From Friday, April 19th (11:00 PM CDT) through Saturday, April 20th (2:00 PM CDT), 2024, ni.com will undergo system upgrades that may result in temporary service interruption.

We appreciate your patience as we improve our online experience.

From Friday, April 19th (11:00 PM CDT) through Saturday, April 20th (2:00 PM CDT), 2024, ni.com will undergo system upgrades that may result in temporary service interruption.

We appreciate your patience as we improve our online experience.

Company: TBG Solutions

Author(s): Marcin Polaszyk

NI Product(s) Used: LabVIEW, PXI-1031, (x2) 7350 Motor Controller, UMI-7774

Industry: Security Products

Application Area: Automated Test

To develop an improved version of an existing Servo Cycle Machine (SCM) system to meet a new set of performance specifications in the door lock security industry.

Using a wide array of NI and Third Party Products a complex multi-layered solution was created that is capable of carrying out a number of accurate tests for determining the quality & lifespan of various security locks.

The customer is a provider of security products and solutions for homes and businesses in almost 130 countries across the globe. Therefore, it is a top priority to ensure that their global customer base receive the best products. Being unsatisfied with the functionality of their current SCM system, they sought out TBG Solutions, a National Instruments Gold Alliance Partner, to re-develop the system with new and improved functionality.

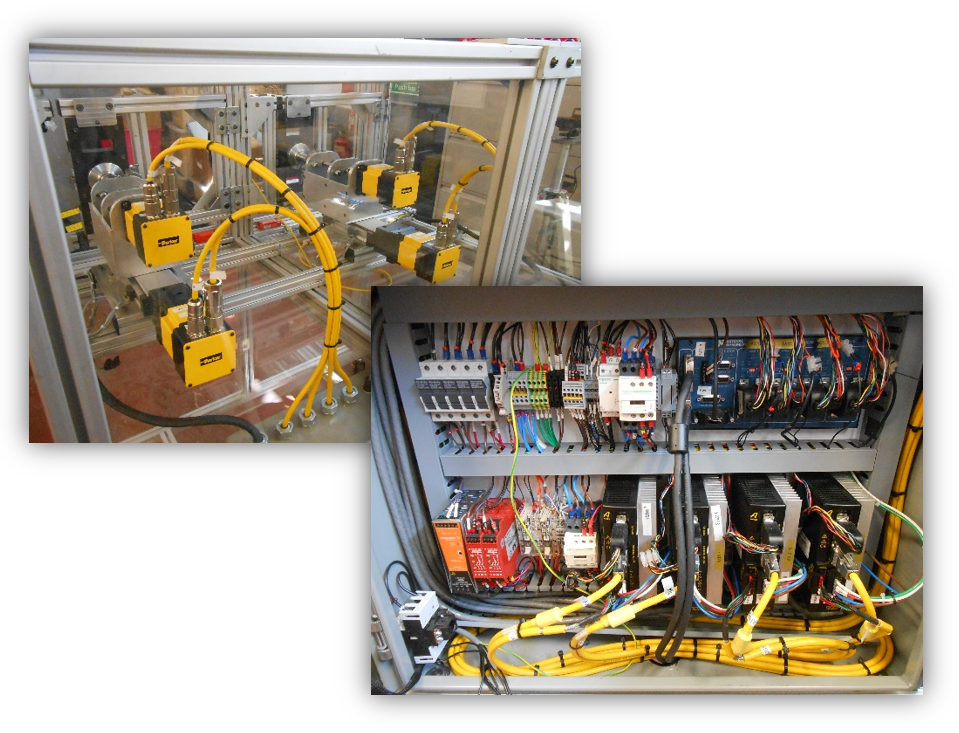

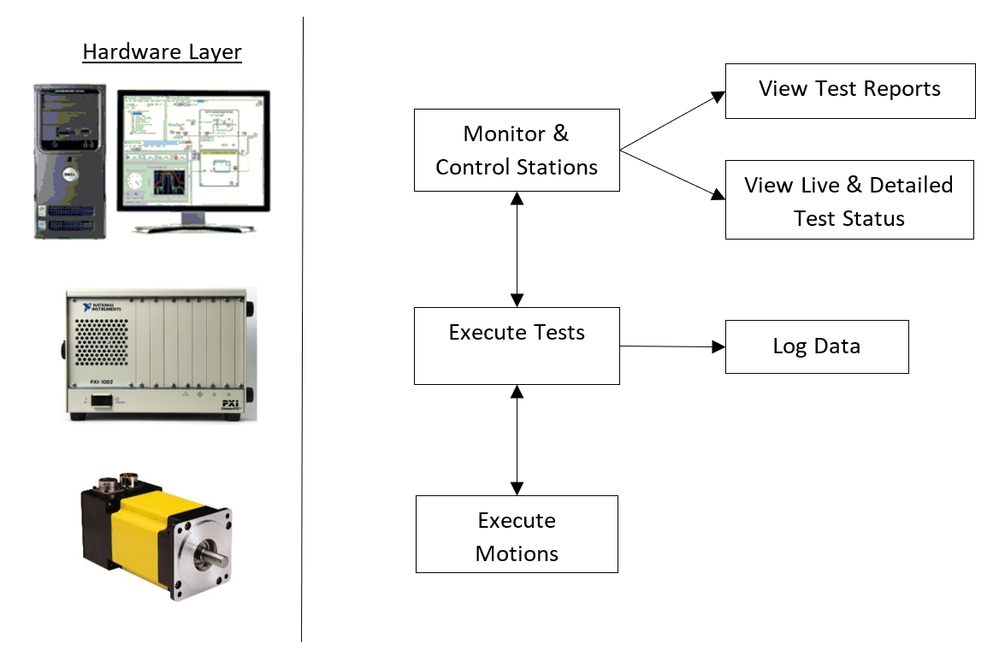

The system consists of a desktop computer running LabVIEW, a PXI-1031 Chassis, and 8 Motor Stations. The desktop computer communicates with the PXI Chassis over an Ethernet connection. The PXI Chassis holds two NI 7350 Motion Controllers, allowing it to interface with 2 cabinets (4 Motor Stations) per card (Figure 2). It performs input and output to all peripheral stations and executes test sequences while the Operator PC allows the user to interact with the system and control the stations.

