- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

Robot Control by imitating human motion

by

Mohamed Flifl1 and Ayman A.El-Badawy2

1: Mechatronics Department undergraduate student

2: Associate Professor of Mechatronics Engineering

German University in Cairo

Egypt

Products Used:

National Instruments LabVIEW™, Vision™

Version 9.0

The Challenge:

Developing a real time trajectory from the motion of a human’s hands. This trajectory is to be used

later to make the robot’s end effector imitates the operator’s hands motion in 3-dimensional space.

The Solution:

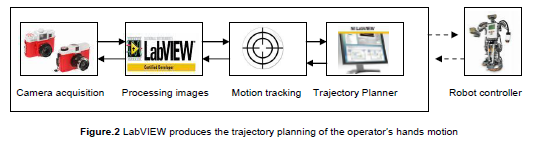

By implementing several computer vision and image processing techniques, the position, velocity and

acceleration of the operator’s hands are calculated as a function of time and then used as the realtime

trajectory plan for the robot’s end-effector. Here the output signals are monitored in LabVIEW

front panel with graph indicators in real time.

Abstract

Robots can do most of human’s jobs faster, easier and more accurate, but how to control robots and

what is the most efficient way to control a robot? This project looks at facilitating the control of robots

by means of webcams. The webcams are the only input devices where the operator’s hands trajectory

would be detected and at the same time the robot would mimic this trajectory using an appropriate

model. The hypothesis is that if the robots are controlled by imitating an operator’s motion, it would be

easier and better, as the robot motion would be without any tremble that could happen because of

human’s movement, so it would be more efficient. This project can be used in many applications, for

example, gaming purposes, or to imitate the surgeon motion to operate on a patient over long

distances and in a safer manner. The experimental results supported the hypothesis by showing the

real time values, and thus the project met the design criteria.

Figure.1 Robot imitates human motion

Introduction

The Vision-Based Robot Control technique, which is also known as “Visual Servoing”, is implemented

using binocular vision (two cameras) in a stand–alone configuration. The tracking system consists of

two cameras fixed together by a well known distance and connected to a PC via USB port. These

cameras would be in a stereo arrangement to provide complete 3D information about the scene.

Consequently, the depth estimation would be accurate The cameras are able to capture an image or

video at a frame rate of 30fps. LabVIEW 2009 is used to develop the path plan (position, velocity and

acceleration of the end-effector), where the acquisition of images is done by using the IMAQdx driver.

Further processing and analysis were implemented using NI IMAQ Vision. The cameras are

employed as a global sensor, and the robot would be separated from the framework, as it would be

controlled according to the operator’s movements in 3-dimensional space.

Trajectory Planning Algorithm

The difficulty of the Tracking algorithm is to implement a smooth tracker for the operator’s hands

motion, which has unpredicted motion and irregular shape that cannot be detected by pattern

matching or blob detection. Thus, an image subtraction algorithm is used in this project to recognize a

moving object according to its motion. The major reason for using this algorithm is that it is simple and

can be implemented with limited real-time processing capabilities for each camera, and then the

processing time for both cameras would be minimized. And it turned out to work acceptably well.

Camera acquisition Processing images Motion tracking Trajectory Planner Robot controller

The algorithm starts by choosing two regions of interest (ROI) which will be the tracking boundaries

for each hand. There was no need to use color formats (i.e. RGB) which may increase the processing

time unnecessarily, thus all processed images were converted to grayscale type. The cameras should

acquire at the beginning a background image, then it will be subtracted from each processed frame to

give a clear image of the moving object. After that, simply the previous frame image will be subtracted

from the current one. The result of the two successive subtraction operations will only show the

moving object on the framework of the image.

The mean value of the resulting image is determined and then multiplied by a pixel gain that is then

compared with a threshold value. This threshold value determines the beginning of the operation of

the tracking algorithm. In other words, the tracking algorithm will work if the mean value exceeds the

threshold value. After that, there would be four real time processing stages: 1. Segmenting the image

such that the object only appears as a set of white pixels, 2. Implementing a morphological filter to

remove any noise in the image utilizing erosion technique, 3. Calibrating the image in order to

transform its coordinates to the real world coordinates including the scaling factor, 4. Determining the

position of the object by calculating the centre of energy of the filtered image for each region of

interest. This position is then converted to the real world coordinates according to the applied

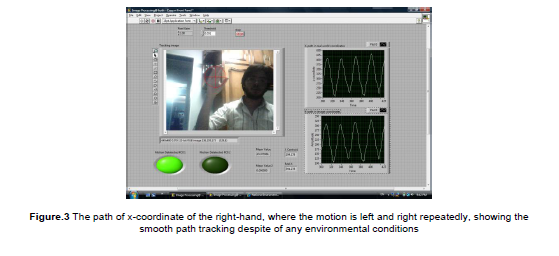

calibration rule. Finally, the determined X and Y coordinates can be indicated by overlaying a circle on

it with a noticed color.

Using numerical techniques, the coordinates’ values are differentiated once in order to get velocity,

and twice for acceleration. These outputs can then be used in an inverse kinematics algorithm to

control the motion of the robot joints.

Stereovision technique

Each camera is connected to a separate frame grabber where neither the cameras nor the frame

grabbers are synchronized. The IMAQ Start VI is called almost simultaneously for both acquisitions,

meaning that the next available frames from both cameras will be displayed. This mode acquires

images at a rate of 30 fps per interface since the cameras are connected to separate frame grabbers.

This mode can be enhanced by using another type of cameras (more expensive) to be 15 fps per

camera, but the results were acceptable compared to this approach.

It is relatively simple to implement a depth perception using any custom algorithm to get the best

results for the application. With the two cameras, each will follow the tracking algorithm in order to

detect the object, and then the pixel coordinates from both images will be compared, and finally a

stereovision triangulation algorithm would be applied translating the pixel position discrepancies into

distance and size. Consequently, the depth coordinate (z-axis) would be monitored using a graph

indicator referenced from a pre-initialized value, which refers to the real world coordinates.

LabVIEW was the best software for implementing an image processing, computer vision, and

visual servoing applications in real time

Most of image processing and computer vision applications implemented using C programming, but

stereovision applications would be very complex in its implementation and troubleshooting. So, IMAQ

Vision and LabVIEW were used for initial design and testing. Advanced signal processing features of

LabVIEW, such as filtering, significantly facilitate the program implementation. Moreover, the FPGA,

Real-time, and motion modules will conclude in a very efficient visual sevoing system working in real

time. Consequently, LabVIEW and National Instruments products are the first choice for all visual

applications.