- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Hello, i am a new user of labview and i have trouble finding a way to calculate air presure in the tank

01-06-2023 05:35 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

I need to calculate air presure in the tank and i know tank's volume, input presure [pin] and output valve opening percentage [n]. I have to make a LabView aplication which i can introduce [pin] and n and my aplication should be able to calculate presure in the tank.

01-06-2023 07:53 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Do you have a formula to calculate this?

If you do it should be easy enough to build in LabVIEW

01-06-2023 12:21 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@Nick21C wrote:

I have to make a LabView aplication which i can introduce [pin] and n and my aplication should be able to calculate presure in the tank.

Then you should do that.

If you are stuck then you should provide some details of what you have tried and how you are stuck. You have not asked any questions, so you should not expect many answers.

01-07-2023 08:58 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Attach your efforts (be sure to attach the .vi files you create so that we can test your code). Pictures of code can also be helpful for those that might not have the latest version of LabVIEW installed. But please don't ask us to do your homework for you ... there is plenty of tutorial material available, both on the first page of this Forum and on the Web.

Bob Schor

01-08-2023 10:21 AM - edited 01-08-2023 10:29 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@Nick21C wrote:

I need to calculate air presure in the tank and i know tank's volume, input presure [pin] and output valve opening percentage [n]. I have to make a LabView aplication which i can introduce [pin] and n and my aplication should be able to calculate presure in the tank.

Is this a (1) simulation where [pin] and [n] are controls on the front panel or (2) a hardware application where these measurements obtained from external hardware?

LabVIEW does not really care where the inputs come from, so start with a simulation. You can implement the hardware connections later with a few trivial changes:

- Place two controls on the front panel, one labeled "pin" and one labeled "n", unless you can come up with more descriptive terms. Decide on a useful datatype and control style (e.g. sliders)

- I assume the "volume" is constant, so that can be a diagram constant for now.

- Place a numeric indicator on the front panel and label it "pressure". decide on a useful style (e.g. gauge).

- No you have three terminal on the diagram, two data sources and one data sink.

- If you interactively want to use it and see the results as the inputs change, surround the terminals with a while loop.

- Decide how fast the loop should spin and place an appropriate wait (e.g. 100ms is sufficient).

- Now implement the math to calculate the output from the two control inputs and volume using the plain tools in the numeric palette and wire things up. What are the formulas? Is the math simple or do you need to tap into calibration curves? Is this an ideal gas? Is the input pressure constant or well regulated? How big is the valve compare to the volume?

- Run the VI, change the controls and watch the result. Make sure the result is correct.

- Easy! Right?

01-08-2023 10:24 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Thank You for indications, I will try.

01-12-2023 11:47 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

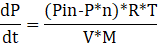

hello, my formula is :

where: pin=1atm

n=100%(full oppened), R=8.314,T=25C,V=2,M=29

01-12-2023 02:15 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

So were you able to complete the assignment?

If you give a formula, you should give units for all parameters (e.g. P, F, M, t). Well, we can guess, of course.... 😉

So you have a differential equation. Did you solve it? What is the starting pressure of P? Is Pin the outside pressure? I guess after an infinite time, P=Pin. Are you sure n is percent (0..100%) and not fraction (0..1)?

Do you have a link where you got that formula?