- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

Company: SYSVRA S.L

Author(s): Álvaro Salcedo and Iván Sánchez

NI Product(s) Used: Labview

Industry: Pharma, Ampoules

The Challenge

The high level of demand of the pharmaceutical industry in the manufacture of glass ampoules means that machines vision systems are required for the quality control of the final product.

Moreover, it is important not only to eject ampoules out of tolerances, but also to help make them more efficient and safe.

In addition, one of the main drawbacks is the complexity to acquire a quality image of glass or any transparent material.

The Solution

The commitment of this system is not only to eject the ampoules out of tolerances, but to act in the manufacturing process of the ampoules to correct the production and reduce the discarded raw material, thus achieve a great saving in production.

This system has been achieved by SYSVRA with the help of NI software, where our engineers have worked side by side with experts in the manufacture of ampoules to achive this.

Application Description

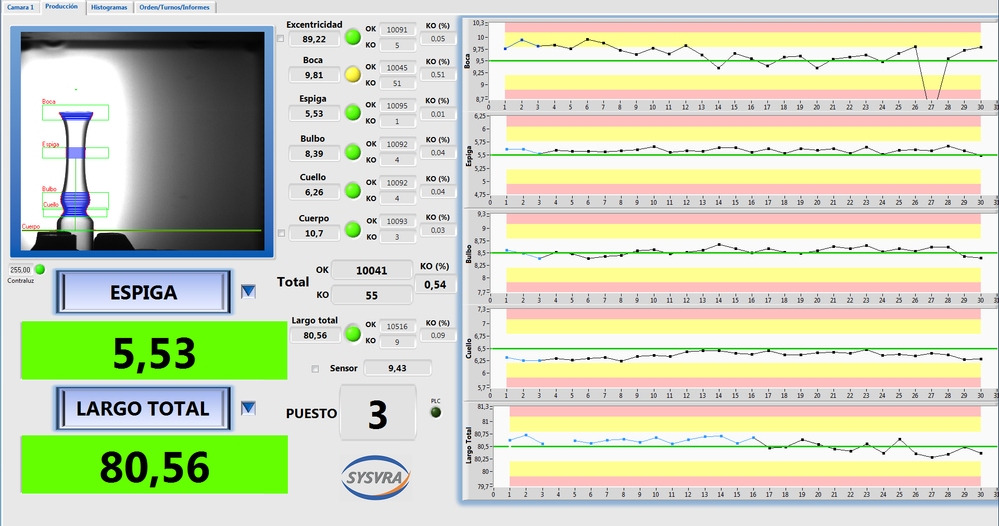

We have developed a machine vision system that performs sizing control of glass ampoules in the production process.

This system, ejects the ampoules out of tolerances chosen by the user and also helps the production machine to keep ampoules within the tolerances, acting on the burners machine. For that reason, the material saved in the production will be increased.

Moreover, the integration of this system in the vertical ampoules manufacturing machines is simple, also implementing the necessary automation to act in the manufacturing process of the product.

Characteristics

Considering the level of demand of the pharmaceutical industry in the production of ampoules, the characteristics of this system are as follows:

- 360º measurement of the different parts of the ampoule.

- Concentricity and length control of the product

- Immediate correction to the process for a better production.

- Immediate eject of the product out of tolerances.

- Real-time data visualization system and image on screen.

- Visualization of graphs and production history.

- Data storage and production reporting.

- Continue inspecting while the system is in configuration mode.

The system can work at a rate of 100 ampoules per minute.

Client Investment

Thanks to the NI software and the work of our engineers, our system, apart form beaing able to be acquired completely, is integrated with third-party hardware already installed. For that reason, the client can obtain a considerable saving in the acquisition of our system and thus minimize the investment. So, if any client has already installed cameras, PC, etc… We take advantage of that hardware, integrating only the software along with all charateristics and benefits.

All this is posible thanks to the great knowledge of the SYSVRA engineers in this sector and their collaborators, who provide the production experience.

