From Friday, April 19th (11:00 PM CDT) through Saturday, April 20th (2:00 PM CDT), 2024, ni.com will undergo system upgrades that may result in temporary service interruption.

We appreciate your patience as we improve our online experience.

From Friday, April 19th (11:00 PM CDT) through Saturday, April 20th (2:00 PM CDT), 2024, ni.com will undergo system upgrades that may result in temporary service interruption.

We appreciate your patience as we improve our online experience.

The customer approached TBG with the requirement to convert a manually controlled actuator test system into a software controlled automated test system. The software needed to allow the operator to control all aspects of a Parker Compax3 drive and MH series motor capable of speeds of up to 10,000 rpm.

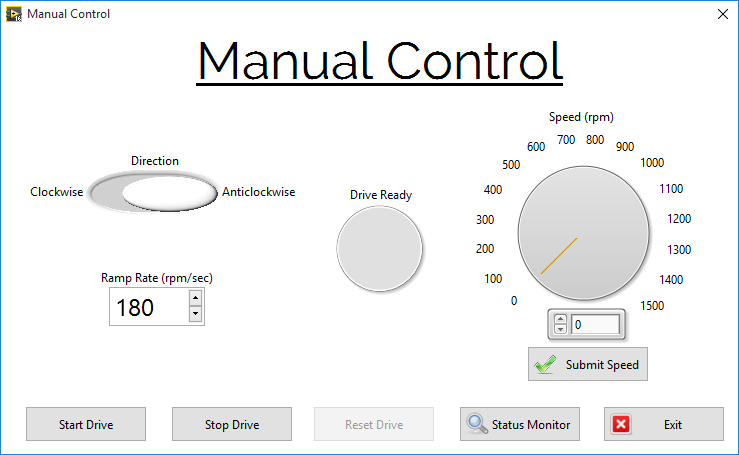

The solution by TBG Solutions is a bespoke LabVIEW application that allows for full control of the motor drive as well as a profiling application to allow for automation and sequencing of ramp rates and dwell times to fulfil the critical test specification of the UUT.

TBG created our own driver set for communication with the motor drive, of which is the first of its kind for the Compax3 series of motor drives, the ease of the Object-Oriented method of programming and the capabilities of LabVIEW’s acceptance of a HAL environment means that the software is scalable to multiple test sets and can be transferred over to other motors and drives

The customer is one of the world’s leading aerospace component manufacturers, specialising in actuator and motor systems for a range of aircraft they required a software-based solution to upgrade an existing manually controlled friction brake actuator test rig to be fully automated with an intuitive interface.

Initially the customer was told by other integrators that this would not be possible, however the experience of TBG Solutions and our capabilities gave us the confidence that this could be done and not only could we produce the software in house but also make use of our in house mechanical and electrical expertise to make changes to the inner workings of the test rig to allow for full control in software.

We were able to make use of the LabVIEW IDE and its prebuilt functions for serial RS232 communications to build a OOP based HAL for the Parker Compax3 Motor Drive, this provides flexibility and scalability for communication between multiple systems and different motors.

As mentioned, the application makes use of the OOP programming architecture this coupled with TBGs own OOP based QMH design pattern allows for a scalable application architecture where events and error handling are organised and reliable.