Each cabinet (Figure 3) consists of an NI UMI-7774 board which interfaces with third party hardware; 4 Aries Drives and Parker Motors. The Aries Drives receive motor feedback and are responsible for controlling the BE-Series Motors. Each drive corresponds to one motor. The development of the software was carried out entirely in NI’s LabVIEW programming software and involved the use of various built-in tools which are described in the following section.

Prior to choosing NI technology, TBG Solutions looked into the PXI-like solutions offered by Aerotech as a platform for motion control. Upon further investigation, we discovered that they lacked key features which were essential in achieving the project’s full potential. Due to the lengthy nature of the tests, it was required for the solution to perform critical tasks for extended periods of time while the Operator PC is switched off; this was unachievable without a solution with a dedicated controller, such as NI’s PXI Chassis.

Upon settling with NI’s PXI platform as a base for our motion control solution, it was clear that further development using NI’s products would be easy as they offer seamless integration and extensive support, both online and over the phone. Also, this solution would accommodate for potential growth as PXI’s modularity allows easy expansion.

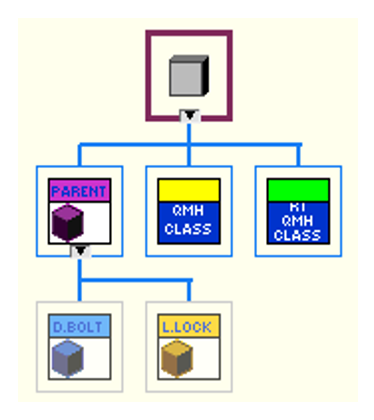

The software design (Figure 4) resembles that of the hardware as each motor station has a corresponding software-clone. This design was achieved with the use of LabVIEW’s ability to asynchronously launch VIs on the PXI Chassis running a Real-Time operating system dedicated solely to hosting the clones. Each clone is capable of executing a selected test sequence and reporting back to the main application located on the Operator PC, providing a detailed insight into test results. The communication link between the two was achieved using LabVIEW’s Network Stream protocol which allowed us to easily communicate between real time and windows based applications.

LabVIEW’s Object-Oriented Programming (OOP) functionality was used in conjunction with the asynchronous VI calls as it allowed for creating a hierarchy (Figure 5) of test sequences which could be dynamically dispatched. This enabled us to develop a generic station-clone capable of executing any implemented test sequence, significantly reducing the development time whilst improving expandability of the software as new tests & stations could be incorporated into the existing code.

