- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Need help making a Torque Curve

12-16-2011 03:28 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

I am looking to make a torque curve. I've taken a look at the curve fitting VIs but some of this info flew over my head.

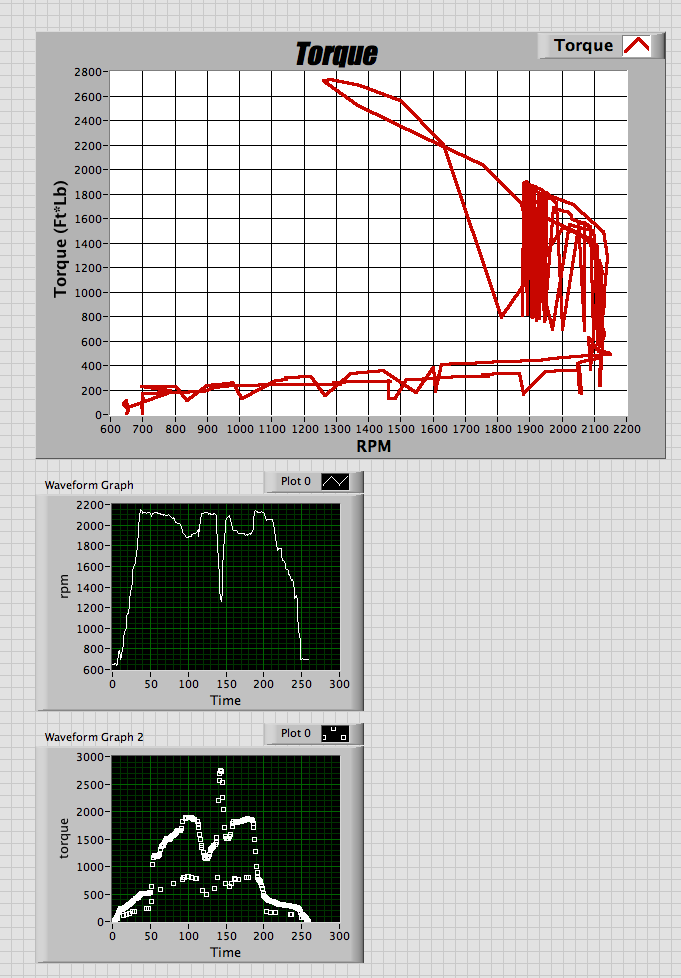

I've attached a simple VI with Torque (Y-Axis) / RPM (X-Axis) data, to where I am making a simple graph. Though, it is a bit complicated to get a good read off of this graph and am wanting to get a smoother graph/chart that shows a smooth torque curve.

Any suggestions on how I would do this?

Thanks.

12-16-2011 03:57 PM - edited 12-16-2011 03:58 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Why do you want curve fitting? Do you have an equation or formula which describes your data?

Have you looked at the data???? Plot the rpm data and the torque data against time (? at least array index). The rpm data ramps up quickly, levels off, has a big dip, then ramps down. The torque data has a huge amount of noise. Starting at index 99 in the torque array you have: 811, 1895, 816, 1898, 1899, ... Actually it probably is not noise so much as something in your system changing gain or impedance abruptly. When you choose a plot style which displays only the points and no connecting lines, it appears that the "upper" and "lower" data track fairly well. It is interesting that there are no "lower" points during the speed dip.

What are you really trying to do with this data?

Lynn

12-16-2011 04:23 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

See the 1st JPG ... In LV I formed an array of particular RPM points I searched, and returned the max torque values at those RPM points. I was trying to accomplish the blue line (mock drawing) that you see in the "Torque Curve" JPG, so as to be able to create a line of the max torque points at particular RPM points. Though, what I am running into is that our test is erratic and there are many similar RPM points where the torque is very low, so the graph does not portrary all that well. I am looking to in a way create a slope for the graph, that begins at the peak Torque point, and the low torque point.

Any ideas?

Also, see the attached VI with how I used the Power Fit curve ... its close but it doesn't necessarily plot exactly on the peak torque points.

12-16-2011 05:11 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

That curve does not look much like a power law curve. Also the control you have marked Order is connected to an input to the Power Fit.vi called Tolerance. Order is a parameter of Polynomial Fit.vi.

I tried using the Array Max & Min fucntion on small subsets of the torque data to find an "envelope" of the data. It smooths things quite a bit. I still could not get anything I thought looked like a good fit. Power Fit was really bad. Polynomial fit was not too good, but much better than Power Fit. Polynomial order needed to be <=4, which is typical for polynomial fits.

Lynn

12-19-2011 07:17 AM - edited 12-19-2011 07:18 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

jonathanupr,

It looks like you are trying to generate a speed-torque curve for a motor. This is created by running through breakdown to locked rotor and then back to full speed in a very controlled manner. I'm guessing that you're using some sort of dynamometer. Am I right so far?

12-19-2011 10:09 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Yes we are using a dynamometer application on a motor. We are running an open-loop system right now, and I am trying to find a way to calculate somewhat of a torque curve with the data from the open loop system. If we used a closed loop system with a control profile we definitely could get a torque fairly easily.

I was thinking of something like this to calculate a torque curve:

Data Point 1: Peak Torque @ RPM

Data Point 2: Torque @ Peak RPM

Data Points 3 to 10: Take an RPM range per each point and find the Max Torque to RPM ratio for each range and display the RPM/Torque index on the graph for this individual point. (RPM range could consist of say 2100 to 2000).

Any other ideas?

12-19-2011 10:14 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

I don't think you can generate an accurate torque speed curve in open loop. The problem is what happens as the motor goes through breakdown. Human hand just can't react fast enough. You also have the issue of inertia which will skew things as well.

What type of brake does your dyne use?

12-19-2011 11:26 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

We are using a friction brake. You are probably right that we can't do an accurate curve in open loop mode. Just trying to get a rough work around.

See the attached JPG... this came out OK but I could use a bit more smoothing to it.

12-19-2011 12:16 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Open loop control will work fine if you don't go through breakdown and make sure you have achieved a steady state before recording data point. How many samples are you averaging at each data point?