- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Monitoring a Watlow F4 Controller

Solved!08-28-2013 01:23 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hello,

I have the similar problem as yours. I know the post has been here for 2 years, I still hope that I can get some tips from you.

I amusing the the Espec chamber with watlow f4 controller and it faill on the MAX read.

Can you specifiy your setting on the MAX.

The Baud rate is 9600. What is your flow control.

Thanks!

09-10-2013 01:38 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

boy did they hide that in the manual!!!!!!!!!! I'm working on integrating a group of temperature chambers so we can run them from a common frame. At first I implemented a bunch of basic functions, but when it comes to doing a ramping profile the Watlow controller (connected to a Thermotron chamber) didn't work well by sliding the set point. So I had to take the time to figure out how to program ramping profiles. The other 2 chambers were okay, but the Watlow was a pain. I was looking for a way to terminate a profile for when the user wants to abort the program, and I actually called Watlow (still waiting for a call back). That's a big help.

While I'm at it, is there a way to find out if a profile is active? I would like that for when I query the set point. If it's in static mode it's in one location, and if a profile is running its in another location. This would prevent me from having to store the profile status inside the class structure.

Thanks,

Mike

09-11-2013 12:41 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

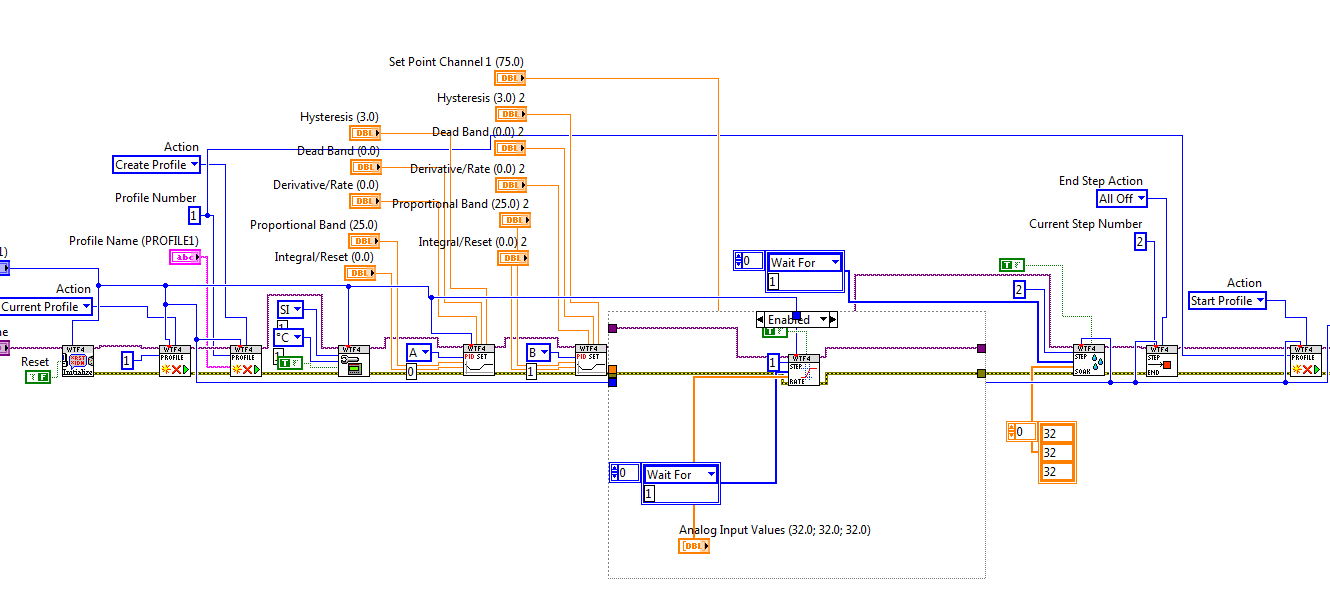

Took awhile but I was able to find it. Check out the snippet below. You use the Monitor Current Step.vi and select the Current Profile File Number. Have a great day.

The snippet is for 2013 but you should be able to find the VI in the Instrument Drivers. Also in the future if a post is inactive for awhile it is usually better to post in a new forum and reference the older one.

Systems Engineer

Academic Research

National Instruments

09-24-2013 01:27 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Okay, next item. I was able to program a ramping profile. I normally use the controller in static mode, and then switch to profile mode when I want to do the ramp. The bug that is sneaking in is that when I go to start the profile the chamber shuts off, and then I have to manually start it programmatically. The issue with that is that if the chamber is at a cold temperature the temperature imbalance can damage the chamber. Not Good. Soooo, I took a few steps back, and when I stopped running into stuff (snicker, snicker), I noticed a few things.

1) We also have the Watlow program that works very well. I noticed that for each of the steps the digital outputs (which are configured as event outputs) can be turned off or on during the profile. So I found the section in the manual that deals with ramping, and item 2 specifies event outputs to turn on or off (if digitial outputs are set up as events).

2) I looked at the examples and the VI's and they don't show (or I can't see it) where I can program the event for the profile steps.

I already found one bug in the examples. Think I'm going to find 2?

Any suggestions? Guess it's back to burying my head in the manual.

Mike

09-24-2013 01:47 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

I found it!!!!!!!!!!!

In the example they had they were using the VI Insert Ramp Time Step Event, and one of the controls they didn't wire anything to was Event Outputs. will try it and let you know if that works.

Mike

11-15-2013 08:24 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hello,

I am in a similar situation. I have a chiller machine connected to a Watlow F4 controller. I want to set the temperature setpoint so that the chiller responds and moves towards the setpoint. For example, if the current temp is 40C and the setpoint it 20C the program will tell the chiller to cool the temp until it reaches that and vice versa when the setpoint is higher than the current temp it will heat the water. I attached my current code which is based off the watlow F4 driver library. So far I've only been able to turn on the chiller by setting digital output 1 high and turning on the compressor to cool the water by setting digital output 8 high. If someone could provide some help it will be greatly appreciated. Thanks!

Eric

01-21-2014 03:01 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

I have the watlow f4d controller and I am trying to set the specific ramp rate for my profile. I was able to communicate well, set the temperatures, setting profiles and all. But there are oscillations in the temperature and it is taking too much time to reach the set point.

Two issues,

1. Too much time taking to reach the set point temperature

2. In the below code, when guarenteed soak was set, the soak is happening forever and the soak time in controller is not reducing at all.

PLease suggest if any one has a possible solution.

01-22-2014 06:09 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi suryajjj,

Are you able to confirm that you can communicate with the instrument and create the profile properly?

Also, do you get an error message at all?

Applications Engineer, National Instruments

CLD, CTD

06-10-2014 04:53 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hello labviewleroy,

From your post ...09-20-2011 04:11 PM.....

I would like to try your sample code on LabView 2013. Can you please send me an updated code?

Also, just for your info, here's my setup:

Chamber: ESPEC BTL-433

Controller: F4D Watlow

COM Port 4 : 19200 Baud

Via Laptop Windows 7 through NI USB -232 adapter.

Do you think, my setup will be compatible?

Many Thanks

06-10-2014 05:53 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

sure buddy. Just so happens I happe to have the code easily accessible.