- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

Contact Information

Country: Taiwan

Year Submitted: 2017

University: National Taiwan University (NTU)

List of Team Members (with year of graduation):

Wei-Hsi Chen(2013), Hung-Sheng Lin(2015), Yun-Meng Lin(2017), Ting-Hao Wang(2018)

Faculty Advisers: Prof. Pei-Chun Lin

Main Contact Email Address:

peichunlin@ntu.edu.tw

Project Information

Title: TurboQuad, a leg-wheel transformable robot using LabVIEW and CompactRIO

Description:

This project is aiming to create a hybrid mobile robot that can perform smooth transitions between wheeled mode and legged mode and therefore preserve the benefits of both wheel and leg.

Level of completion: fully functional

Build time: 4 years

Products:

Software:

LabVIEW, LabVIEW Real-Time Module, LabVIEW FPGA Module

Hardware:

NI cRIO-9024 Real-time controller

NI cRIO-9118 8-slot CompactRIO reconfigurable chassis

NI 9205 Analog input module

NI 9264 Analog output module

NI 9403 Bidirectional digital I/O module

NI 9401 High-speed bidirectional digital I/O module ×2

NI 9227 Current Input Module

Others:

Maxon RE30 motor ×8

Maxon Encoder ×8

Hall sensor ×8

Infrared sensor ×4

IMU ×1

Inclinometer ×1

Potentiometer ×1

The Challenge:

Developing an energy-efficient leg-wheel hybrid mobile robot that can perform smooth transitions between wheeled mode and legged mode. The robot should also be capable of driving quickly and smoothly on flat terrain and stably negotiating natural or artificial uneven terrain.

The Solution:

Using NI LabVIEW and CompactRIO with various I/O modules to rapidly integrate the mechanical, electrical and software elements of our design into a functional robot prototype and then progress to an advanced version.

Introduction

Previously in 2010, we reported on a leg-wheel hybrid robot, Quattroped, which has the advantage of both the wheels’ fast and smooth locomotion capability on flat ground and the legs’ capability on rough terrain negotiation. The novel leg-wheel transformation mechanism allowed the robot in leg or wheel morphology to be driven by the same set of actuators and supporting mechatronic system. The built-in state machines allowed the robot to have various wheeled or legged behaviors for terrain adaption and negotiation. However, the previous bi-state leg-wheel transformation mechanism required the transformation to be executed when the robot was at rest, and the discrete behavior-programming generated motion discontinuity during behavior transition. Thus, the constraints on both the mechanism side and the programming side limited the robot’s ability to perform high-speed, agile, and smooth locomotion with transition among various built-in behaviors.

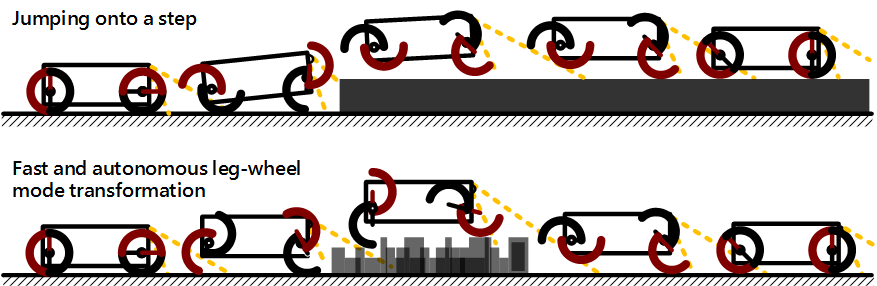

Aiming to develop the leg-wheel transformable robot with fast leg-wheel transformability for agile morphology adaptation to the largely existing hybrid environment, we reported on a new style of robot, TurboQuad, with different leg-transformation mechanisms and totally new bio-inspired behavioral exhibition and transition strategies, which overcame the limitations of the previous robot and achieved “hybrid” not only at the mechanism level but also at the behavioral level. Figure 1 shows the photos of the robot in wheeled mode and in legged mode, respectively. Figure 2 depicts the scenarios of the robot negotiating hybrid terrain: when the robot faces terrain change, it can rapidly change its behavior within one stride, similar to the gait change in animals.

|

|

Figure 1 Photos of the robot TurboQuad |

|

|

Figure 2 Illustrative scenarios where the robot adapts its morphology (i.e., wheeled or legged) to the terrain |

Mechanism

The robot has four leg-wheel modules. Each leg-wheel module is composed of two half-circle legs and can be driven to rotate and move radially with respect to the hip joint, where the motion is similar to the definition of the 2-degrees-of-freedom polar coordinates. When the legs form a circle and rotate, the robot moves like an ordinary four-wheeled vehicle, and when the legs are extended, the robot moves like a quadruped.

