From Friday, April 19th (11:00 PM CDT) through Saturday, April 20th (2:00 PM CDT), 2024, ni.com will undergo system upgrades that may result in temporary service interruption.

We appreciate your patience as we improve our online experience.

From Friday, April 19th (11:00 PM CDT) through Saturday, April 20th (2:00 PM CDT), 2024, ni.com will undergo system upgrades that may result in temporary service interruption.

We appreciate your patience as we improve our online experience.

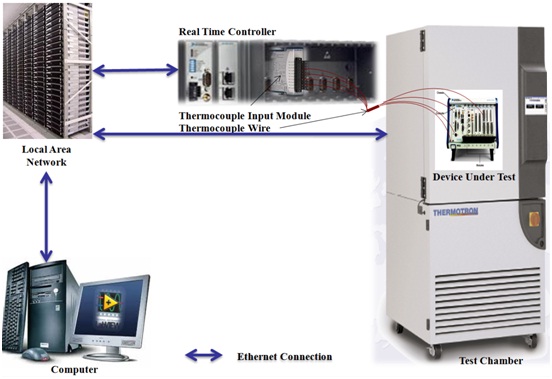

This project consists of an automated real time system that provides temperature monitoring and logging, and a standalone software for remote test chamber control. The system user interface can be accessed remotely with a computer connected within the local area network.

NI cRIO-9074

NI 9211

NI 9213

NI LabVIEW 2010

NI LabVIEW Real Time

A target Device Under Test (DUT), an embedded controller is needed to undergo the Verification and Validation (V&V) testing. The test involves temperature test, Highly Accelerated Life Test (HALT), power dissipation test and storage test. All the mentioned tests require input data of temperature measurements from the DUT for further analysis. The measurements are taken from different parts of the DUT, for instance the memory, processor, power supply and others. In collecting temperature data, a test chamber is used to apply various test temperatures on the target DUT at each time instance depending on the test method used. The existing system currently used to collect the temperature data is an automated real time Thermal Logger. It uses a real time controller which has connected thermocouple input modules that measure temperature using thermocouple wire. The software and user interface is programmed using LabVIEW. It features real time thermal monitoring and logging. R&D engineers had experienced several limitations and stability issues of the existing system. The system is fixed with 24 measurement channels, thus, measurement above 24 channels is not possible for future distributed measurement extension. A single strip chart for all 24 measurements resulted in a crowded waveform plots and caused difficulty in monitoring each measurement channel. The system is reported for occasional breakdown, where the user interface is non-responsive and the logging stopped unexpectedly. Hence, a new system that is robust and supports future extension is required to provide reliability and flexibility for future V&V test. In this project, a new system will be designed and developed to solve the limitations and issues of the existing system.

