in Kenya)

- Pressure Sensor: (8.85 US dollars when purchased in bulk. The sensor will make up the only significant cost component of the project.)

Final Design Overview:

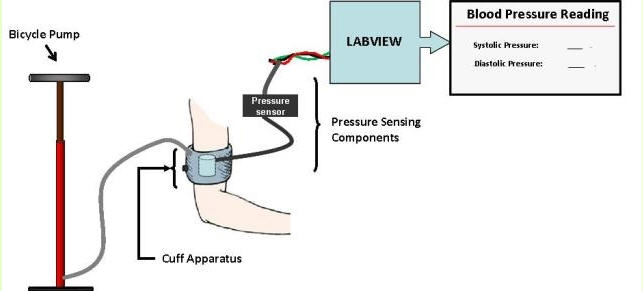

A bicycle pump inflates an elastic cuff made from bicycle tire tubing.

Blood flow through the arm is constricted.

The force from the cuff is transferred to the pressure sensor.

Changes in oscillating waveforms representing blood pressure values are detected by LabVIEW.