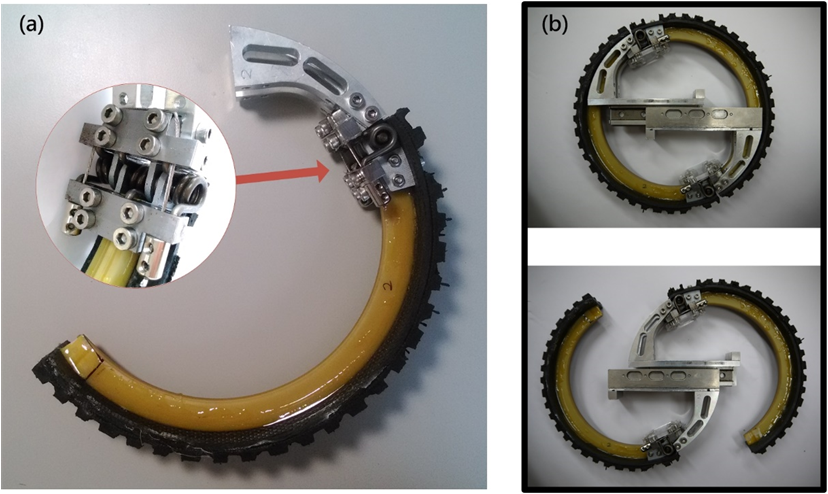

The leg-wheels of the robot can be replaced by another type of leg-wheel shown in Fig. 4. By using the passive torsion spring, the mechanism can react rapidly to external forces. In addition, by actively using only the rotational DOF, this method also reduces the loading of the DC motors.

|

|

Figure 3 Motion of the leg-wheel module |

|

|

Figure 4 (a) Torsion spring leg-wheel (b) Torsion spring leg-wheel in wheeled mode and in legged mode. |

Mechatronic system

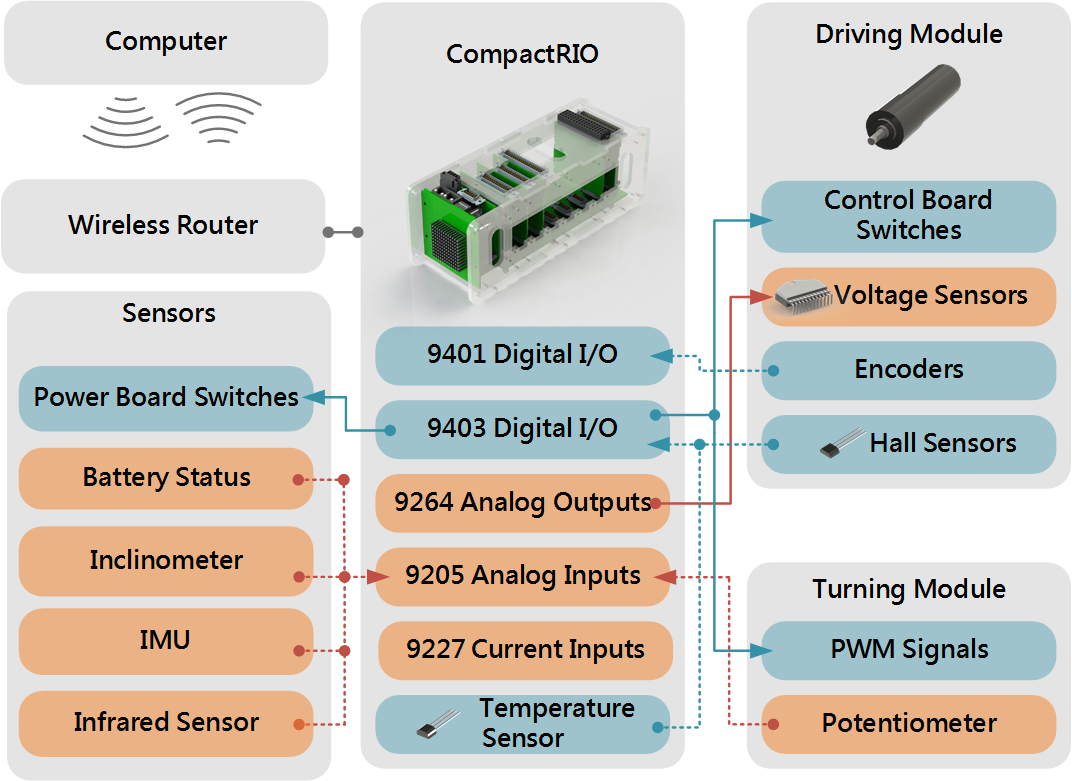

The CompactRIO cRIO-9024 and cRIO-9118 were chosen as the computation resource of the robot, owing to their robust, modular, rugged, and real-time characteristics. The greatly improved performance of the new CompactRIO in comparison with their predecessor cRIO-9014 and cRIO-9104 (installed in the old version of the robot) allows us to implement bio-inspired, high-level, and calculation-intensive control strategies for robot behavior.

