From 04:00 PM CDT – 08:00 PM CDT (09:00 PM UTC – 01:00 AM UTC) Tuesday, April 16, ni.com will undergo system upgrades that may result in temporary service interruption.

We appreciate your patience as we improve our online experience.

From 04:00 PM CDT – 08:00 PM CDT (09:00 PM UTC – 01:00 AM UTC) Tuesday, April 16, ni.com will undergo system upgrades that may result in temporary service interruption.

We appreciate your patience as we improve our online experience.

Company: TBG Solutions

Author(s): Jonathan Hobson

NI Product(s) Used: LabVIEW, cRIO 9030

Industry: Renewable Energy, R&D

Application Area: DAQ

The customer approached TBG with the requirement to remotely monitor many distributed accelerometers across a test hall used for testing 15MW wind turbine nacelles. The software was to be accessible via an intuitive HTML interface which can be accessed anywhere on the site as well as being scalable to add more sensors and easily change sensor positions and names.

The solution by TBG Solutions is a complete LabVIEW & cRIO based DAQ system, implementing cutting edge FPGA and Real-Time based code to acquire, process and log accelerometer data at a minimum of 200Hz. The code integrates complex FPGA code for acquisition and scaling as well as real time code to pipeline to TDMS based hourly log files which are buffered over a 72-hour period whilst instantly sending the data to an AJAX based web interface with multiple tabs, tables and graphs.

The customer is at the cutting edge of wind energy research, development and test and cover everything from blade technology to turbine test. The customer has have worked with TBG solutions on several projects with this project being one of latest to enable them to gain deeper insight into their test data.

Due to the scale and capabilities of the test hall, it is critical for the customer to ensure that any vibrations from their custom-built force actuated system (FAS) or the rotation of the Nacelle itself do not cause damage to the test set, Unit under test or the test hall. Therefore, the system is integral to being able to monitor the vibrations during a test and providing the customer with an indication of the vibration level, how far it is within defined hard limits and having the ability to visually see this data over time in a real-time format and also historically in the form of user editable TDMS files.

TBG were assigned the task of interfacing several accelerometers into a hardware/software combination of TBGs choice ultimately allowing the users to view the data in a HTML web interface, Inevitably the obvious choice was to implement a LabVIEW/cRIO combination.

The biggest selling point for choosing cRIO was its capability of running real time executables headlessly meaning a simple application can be networked directly from the device and data available on any PC or mobile device.

The ability to connect external media was also beneficial, over a 72-hour period the system logs over 20 Million data-points within 13GB of data, USB 3.0 connections on the 9035 allowed for seamless read/write access and allowed onboard memory to be allocated elsewhere.

The ease of integration between FPGA and Real-Time meant that time and money could be saved and used elsewhere to build up the AJAX/HTML interface of which it was critical to be intuitive and simple in interface.

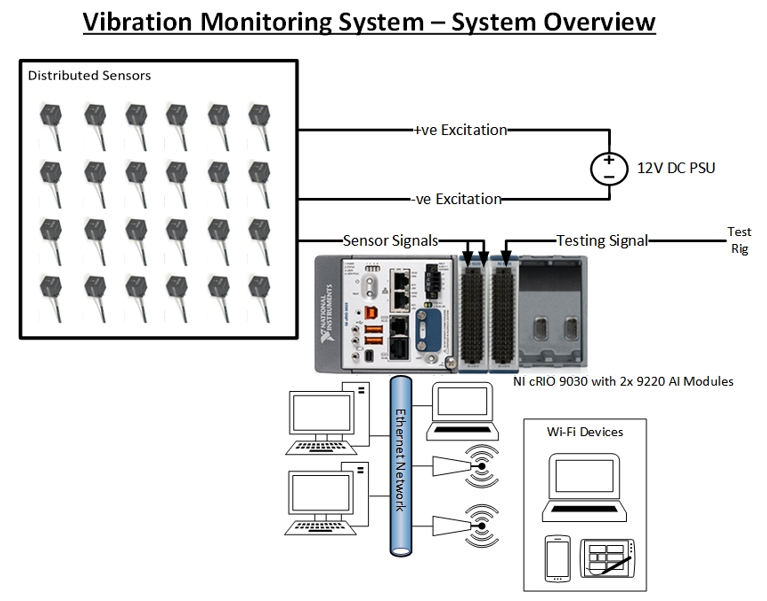

The system can be seen to have 4 discrete parts:

Overall, the system is ultimately controlled by a LabVIEW Real Time Executable which commands not only the FPGA acquisition via interrupts but is also responsible for all data passed to the web interface via XML files, this is a simple method and was critical due to the complex JavaScript based graphs and tables and their requirement for XML data inputs. The system itself is within a simple enclosure with dedicated PSU for the CRIO and accelerometer excitation, of which the accelerometers are distributed over an area roughly 100m2. The cRIO is then networked to the facility’s network allowing for ease of access from any connected devices such as tablets or mobile phones. A basic system overview can be seen in in Figure 2.

