- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

NovaBike08 Data Acquisition: myRIO as mainframe for collecting data of an electric racing motorcycle

UPDATE: MotoE 2017 Champion

The final race weekend of the MotoE competition took place on the 7th and 8th of October 2017, at the beautiful racing track of Donnington Park, UK. During the final, deciding race for the competition, there were two teams were still in the running for the MotoE 2017 championship; Nova Electric Racing and Bath Zero.

As with every race, it was an amazing spectacle to see the power of the NovaBike08 being used to leave both petrol bikes and Bath Zero's bike behind us, and win the race! This important victory sealed the championship and Nova Electric Racing is now the proud title-holder of MotoE champion!

The season-concluding article published by the MotoE: http://motoeracing.com/2017/10/10/congratulations-nova-electric-racing/

NovaBike08 Championship Video

Contact Information

Country: The Netherlands

Year Submitted: 2017

University: Delft University of Technology

Author: Arjen Kremers

Email Address: arjen.kremers@novaracing.nl

Project Information

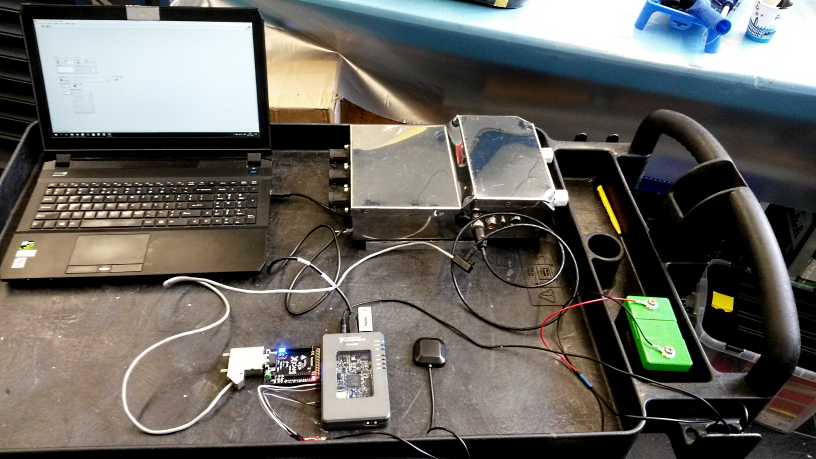

Title: Data Acquisition for the Nova Electric Racing motorcycle using the NI myRIO

Description: To gain insight in the performance of the NovaBike08 electric racing motorcycle, a data acquisition system was developed to have a centralized way of storing the measurements of all powertrain systems and introducing new measurements including GPS and accelerometer.