On the cRIO-9118, the FPGA is used to link the real-time control system to the I/O hardware which is linked to custom motor driving boards and various feedback sensors. The FPGA makes it possible to accomplish a simple and flexible low-level control system in a short time. When high-speed computing is needed in motor position and current control, the FPGA provides a fast and powerful way to address the signal processing method and PID control. With the power the FPGA, the real-time program can be greatly simplified, reserving the computing resource for a complex high-level control system.

Six NI I/O modules are installed on the cRIO, including (1) two NI 9401 high-speed D I/O modules for receiving high-speed motor encoder signals; (2) one NI 9403 D I/O module for interfacing digital sensory inputs (i.e., hall-effect sensors, temperature sensors, etc.); (3) one NI 9205 AI module for interfacing analog sensor inputs (i.e., inclinometer, potentiometer, infrared sensor, an inertial measurement unit etc.); (4) one NI 9264 AO module for controlling DC motors and (5) one NI 9227 current input module to implement force control by current feedback. The structure of the mechatronic system of the robot is shown in Figure 5.

|

|

Figure 5 Mechatronic system of the robot |

Software structure

The LabVIEW program of the robot includes three portions: the main control program run in the microprocessor (RT), the interfacing program executed on the FPGA, and the GUI program installed on a laptop. The GUI mainly has four functions: sending high-level control commands to the robot, monitoring the robot’s health, adjusting control parameters, and data logging for further analysis.

In evaluating the performance of TurboQuad, the quantitative analysis is an important process. Owing to the changing computing resource demand in a complex real-time control system, some data points may be missed when using the traditional write to file function. In contrast, the FIFO function is a reliable way to record precise experiment data under heavy loading conditions.

Figure 6 shows the front panel and block diagram of the software.

