- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Measuring current on a Voltage Rail > 10V

Solved!03-20-2014 10:15 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

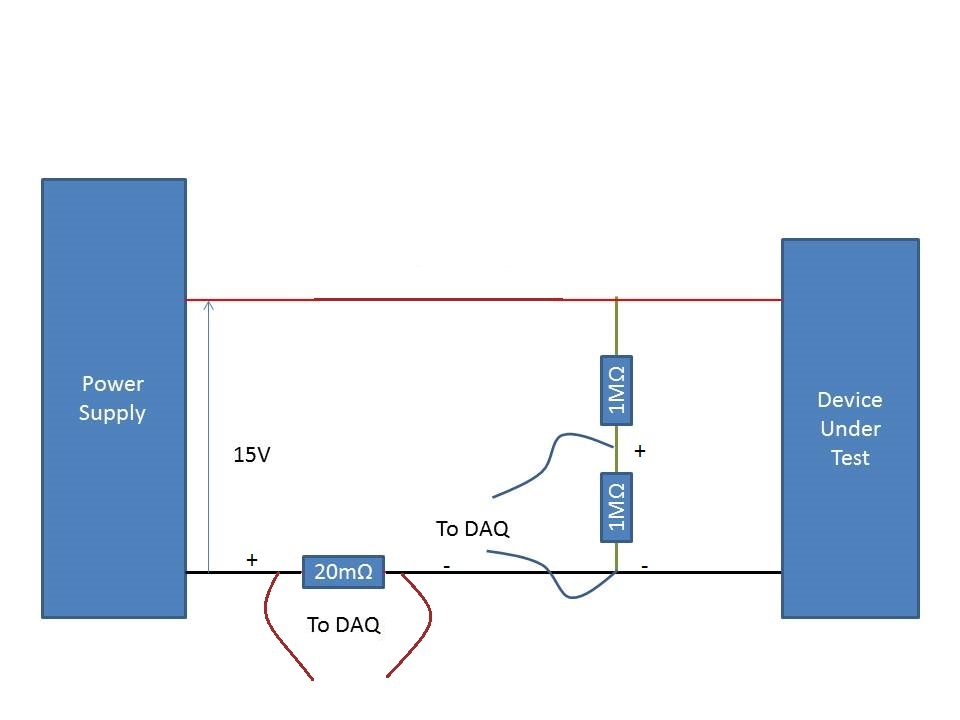

I am attemting to measure the current and voltage on a 15V power rail. (Here is a copy of my circuit attatched) I am using a USB-6225 DAQ and Lab View,

I have my device under test connected to a power supply. I have connected two differential channels to the DAQ, one for the current and one for the voltage.

I understand that the DAQ can not handle more than 10V so I use a voltage divider to half the voltage. When I run the measurements, the current reported is incorrect. It shows 10A when it should be about 500mA.

When I reduce the voltage on the power supply to 10V, it all works fine, so I am guessing its got something to do with the 10V limit.

Please can you advise how I can connect this up correctly?

Solved! Go to Solution.

03-20-2014 10:30 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Why are you posting a hardware issue to a software forum?

(Mid-Level minion.)

My support system ensures that I don't look totally incompetent.

Proud to say that I've progressed beyond knowing just enough to be dangerous. I now know enough to know that I have no clue about anything at all.

Humble author of the CLAD Nugget.

03-20-2014 10:37 AM - edited 03-20-2014 10:42 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

R(Sense) should be within 10 volts of the DAQ chassis. Thats all the common mode rejection you are likely to have on a DAQ device. (But check your device specification sheet ---- don't trust me RTFM!)

if you do not have a common "Ground" between the DAQ device and the supply you are monitoring you will need an opto-coupler (But any first year EE student could tell you that)

As an Asside.: Who the hell ever started the convention of stuffing R (sense) on the + side of a circuit anyhow? Use a regulated supply with "Remote sensing" if you really care about the DUT power consumption.

"Should be" isn't "Is" -Jay

03-20-2014 10:52 AM - edited 03-20-2014 10:55 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Do it this way.

=== Engineer Ambiguously ===

========================

03-20-2014 11:14 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Great, that worked!

Thank you very much for your constructive feedback and suggestion, much apprecited!

03-20-2014 02:10 PM - edited 03-20-2014 02:27 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

High side current sensing does prevent ground disturbances for sensitive or high speed PWM/Inverter circuits.

I think it can be used for additional diagnostic info that low side can't provide, can't recall.

EDIT: Forgot- with high side you can use multiple sensors to monitor current of multiple loads on a common ground buss.

Never had a need to use it though.

-AK2DM

"It’s the questions that drive us.”

~~~~~~~~~~~~~~~~~~~~~~~~~~