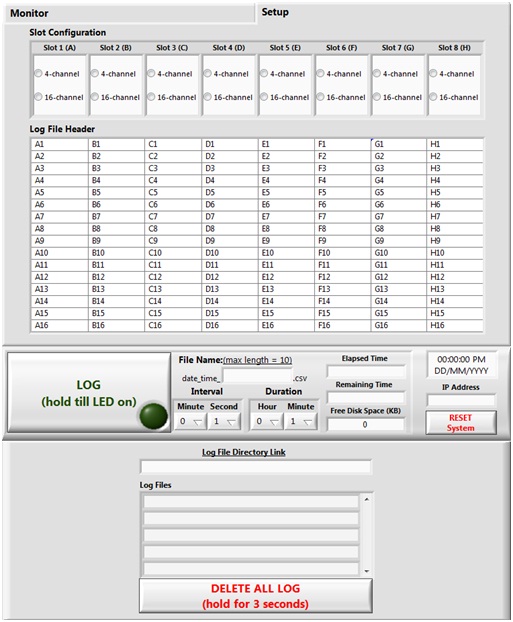

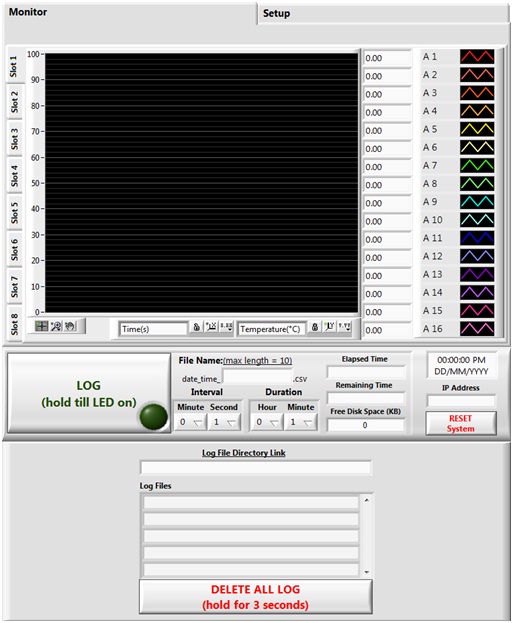

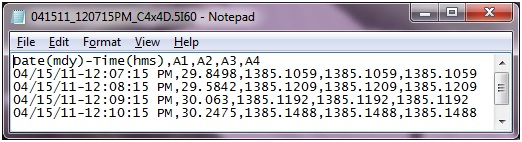

This project aims to develop a new system for the V&V test temperature data collection to enhance existing system used. In the new system, the temperature monitoring features multiple strip charts to solve the visibility problem of crowded waveforms. It also provides configurable measurement channels to provide support for future distributed measurement extension up to 128 channels. The temperature logging provides new customizable log file name and header to improve file management and data analysis. The system is improved to support logging up to 24 hours. The new system also provides new standalone software which allows remote test chamber control where user can access, monitor and control the test chamber remotely from a computer connected within the local area network. Several improvements and enhancements is implemented in the new system at each feature category to enhance the usability and reliability of the system. Above all, the temperature monitoring and logging system is automated and provides real time temperature logging with accurate measurement value, while the remote test chamber control software is capable of executing all the basic functions available in the test chamber remotely.

This project is fully programmed using LabVIEW. The thermal monitoring and logging system uses an additional LabVIEW Real Time module to utilize the real time programming tools. LabVIEW contains a large collection of libraries with drivers and various functions to interface with different types of hardware for creating simple to complex measurement, test and control system. LabVIEW VI has became the mainstream direction of current instrument development due to its high efficiency, good interactive interface, convenience of system reconstruction and self-defining functions. System build using LabVIEW allows user interface control with keyboard and mouse, hence, resulting in a simpler hardware design and lower production cost. LabVIEW has also provided a virtual panel of friendly interface for the system design. The LabVIEW Real Time module has demonstrated to be very useful and much more effective and accurate than other present technology. Remote system access and control is observed to use ready-made remote control, web browser user interface and RFID receiver in respective system design. A remote web browser user interface was created for the thermal monitoring and logging system. It is the most practical solution as LabVIEW provides a convenient web publishing tool to create remote front panel which can be accessed from a web browser. Hence, cost induced for purchasing additional remote device can be avoided. Transmission Control Protocol (TCP) is one of the major rule used in network or internet communication. In creating the remote test chamber control software, TCP protocol is used to secure communication between the test chamber and a computer within a Local Area Network. The TCP protocol communication VI library is available in LabVIEW which allows quick prototyping and development of the remote test chamber control software.