|

|

(a) Block diagram of FPGA and RT |

|

|

(b) Front panel of RT |

|

Figure 6 LabVIEW Front panel and block diagram of the robot |

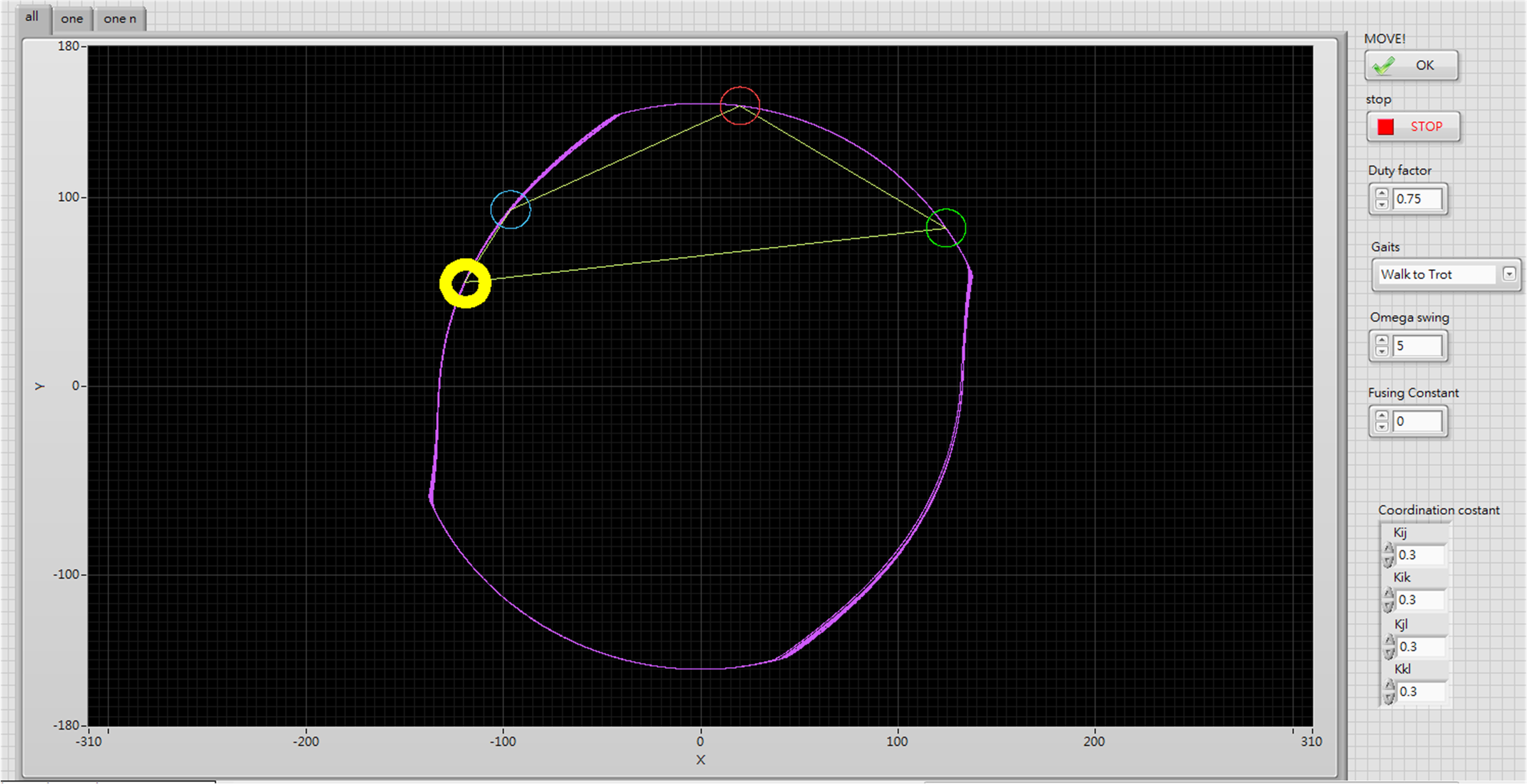

In addition, LabVIEW is also used to simulate the trajectory of the robot. For different gaits/modes of the robot, coordination of the leg-wheel should be maintained. During the development stage, the planned trajectory is first examined by the simulator before being sent directly to the robot. Figure 7 shows the trajectory simulator for the walking gait.

|

|

Figure 7 Trajectory simulator |

Bio-inspired control strategy

The theory behind the Central Pattern Generator (CPG) states that the CPG located in the spinal cord of animals can generate rhythmic neural signals without sensory inputs or accurate calculations from the brain. This neural signal is then modified according to sensory feedback signals and high-level commands to generate suitable gaits and trajectories for different terrain adaptation. In such a way, the animals can exhibit smooth gait transitions. A similar strategy is programmed into the robot.

The CPG applied to TurboQuad consists of three layers: the command layer for high-level commands like speed and gait, the mode generating layer for trajectory generation and the motion layer for motor PD control. There are four dependent oscillators for each of the four legs. Each of the oscillators is linked to its adjacent ones, which makes coordinating the positions of all legs possible. Three modes/gaits and two model-based gaits are implemented, including a high-speed wheeled mode for use on flat terrain, a stable low-speed legged walking gait for use on rough terrain, a legged trotting gait for use on medium-rough terrain and two legged pronking gaits based on R-SLIP model and SLIP models. Based on the CPG strategy, the legs-wheels in all modes/gaits are coordinated in a rhythmic manner and the mode/gait can transit rapidly and smoothly. Figure 8 demonstrates the mode/gait transition for the three modes. Figure 9 shows a pronking gait based on the R-SLIP model with torsion spring leg-wheel and a pronking gait based on the SLIP model using force control with 2-DOF mechanisms.

|

|

(a) Wheeled mode to legged walk mode |

|

|

(b) Wheeled mode to legged trot mode |

|

|

(c) Legged trot mode to legged walk mode |

|

Figure 8 Transition between different modes |

|

|

(a) Pronking gait based on R-SLIP model with torsion spring leg-wheel |

|

|

(b) Pronking gait based on SLIP model using force control with 2-DOF mechanism |

|

Figure 9 Model-based gait implementation |

In the future, we will continue focusing on control strategies with a larger variety of sensor feedback to make the robot more versatile. For example, with the addition of a vision system, the robot could perform automatic behavior switching according to different terrains. We hope that through this project we can learn more about legged robotics and make a robot that can someday be used in a wide array of applications .

Benefits of NI Hardware and Software

It is indeed a great challenge for a group of inexperienced students to design and build a complex bio-inspired robot, which generally requires knowledge in mechanical engineering, electrical engineering, computer science, and a little biology. For the BioRoLa team at National Taiwan University, which is comprised primarily of students with mechanical engineering backgrounds, a reliable, modular, easy-to-use, and well-integrated mechatronic system suitable for rapid prototyping as well as a user-friendly programming environment plays a vital role in the robot development process. We found that NI CompactRIO products and LabVIEW are the perfect solutions for us, not only because CompactRIO and LabVIEW individually serve as an ideal mechatronic system and a software program, but also because their seamless integration allows complicated hardware-software integration to be done with minimum time and effort. Thus, the students can understand the philosophy of “do engineering” of complex systems and focus on the scientific findings which incrementally improve our lives and better our world.

Nominate Your Professor

We would like to nominate Professor Pei-Chun Lin. Professor Lin offers fundamental suggestions for this project and provides a wonderful environment for students to do research in. We learned a lot from his attitude toward research in robotics, he encourages us to explore every possible option of our ideas and to learn by doing. He has supported this project for several years and makes the implementation of this robot possible. Without his enthusiasm and guidance, it wouldn’t be possible for us to complete this huge project in such a short time.