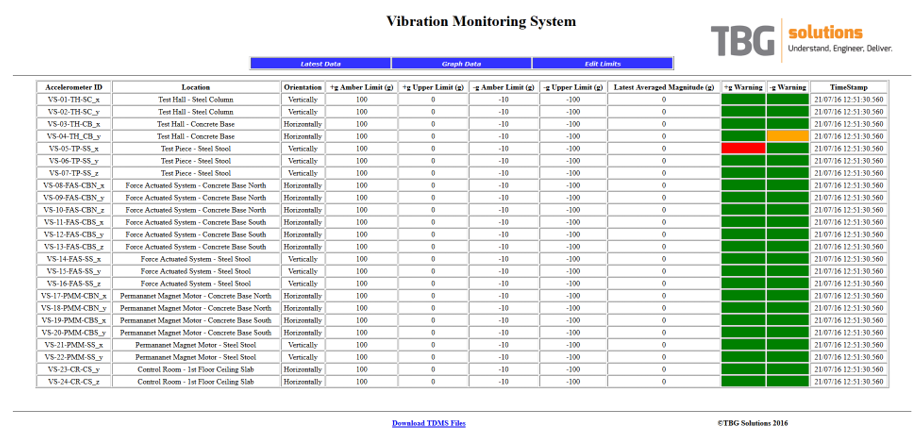

Configuration and operation of the system is done so by interaction with a web based AJAX/HTML interface. This was custom made by TBG solutions using the latest in web based graphical interfaces. The user has access to 3 screens:

Latest Data – This screen shows the latest averaged accelerometer data as seen in figure 3, updated every second via table detailing the accelerometer names, orientation, limits and values. Most importantly there is a colour coded indicator highlighting if the value is within a green, amber or red limit for +Ve and -Ve g limits.

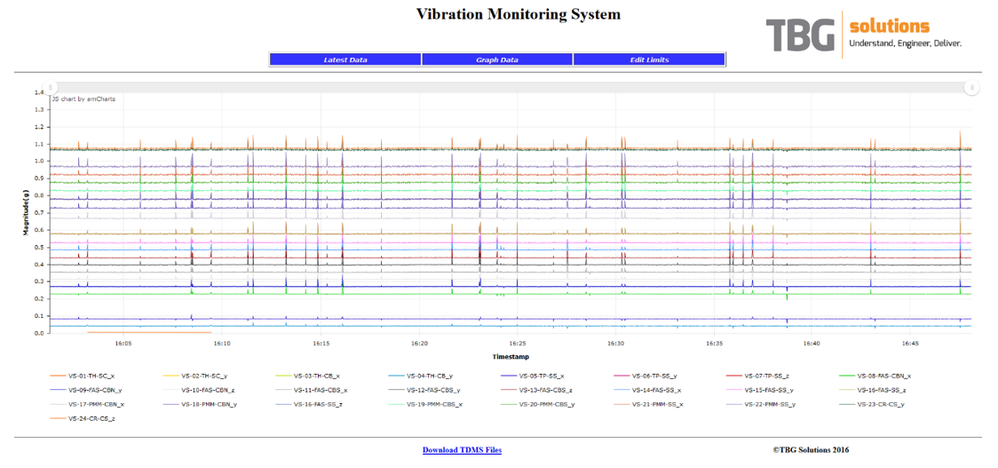

Graph Data – this screen shows averaged data over a 1 hour period for each sensor (as seen in figure 4). The data is fully zoomable and a user can isolate specific sensors to see trends or spikes in the data that low them to make critical decisions as to stop the test or not.