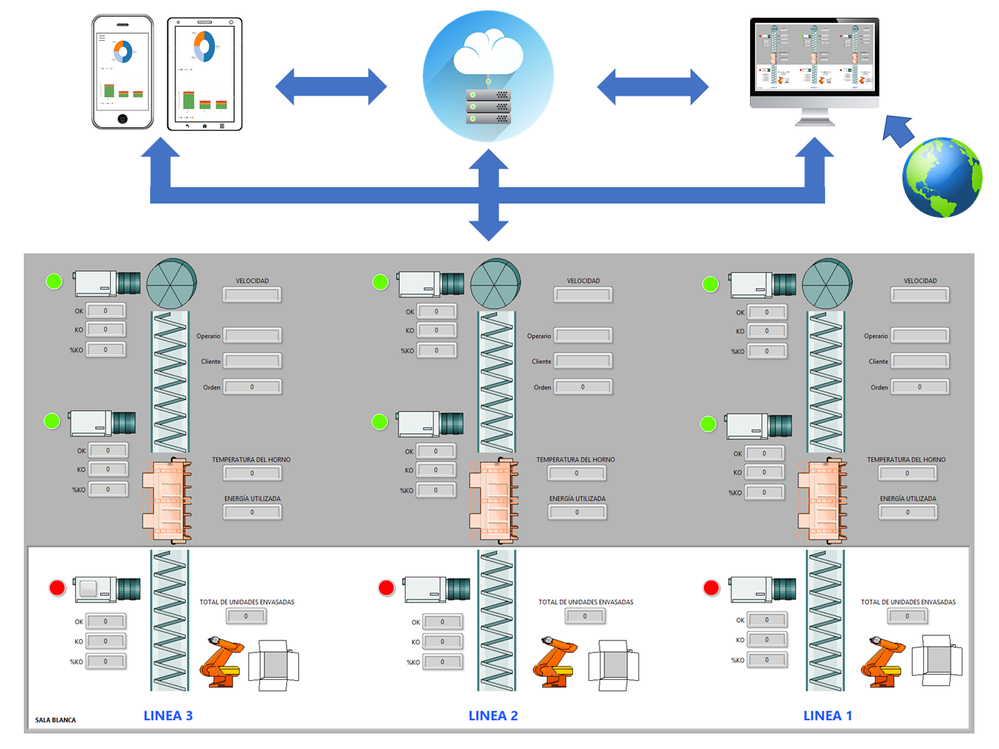

Industry 4.0

Betting on progress and wishing to bring the technology to the pharmaceutical industry to improve the performance of production processes, we are linked to the Industry 4.0 concept.

This has been a reason why we have decided to use NI software, due to the versality and easy programming for connectivity between systems.

Therefore, the developed application includes the following connectivity features, where the profitability of the factory will undoubtedly increase considerably:

- Adcquisition of dataat the factory level, storing them in the cloud.

- Consumption Control: electricity, raw material, gas… for a better understanding of costs.

- Knowledge of discarded and produced material every time, to determine the real profitability.

- Work shifts

- Centralizationof factory data to a single control point.

- Creation of production, energy and profitability reports.

- Configurable production alarms, to be able to act quickly against the problems that may arise.

- Real-timevisualization of the status machines.

- Remote accessand creation of work orders from anywhere in the world.

- Total connectivity of machines with different devices such as tablets y mobiles.

Impact

The development of this machine vision system has been a great impact on the improvement in the manufacture of glass ampoules, where the companies demanded a quality control system that would help improve the production. In addition of this, a system that would let them know how to improve their production by collecting data and accessing reports.

Conclusion

The use of NI software has made it posible to create a scalable system where it is posible to add new functionalities that the industry may require in the future, as well as a customized interface to suit the client.

It also allows us to act quickly when any incident occurs in the factory, thus providing a quality after sale service for the customers security.

Author Contact Details

SYSVRA S.L

Álvaro Salcedo – Development Engineer

alvaro.salcedo@sysvra.com

Iván Sánchez – Development Engineer

ivan.sanchez@sysvra.com