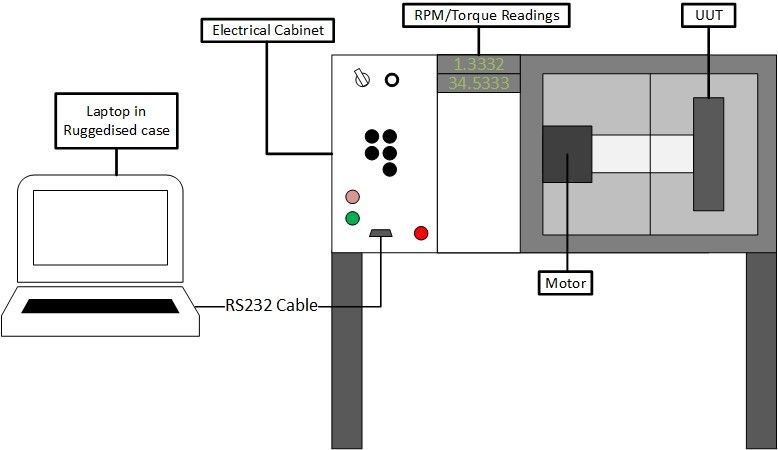

System Setup - The system is ultimately controlled by a LabVIEW based driver set sending and receiving commands to a Parker Compax3 motor drive and motor. Feedback from this motor is also displayed on COTS indicators showing the speed and torque on the shaft and UUT. The system itself connects via RS232 to a laptop within a rugged Pelican case designed and manufactured in house by TBG solutions to the highest standards. A basic system overview can be seen below.

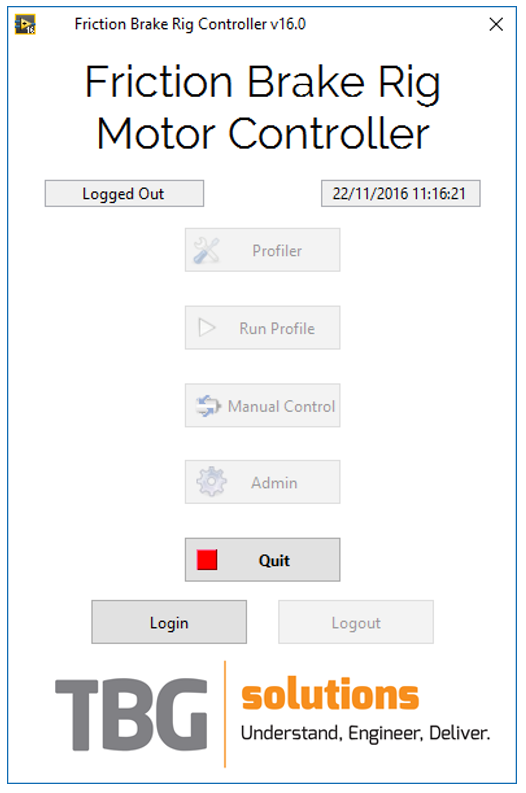

The Software Interface of the application can be split into 4 discrete parts which are:

Main Interface – This the main launcher where a user can select different screens dependent on their requirement such as the profile editor, manual control or even user management. All buttons are enabled/disabled based upon the user’s credentials (i.e. admin, engineer or operator).

Platform Based Approach Benefits - By implementing a platform based approach, Integration of NI hardware with 3rd party motors and drives was simplified using the LabVIEW environment. By having prebuilt libraries for handling serial communications meant half of the work was done in terms of TBG's custom library, this lead to reduced development time and delivery ahead of schedule compared to if we had used other software IDEs.

The use of the LabVIEW OOP capabilities means that we can create an application that not only exceeds customer expectations but also allows for a fully scalable design architecture which serves as a base foundation for further systems and other projects.

Since delivery, the system has tested thousands of units where previously they would have tested hundreds manually. The system runs daily with the customer reporting good feedback on the usability and reliability of the system, keeping them on track in terms of units tested and at the forefront of the aerospace industry.

Overall, the combination of prebuilt libraries, the capabilities of LabVIEW and the scalability of the OOP environment, TBG were provided with a base IDE that allowed for ease of integration with 3rd party devices and provide the customer with an intuitive, efficient and reliable interface whilst hitting all function specification and test requirements.

Personal

Email - jonathan.hobson@tbg-solutions.com

NI Community: JCH_26

TBG Solutions

Website: http://tbg-solutions.com/

Phone: +44 (0) 1246 819 100

Email: info@tbg-solutions.com

Address: 3A Midland Court

Barlborough Links

Chesterfield

Derbyshire

S43 4UL