- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

How to convert digital signal to analog

02-05-2015

09:44 PM

- last edited on

10-14-2025

01:29 PM

by

![]() Content Cleaner

Content Cleaner

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi..

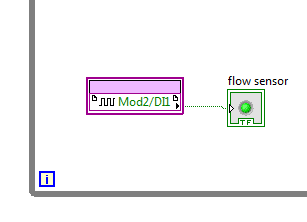

I am using NI 9375 (DIO module) to read the output from flow sensor.

The output of the flow sensor is in the digital signal.(Boolean=True/False).

How can I convert the digital signal to the analog to get the reading of the flow sensor?

I had tried before to convert the digital signal to the frequency so that I can make the conversion from frequency to the flowsensor reading,

but it doesn't work.( I am referring to https://www.ni.com/en/shop/compactrio/do-more-with-labview-fpga---c-series-digital-modules-using-com... ).

02-05-2015 09:54 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Mike...

Certified Professional Instructor

Certified LabVIEW Architect

LabVIEW Champion

"... after all, He's not a tame lion..."

For help with grief and grieving.

02-05-2015

10:03 PM

- last edited on

10-14-2025

01:33 PM

by

![]() Content Cleaner

Content Cleaner

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@nhan91213 wrote:

Hi..

I am using NI 9375 (DIO module) to read the output from flow sensor.

The output of the flow sensor is in the digital signal.(Boolean=True/False).

How can I convert the digital signal to the analog to get the reading of the flow sensor?

I had tried before to convert the digital signal to the frequency so that I can make the conversion from frequency to the flowsensor reading,

but it doesn't work.( I am referring to https://www.ni.com/en/shop/compactrio/do-more-with-labview-fpga---c-series-digital-modules-using-com... ).

FYI - If your flowmeter pulsing frequency is higher than 500Hz then you won't get reliable reading using your algorithm, and it will be very unreliable above 1kHz because fastest that loop runs is 1mS (1kHz). In that case you could tie the timed loop to a higher rate (hardware) clock source to go faster than 1mSec loop time. If no hardware then I think you can use high resolution timer (in LV2014, not sure if it was also available in previous version) and a regular while loop with algorithm modification for a faster timing.

02-06-2015 01:58 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@mikeporter wrote:

What do you mean by "it doesn't work"? How fast is the pulsing? Are you sure you are getting a nice clean signal? What is the output level from the sensor?

Mike...

Mike,

when I run the vi and the flow sensor is on, the indicator for counter and period didn't give any value.

The frequency range for output signal is 0.3Hz - 200Hz.

02-06-2015

02:02 AM

- last edited on

10-14-2025

01:33 PM

by

![]() Content Cleaner

Content Cleaner

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@BTC_Admin wrote:

@nhan91213 wrote:

Hi..

I am using NI 9375 (DIO module) to read the output from flow sensor.

The output of the flow sensor is in the digital signal.(Boolean=True/False).

How can I convert the digital signal to the analog to get the reading of the flow sensor?

I had tried before to convert the digital signal to the frequency so that I can make the conversion from frequency to the flowsensor reading,

but it doesn't work.( I am referring to https://www.ni.com/en/shop/compactrio/do-more-with-labview-fpga---c-series-digital-modules-using-com... ).

FYI - If your flowmeter pulsing frequency is higher than 500Hz then you won't get reliable reading using your algorithm, and it will be very unreliable above 1kHz because fastest that loop runs is 1mS (1kHz). In that case you could tie the timed loop to a higher rate (hardware) clock source to go faster than 1mSec loop time. If no hardware then I think you can use high resolution timer (in LV2014, not sure if it was also available in previous version) and a regular while loop with algorithm modification for a faster timing.

The output signal are:

Frequency range : 0.3 Hz - 200 Hz

Output Pulse : 5 msec +/- 25%

02-06-2015 02:39 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

02-06-2015 07:34 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

GerdW wrote:

Btw. I would do the counting in the FPGA. No need to have the RT part loaded with such a simple task…

I usuallly use the FPGA to get the time between pulses and pass that value up to the RT. The RT can then perform the math to get your flow rate. The FPGA is a lot more accurate for counting the time than the RT since it is actual hardware timed instead of software timed.

There are only two ways to tell somebody thanks: Kudos and Marked Solutions

Unofficial Forum Rules and Guidelines

"Not that we are sufficient in ourselves to claim anything as coming from us, but our sufficiency is from God" - 2 Corinthians 3:5

02-06-2015 12:27 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@crossrulz wrote:

I usuallly use the FPGA to get the time between pulses and pass that value up to the RT. The RT can then perform the math to get your flow rate. The FPGA is a lot more accurate for counting the time than the RT since it is actual hardware timed instead of software timed.

I too recommend this method. I do the same but with PWM measurement or PWM generation. Have the RT calculate the frequency and duty cycle based on the value of the pulses from the FPGA. RT can handle the floating point math much better.

Unofficial Forum Rules and Guidelines

Get going with G! - LabVIEW Wiki.

17 Part Blog on Automotive CAN bus. - Hooovahh - LabVIEW Overlord

02-08-2015 07:57 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@GerdW wrote:

Hi nhan,

you count the pulse. Just get the difference of the pulse count each second to get your frequency…

Btw. I would do the counting in the FPGA. No need to have the RT part loaded with such a simple task…

Hi GerdW,

tq for the reply.

I am new to labview,I have no idea on how to count the pulse. The ouput signal for the sensor is true/false.

If you don't mind, can you show me the example on how to count the pulse.

02-08-2015 08:06 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@Hooovahh wrote:

@crossrulz wrote:I usuallly use the FPGA to get the time between pulses and pass that value up to the RT. The RT can then perform the math to get your flow rate. The FPGA is a lot more accurate for counting the time than the RT since it is actual hardware timed instead of software timed.

I too recommend this method. I do the same but with PWM measurement or PWM generation. Have the RT calculate the frequency and duty cycle based on the value of the pulses from the FPGA. RT can handle the floating point math much better.

Hi Hoovahh and crossrulz,

tq for the respons.

I appreciate if you can show me the examples on how to get the time between pulses or with PWM..

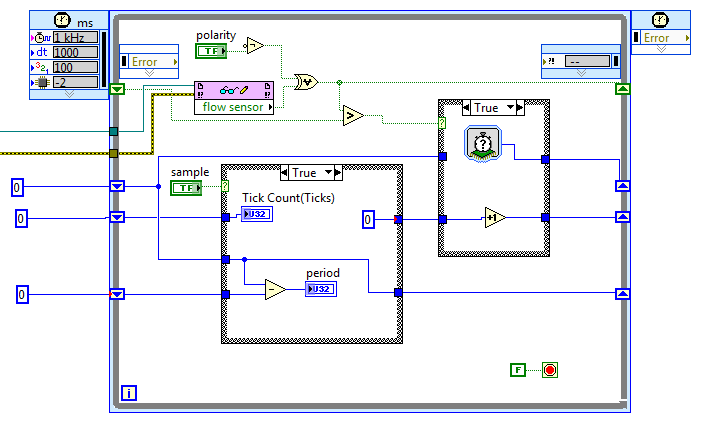

Below is what i've done but the count or period doesn't give any value.