Another NI Product that aided the development process was the Measurement & Automation Explorer (MAX). The ability to graphically view the motor’s step response made PID tuning more straightforward and helped to reach the perfect accuracy vs. speed balance which was essential in achieving the system’s key requirements. Moreover, the capability to propagate one axis setting to the whole Motion Controller with a single click made the configuration process less time consuming and allowed to focus on the development of the software.

The motors were controlled with NI Motion library, which eliminated the need to develop motor drivers. This made the implementation more streamlined and accommodated for potential system changes as the third party motors could be replaced without the need to modify software.

During the implementation, we encountered a problem with UMI-7774’s general-purpose digital I/O lines. After a number of correspondences, with the help of NI Engineers, we were able to debug our system and find the root of our problem. NI’s timely responses allowed us to quickly resolve this issue and resume the development; minimising the down-time and wasted resources.

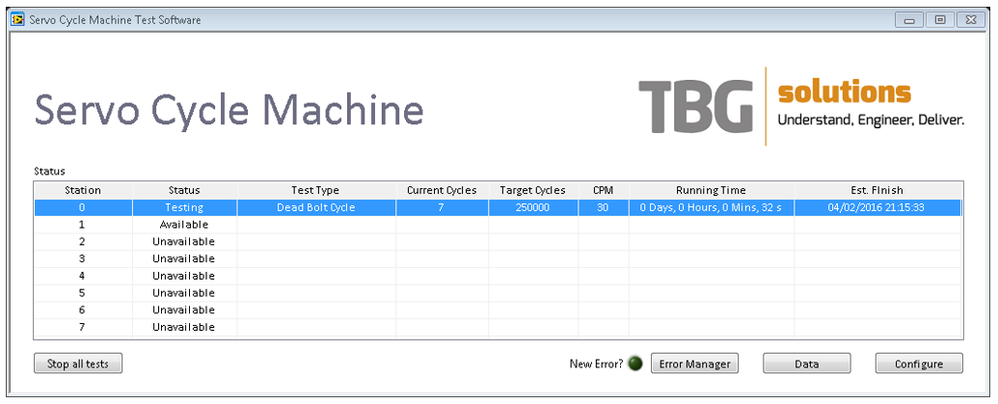

The main user interface (Figure 6) has been designed to provide a clear overview of all stations while maintaining the scalability of the software beneath it. The user can gain access to station-specific options by right clicking. A single control was used to achieve this, showing how powerful and flexible LabVIEW’s applications can really be.