Products: myRIO-1900, Stratom X-CAN

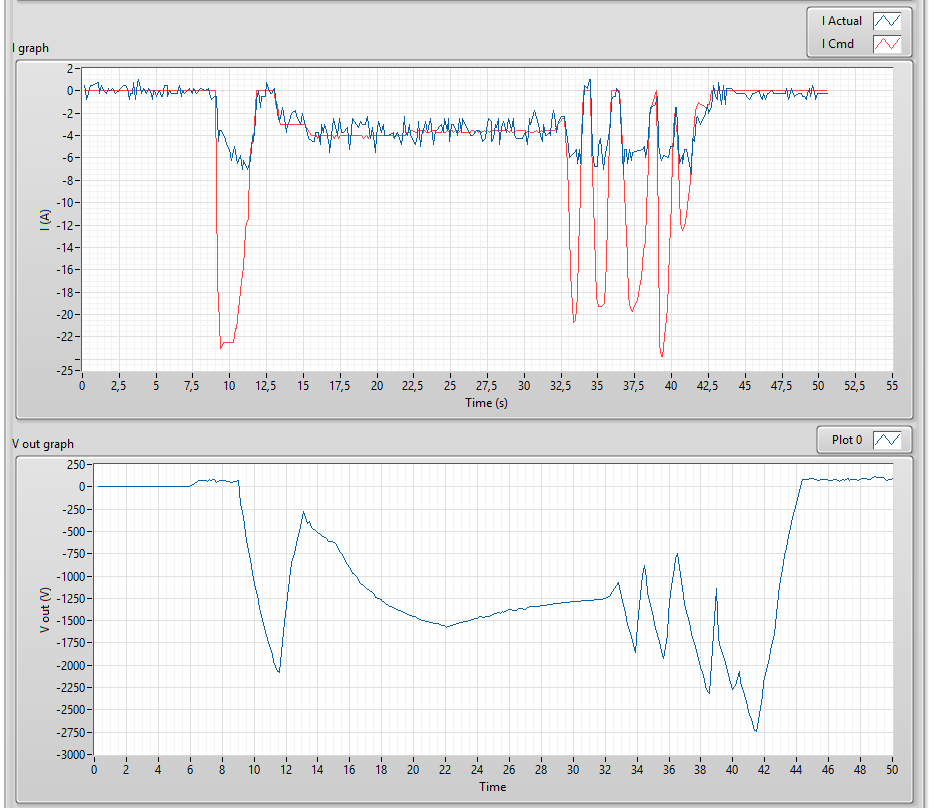

The Challenge: Motorcycle racing is a very fast and agile sport, where timing is extremely important. The data acquisition has to be able to communicate fast enough during the race and store data efficiently in order to maximize sample rates of all the different measurements that should be performed. For example, it must be possible to show the performance difference between applying the regenerative braking smoothly and doing so 200 ms later but more abruptly.

The Solution:

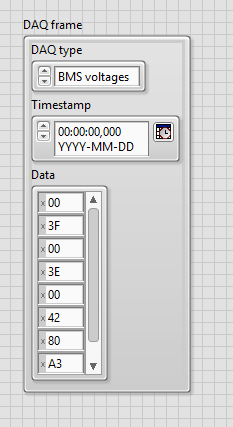

DAQ File Format

The slowest operation of a computer is usually file I/O, so the first system to be developed was the file format in which the acquired data would be stored.

This binary file format consists of any amount of frames, where each frame contains an enum indicating the type of data, the timestamp of the millisecond the data was collected and the actual data bytes of the measurement. This allows for reducing the amount of bytes written as much as possible, also due to the fact that CAN messages contain up to 8 bytes, forcing systems to pack their message data efficiently.

File I/O is usually slow because the processor needs to wait for the operation to finish before continuing, and therefore blocks the execution of measurements. This has been solved by implementing a queue of frames that can be accessed by measurement VI's to store their data in. This queue is polled constantly by the file writing VI, but in a different thread, allowing the measurements to continue while the files are written to a removable storage device. In this project the USB port of the myRIO is used together with a USB storage device to store the DAQ files.

CAN-bus

The BAMOCAR D3 motor controller of the motorcycle and also the Emus BMS (battery management system) both support and use CAN-bus communication to request data or configure the device. With the Stratom X-CAN module plugged into this CAN-bus as well, all messages placed on the bus can be read, and requests for specific messages can be written to the bus conveniently.

Both the CAN protocol of the motor controller and BMS have been implemented on the myRIO. Each incoming CAN message is filtered on its identifier to know what type of measurement it is, and converted to the right DAQ type accordingly.

GPS

The racing tracks the NovaBike 08 will race on are not straight roads, but have many different corners that all have their own optimal approach speed and drive line. It is therefore useful to be able to link each measurement (or its timestamp) with a location on the track. This has been realized using the SparkFun GPS module. It can be communicated with over UART which has a very easy-to-use LabVIEW interface. The NMEA messages coming from the module are used both to log the latitude-longitude data and to synchronize the date and time settings of the myRIO with GPS when starting the system, due to the absence of an on-board Real Time Clock.

Analog Measurements

Other measurements will be performed by the myRIO itself or by connecting sensors to the myRIO directly. Acceleration, for example, is measured using the built-in accelerometer of the myRIO and is also logged to the USB drive periodically.

Other useful measurements that are yet to be implemented are the wheel speed sensors, brake pressure sensors and a simple voltage divider to monitor the voltage of the auxiliary voltage system of the bike.

Conclusion

The first tests with the Data Acquisition system connected to the most essential powertrain components of the motorcycle, the motor controller and battery management system, appear useful. For the first dynamometer test of the bike it is planned to get an indication of the internal resistance of the battery pack and the accompanying losses in heat. The interesting measurements for this test are the total battery pack voltage by adding up all individual cell voltages as measured by the BMS compared with the input DC voltage at the motor controller. Then together with the current through the battery pack, measured by the BMS, the losses of the battery pack can be estimated. The choice of the NI myRIO as main control unit and its platform to extend on already provided the system with many functionalities and requirements, like the accelerometer and fitting in the dimensional restrictions.

The Nova Electric Racing Team with the NovaBike07

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

An incredible bike from an incredible team! A million congratulations to Nova Electric Racing and TU Delft for the MotoE victory!

Senior Marketing Engineer, National Instruments

Connect on LinkedIn: https://www.linkedin.com/in/richard-roberts-4176a27b/