- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Wrong offset specifications for the SCXI-1125 module

06-01-2018 08:28 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

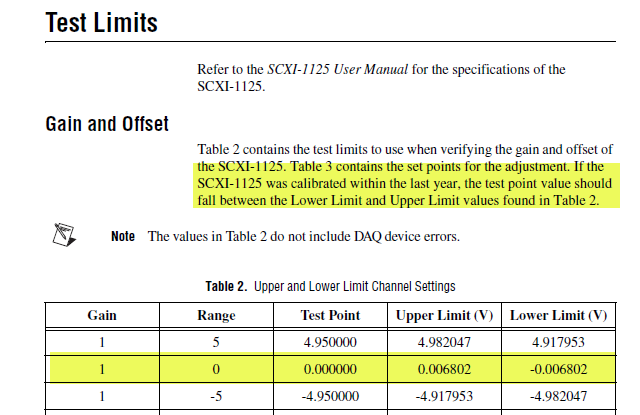

Could NI engineers please provide the correct offset specifications for the SCXI-1125 module? The last version of SCXI-1125 User Manual and Specifications (October 2009 - 372425c.pdf) has incorrect offset specifications which are also inconsistent with the last SCXI-1125 Calibration Procedure manual. Table 2 (Upper and Lower Limit Channel Settings) on page 13 shows the ±0.00680 mV error limit for 5 V range after one year, while the user manual specify the offset time drift of 3100 ppm of range/month. This is 0.0155 V/month and 0.0537 V/year. This is far too much. Something is wrong here. I need the correct values to calculate the measurement uncertainties for the whole system.

Thank you

06-01-2018 09:52 AM - edited 06-01-2018 10:13 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Don't mix up calibration specs and user specs...

The unit has to meet the calibration specs to make shure that due to drift (etc) the user spec will be hold over one year.

A calibration is always a snapshot of the current situation. ... you only can make an educated guess for the future ...

With a (calibration) history of your device you can make a better guess ...

The value of a standard is not the price you pay to buy it, it's the sum of the calibration and validation work you have spend 🙂

Without additional data a conservative MUB would use the user spec with rectangular distribution.

If you have offset data (with uncertainty) for your device of the past, that shows that your drift is smaller... BINGO otherwise you have to life with the data NI provides or spend the time for validation.

Henrik

LV since v3.1

“ground” is a convenient fantasy

'˙˙˙˙uıɐƃɐ lɐıp puɐ °06 ǝuoɥd ɹnoʎ uɹnʇ ǝsɐǝld 'ʎɹɐuıƃɐɯı sı pǝlɐıp ǝʌɐɥ noʎ ɹǝqɯnu ǝɥʇ'

06-04-2018 03:40 AM - edited 06-04-2018 03:44 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

The calibration test limits are derived from specifications.

The calibration test limits for gain 1 and 0 V test point setting are ±6.80 mV (0.00680 V), but according to specification they should be ±57.7 mV. Comparing with the previous versions of calibration and specifications manuals, there is most probably the mistake in the last version of specifications.

SCXI-1125 offset specification history:

- July 1999: ±0.5 mV/gain typical, 30 days after calibration ±0.3 mV/gain, 90 days ±0.6 mV/gain, maximum ±3 mV

- April 2008: ±5 mV (for gain 1 and after 1 year)

- October 2009 (for gain 1):

- Residual Offset Error = 200 ppm of Range

- Offset Time Drift = 3100 ppm of Range/month

- Offset Tempco = 54 ppm of Range/°C

- Example for gain 1 at 25 °C and after one day: (200 + 3100/sqrt(30)) × 10-6 × 5 V = 3.83 mV

- after one month: (200 + 3100) × 10-6 × 5 V = 16.5 mV

- after one year: (200 + 3100×sqrt(12)) × 10-6 × 5 V = 57.7 mV (or 1.2 % of range)

06-04-2018 05:39 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

I would say that the specs where changed due to

- more calibration data available (Ni started too optimistic)

or had to change some parts (due to discontinued production)

or both ...

so if want to declaire your device with lower uncertainties, you have to prove it with a calibration history of your device. (I use standards with an order lower uncertainty than declaired by spec, but they have sometimes more than 20 years of cal history 😉 )

Henrik

LV since v3.1

“ground” is a convenient fantasy

'˙˙˙˙uıɐƃɐ lɐıp puɐ °06 ǝuoɥd ɹnoʎ uɹnʇ ǝsɐǝld 'ʎɹɐuıƃɐɯı sı pǝlɐıp ǝʌɐɥ noʎ ɹǝqɯnu ǝɥʇ'

06-04-2018 08:02 AM - edited 06-04-2018 08:02 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

... or someone at NI has made mistake when writing October 2009 - 372425c.pdf specifications, because the NI calibration procedure document is newer (October 2015) and contain more realistic data in Table 2 of Verification Procedure.

06-04-2018 09:37 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Again: Don't mix up operation and calibration specs...

Calibration is done in closer (temp/emc) lab conditions and doesn't cover the hole specified temperature range.