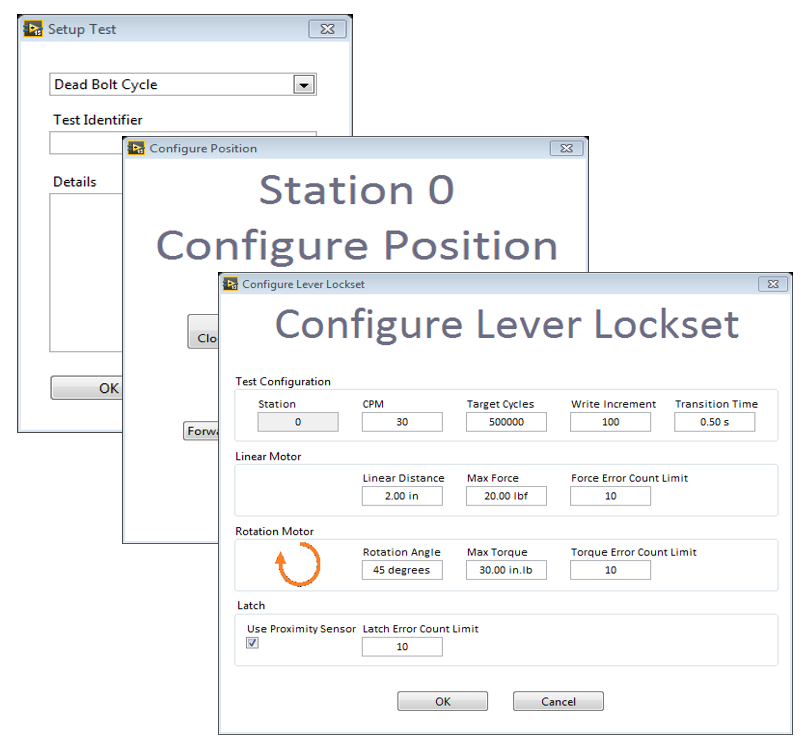

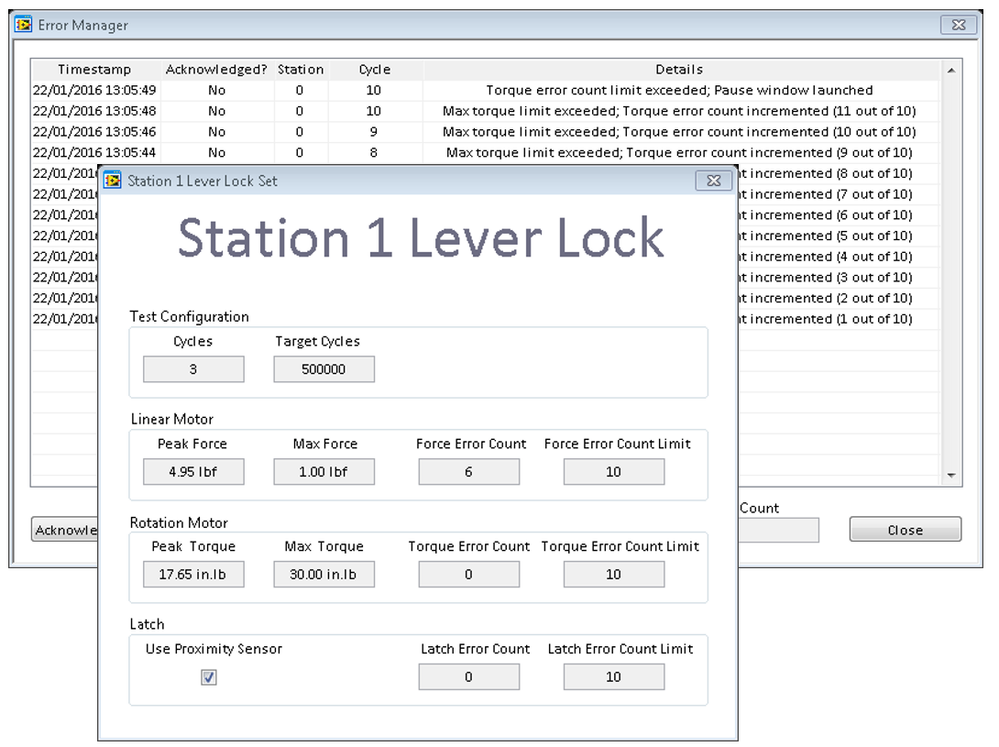

Firstly, the user can configure the test to execute a series of steps (Figure 7) during which all the test variables are set-up. LabVIEW’s support for custom controls was utilised in this process as we were able to create a more intuitive control for the ‘Direction’ variable. This tool was easy to use and is a good way of making the user interface unique and more instinctive.

Secondly, a status window (Figure 😎 can be displayed, showing all test variables while updating them in real time.

In order to achieve a solution that satisfied all our requirements, it was necessary to use a variety of products that would come together as a whole. National Instruments provided all the required components, allowing TBG Solutions to seamlessly produce a complex, multi-layered system capable of controlling any third-party drives and motors. Furthermore, with the use of previously mentioned built-in LabVIEW tools, we were able to quickly and efficiently develop the software whilst not having to sacrifice quality or functionality.

With the testing speed reaching up to 200 cycles per minute, the system provides a great platform for quicker and more reliable inspection of the security locks. Moreover, detailed test feedback is continuously available; allowing the operator to monitor and manage tests with a click of a button.

In addition to direct testing of the units, the customer has gained the ability to accumulate product quality data for analytical purposes; allowing them to ensure the quality of their products remains at a high level.

NI has again proven to be a reliable provider of tools for creating a professional solution; allowing companies like TBG Solutions and our customers to continue consistently delivering an excellent service.

Personal

Email: marcin.polaszyk@tbg-solutions.com

TBG Solutions

Website: http://tbg-solutions.com/

Phone: +44 (0) 1246 819 100

Email: info@tbg-solutions.com

Address:

3A Midland Court

Barlborough Links

Chesterfield

Derbyshire

S43 4UL