From Friday, April 19th (11:00 PM CDT) through Saturday, April 20th (2:00 PM CDT), 2024, ni.com will undergo system upgrades that may result in temporary service interruption.

We appreciate your patience as we improve our online experience.

From Friday, April 19th (11:00 PM CDT) through Saturday, April 20th (2:00 PM CDT), 2024, ni.com will undergo system upgrades that may result in temporary service interruption.

We appreciate your patience as we improve our online experience.

Contact Information

University: Liverpool John Moores University

Team Members (with year of graduation): Kieran Southward (2015)

Project Supervisor: Dr Christian Matthews

Email Address: k.southward@2011.ljmu.ac.uk

Project Information

Title: Development of a Four Cylinder IC Engine Control Unit for Formula Student

Description:

The aim of this project is to develop an engine control system with a high level of controllability and customisation, with the Intention of using it as the ECU for the LJMU Racing Team as the Formula Student competition.

Products:

Software:

hardware:

The Challenge:

The main aim of this project was to investigate the operation of spark ignition internal combustion engines, then designing and implementing an engine control system for a four cylinder engine. This was developed with the intention of being used on a CBR600RR engine for use by the university’s Formula Student team.

To be suitable for use by the LJMU Racing Team the ECU needed to have a high level of customisation and control over the operational parameters of the engine to allow the most out of the engine. Along with this base control of the engine, operation of the electronic throttle was also investigated as this is now allowed in the competition and provided a number of advantages to the team.

The Solution:

One of the main considerations when beginning the project was determine the necessary I/O in order to be able to control an engine and any additional I/O that would be required for desirable extra features. The NI powertrain control modules (DRIVVEN modules) were a clearly ideal solution to this, given they contained all the needed I/O and provided the majority of the interfacing circuitry needed to read the engines sensors and drive the actuators. The only additional circuitry needed is to use TTL signals to drive the coils. As well as this they also provide a number of sub vi’s that reduced the development time.

The main sensor inputs used are the engines can and crank sensors, these inputs are used in the FPGA to calculate the engine position in crank angle degrees. This information is then passed on to a vi on the real-time controller, as well as being used in the FPGA to calculate the correct timing to fire the injectors and trigger a spark for each of the cylinders. From the engine position the engine speed is also calculated to be used by other parts of the system. An engines cam and crank signals can also be simulated using the EPT sub vi provided, this has allowed for bench top simulation work to be done, allowing the rest of the system to be tested before the need for on engine testing. The mapping is currently set up with two maps using 2D look up tables with the throttle position and engine speed as the control variables. These maps provide the advance and fuel injection timing. This was set up as a desktop test bench, this can be seen in the figure 1 below. This has allowed the injector operation to be tested, the signals for the spark and allow for work to be done on an electronic throttle.

Fig 1 - ECU desktop test bench

Fig 1 - ECU desktop test bench

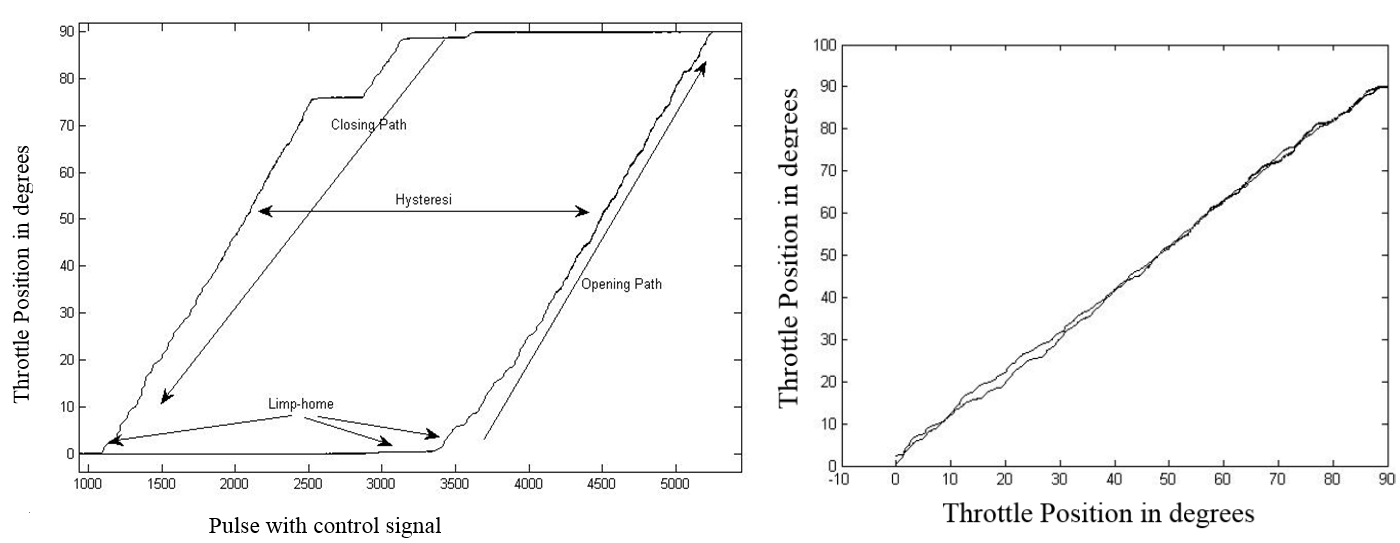

Electronic throttle control is also being investigated as part of this project, a version using provided sub vi’s is included as part of the main vi. The main development on the electronic throttle control is in a separate vi within the project. Here the control of the electronic throttle has been developed from the ground up. The main task in this was to remove as much nonlinearity and hysteresis of the throttle system as possible to allow it to be controlled by a PID controller. This was done by using static compensators, one for throttle opening, one for throttle closing. These were tuned by using a slow ramp of the throttle plate to give a baseline of the throttles behaviour. The results of the linearization can be seen below in figure 2.

Fig 2 - Original hysteresis on the left compensated result on right

Fig 2 - Original hysteresis on the left compensated result on right

Current level of project

The ECU is still within the testing stages of the development with the key parts of the system working. The ECU has successfully reached engine synchronization when the crank and cam signals where used from a CBR600RR. The effect of the timing options and the maps have been tested along with the TTL signals for the coils and the injectors have been driven. A video showing the injectors in operation can be seen below, with a potentiometer being used at simulate throttle position and engine speed. The next stage is to implement circuitry to interface allow the coils to be driven from the TTL signals. Once this is done the system will be ready for engine testing. The electronic throttle requires the tuning of the PID controller. This can then be integrated into the main vi.

Level of completion

As stated above the ECU still has some development work to be carried out, at the current stage I would class the project as being in alpha.

Time to build

This project was started 2013-2014 as my dissertation and carried over to the following year, to develop the electronic throttle component. Work as still been carried out on the ECU side this year but separate to my studies.