However for your MUB: If you have a valid calibration for your device (or as already stated a calibration history), and run your device in similar lab conditions, you can argue with these values, just keep in mind that metrology is the art of knowing your uncertainty.

Don't fool yourself.

Never underestinate temperature effects.

So what is the uncertainty of your last (traceable) calibration ?

Henrik

LV since v3.1

“ground” is a convenient fantasy

'˙˙˙˙uıɐƃɐ lɐıp puɐ °06 ǝuoɥd ɹnoʎ uɹnʇ ǝsɐǝld 'ʎɹɐuıƃɐɯı sı pǝlɐıp ǝʌɐɥ noʎ ɹǝqɯnu ǝɥʇ'

06-04-2018 10:26 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Some brief history... over the years there have been some subtle changes to the cal limits and specs of the SCXI-1125, and they fell out of alignment at some point. So, a few years ago NI R&D attempted to remedy this by updating the SCXI-1125 cal doc, and the Calibration Executive software to align the calibration test limits to the specifications. The specifications were reviewed at the time and did not appear to have any mistakes, so only the calibration limits were updated.

When reviewing the formula that you used, I think I found the incorrect assumptions in your calculation.

1)The time drift for the offset error is intended to be the amount of time since the last self calibration - although I am not sure if this was explicitly documented anywhere. For the purpose of calculating the limit, the cal doc assumed 1 day of drift from last self cal.

2) The temperature drift assumption from last adjust is 10 degC (based on the 23C +/-5C calibration condition).

3) Noise error should also be included in the calculation, which you can calculate assuming 1000 averaged samples. So, the new calculation is:

[(200ppm + 3100ppm * sqrt(1/30) + 54ppm*10degC) * 5V/1e6]+8.6mV/sqrt(1000)] = 6.8mV. This should match the cal doc. These same assumptions should apply to the rest of the test points.

Logan K

06-05-2018 05:47 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@Henrik_Volkers wrote:

Again: Don't mix up operation and calibration specs...

Calibration is done in closer (temp/emc) lab conditions and doesn't cover the hole specified temperature range.

However for your MUB: If you have a valid calibration for your device (or as already stated a calibration history), and run your device in similar lab conditions, you can argue with these values, just keep in mind that metrology is the art of knowing your uncertainty.

Don't fool yourself.

Never underestinate temperature effects.

So what is the uncertainty of your last (traceable) calibration ?

The modules are new and there are no calibration history for them yet, therefore I have to start with NI data.

The offset time history will be lost because of the regularly offset self-calibrations. Or maybe the offset time history can be obtained by reading and storing the scaling coefficients (AI.DevScalingCoeff) of the module before execution of the self-calibration. But I’m not sure if I can do this, because first I have to know how the internal and external offset calibration data of SCXI module are used by DAQmx driver.

06-15-2018 07:00 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Logan you are right. I didn’t assume one day offset time drift in my calculations because the recommended calibration interval is one year. Now I get the same numbers as are in the SCXI-1125 Calibration Procedure manual. Thank you.

But I still doubt in given offset time drift specification. If I correctly understand, this mean that because of components aging, we can expect 2.8 mV output offset after one day, 15.5 mV after one month and 49 mV after one year. It seems unusually large to me. The value 3100 ppm of Range/year instead of Range/month would be more realistic. Maybe there was some mistake. Could NI R&D please check this?

I mean time I have tested almost 20 years old SCXI 1125 module which was used for demonstration and educational purposes and has still factory calibration constants in EEPROM. When the module left the factory the output offsets on all channels and gains were below 670 µV and today they are below 22 mV. I have done this by reading the factory AI.DevScalingCoeff and AI.DevScalingCoeff after SelfCal and then calculate the corresponding output offsets (used VI is attached). I have also check this procedure by measuring the offsets with external DMM and have obtained similar results.

I have also additional common question regarding verification procedure of the calibration. Should the test limits be narrowed if the device temperature is less than ±10 °C from the device temperature at last external calibration? How is this implemented in Calibration Executive software?

Thank you,

Bojan

06-18-2018 01:42 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@Bojan

I have also additional common question regarding verification procedure of the calibration. Should the test limits be narrowed if the device temperature is less than ±10 °C from the device temperature at last external calibration? How is this implemented in Calibration Executive software?

Calexec requires the calibration environment to be 23C +/-5C for the SCXI-1125 procedure. There is no specific check of the exact temperature of the environment, so it is up to the operator to ensure the lab meets these requirements. Therefore calexec assumes the worst case scenario for temperature variation. This is common practice when calibrating devices in general. If you want to use the device within a tighter temperature tolerance, then you may need to apply guardbanding to the limits based on your own use case.

As for the actual aging of the components... I am not surprised that the warranted specification is much wider than the actual performance of your unit. Generally NI is very conservative with their warranted specifications to ensure that >95% of devices will pass these limits. Assuming a roughly gaussian distribution of performance across devices, the majority of devices would be expected to have significantly less drift than the worst case. Specifications labeled as "typical" are usually a better representation of how the majority of devices will perform.