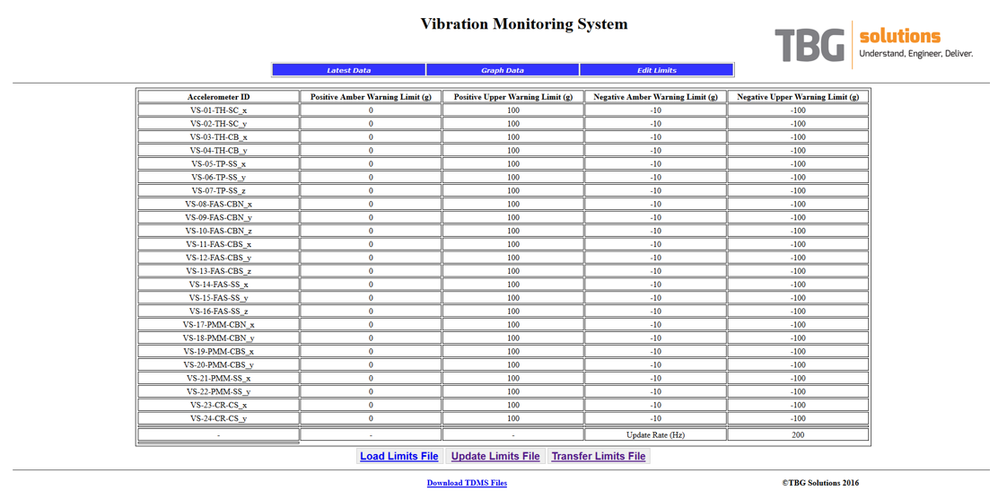

Edit Limits – This screen allows the user to pull in a defined CSV file detailing the sensor names and limits (as seen in figure 5). This can be saved and applied to change any given sensors alarm limits as well as the FPGA acquisition speed. This file seamlessly integrates with the Real-Time code running on the cRIO.

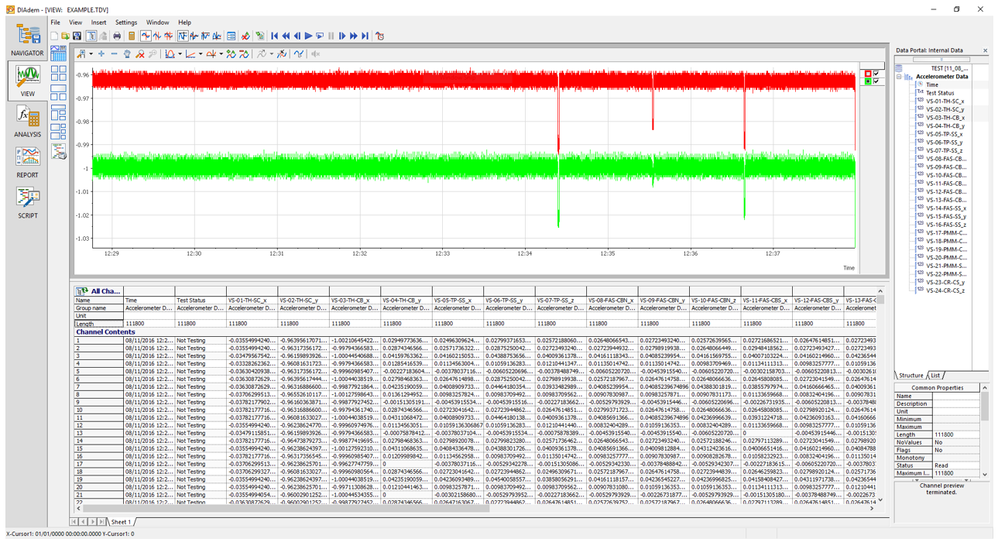

Due to the ease of integration with the TDMS file format and the depth of analysis this brings to an application, it was the go to file format for this project. Having a number of sensors acquitting at 200Hz meant that we’d need an application that would allow the customer to analyse data down to a single sample and do so in an intuitive environment such as DIAdem.

The user can easily download TDMS files from the RIO over the network and then analyse the data instantly in DIAdem as seen in figure 6. This has allowed the customer to quickly diagnose the exact point during a test that a high vibration occurs then influencing the way they optimise test to get the most out of the test set and UUT.

By implementing a platform based approach, Integration of NI hardware with existing 3rd party sensors were simplified by the use of the LabVIEW environment. By having prebuilt libraries for handling Real time communications, FPGA FIFOs and File I/O meant that system design and development time was reduced compared to development in other potential software IDEs.

The use of the LabVIEW Real-Time & FPGA toolkits with prior knowledge gained from the NI Embedded Control and Monitoring course meant an ease of development in highly complex FPGA and Real-Time communication was possible with minimal effort leading to development time being drastically reduced.

Overall, the combination of reconfigurable Real-Time and FPGA based hardware coupled with the ease of development and integration with AJAX webpages in the LabVIEW IDE provided TBG Solutions with the means to understand, engineer and deliver a turnkey solution to the customer, fitting the initial brief and specification and exceeding customer expectations.

Using LabVIEW & cRIO, we could integrate with existing hardware to produce an easy to use modern DAQ interface that is in operation 24/7 allowing the customer detailed insight into vibrations during test which in turn keeps them at the forefront of the renewable energy industry.

Author Information:

Personal

Email - jonathan.Hobson@tbg-solutions.com

NI Community: JCH_26

TBG Solutions

Website: http://tbg-solutions.com/

Phone: +44 (0) 1246 819 100

Email: info@tbg-solutions.com

Address: 3A Midland Court

Barlborough Links

Chesterfield

Derbyshire

S43 4UL