system hardware configuration illustration

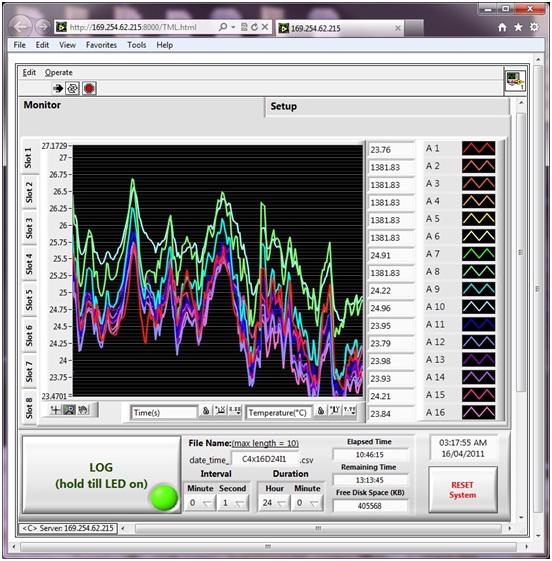

Remote Thermal Monitoring and Logging:

system setup page

system monitoring and logging control page

log file in notepad view

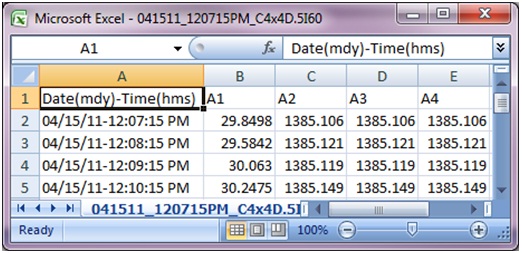

log file in spreadsheet view

remote system web browser user interface(front panel)

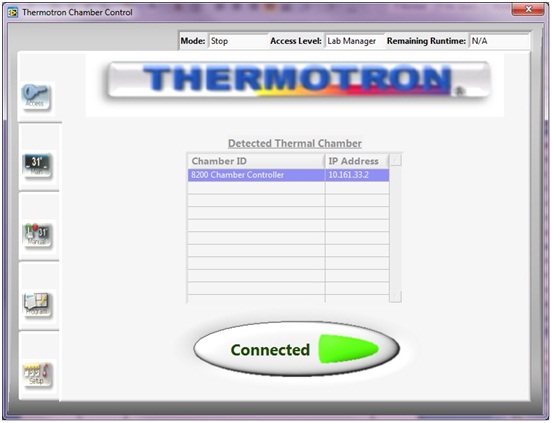

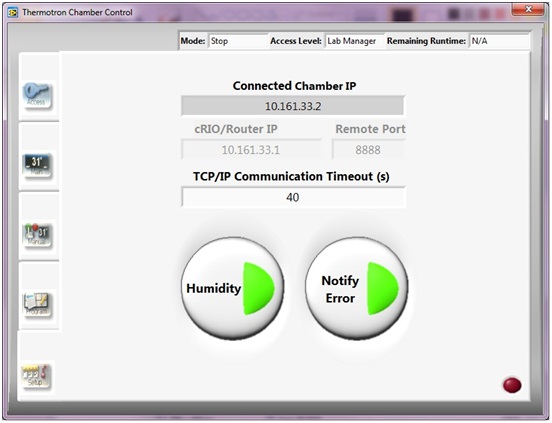

Remote Test Chamber Control:

chamber detection and connection page

setup page

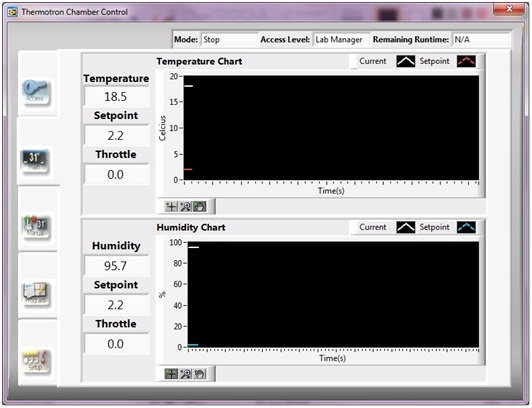

monitoring page

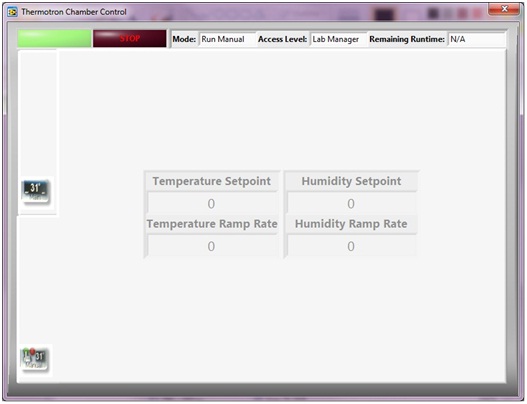

manual run mode page

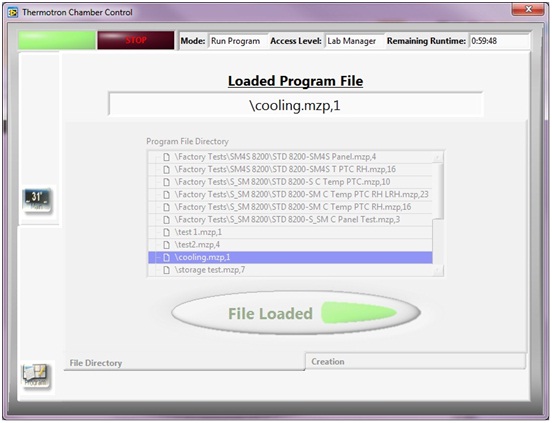

programmed run mode page

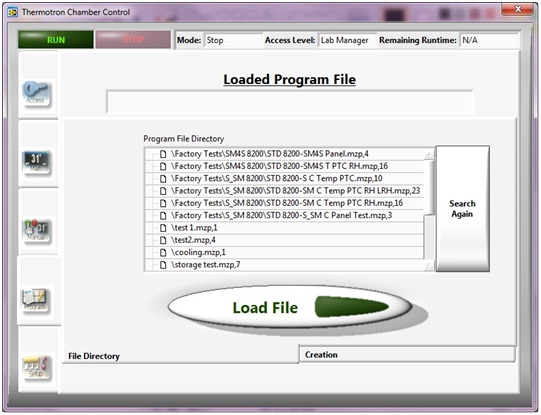

program profile detection and selection page

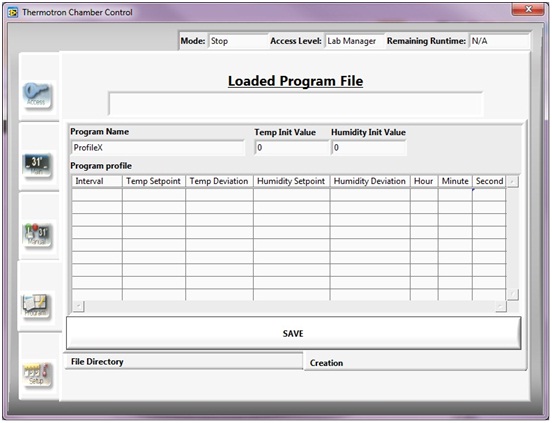

program profile creation page

This project is showcased on MMU Faculty of Engineering webpage: http://foe.mmu.edu.my/v2/main/undergrad/fyp_showcase/fyp_electronics.html

Example code from the Example Code Exchange in the NI Community is licensed with the MIT license.

Hey Kelvin,

Thank you so much for your project submission into the NI LabVIEW Student Design Competition. It looks great! Make sure you share your project URL (https://decibel.ni.com/content/docs/DOC-18615) with your peers and faculty so you can collect votes ("likes") for your project and win. If any of your friends have any questions about how to go about "voting" for your project, tell them to read this brief document (https://decibel.ni.com/content/docs/DOC-16409).

Good luck!

Jessica

I notice that if user were to click like and just close without logging out, the like is not saved.

Kelvin you are right, I pressed Like and once I go to other pages and get back to this page, my Like is gone. I got to logging out after I press Like. That's troublesom and hopes somebody fix it ASAP. ![]()

Thanks! Remember to click the "like" below the yellow arrow above to vote for me!