- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Communicate large number of parameters and variables between Verstand and Labview Model

Solved!01-08-2015 12:59 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

We have a dyno setup with a PXI-E chassis running Veristand 2014 and Inertia 2014. In order to enhance capabilities and timing of Veristand, I would like to use Labview models to perform tasks not possible by Veristand and Inertia. An example of this is to determine the maximum of a large number of thermocouples. Veristand has a compare funtion, but it compares only two values at a time. This makes for some lengthy and inflexible programming. Labview, on the other hand, has a function which aloows one to get the maximum of elements in an array in a single step. To use Labview I need to "send" the 50 or so thermocouples to the Labview model. In addition to the variables which need to be communicated between Veristand and Labview, I also need to present Labview with the threshold and confguration parameters. From the forums and user manuaIs understand that one has to use the connector pane in Labview and mapping in Veristand System Explorer to expose the inports and outports. The problem is that the Labview connector pane is limited to 27 I/O. How do I overcome that limitation?

BTW. I am fairly new to Labview and Versitand.

Thank you.

Richard

Solved! Go to Solution.

01-08-2015 01:19 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

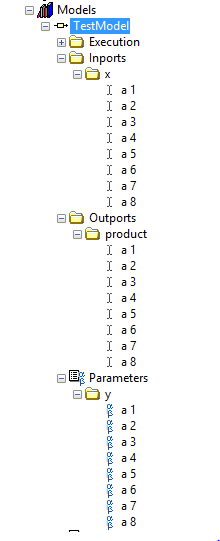

You can work around this limitation by putting your controls and indicators into clusters. Then set the cluster control to be required or recommended to specify whether the contained controls are inputs or parameters, just like normal.

National Instruments

01-08-2015 03:06 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi Richard,

Just some food for thought.

...I also need to present Labview with the threshold and confguration parameters....

A LabVIEW model may suffice for this task, but I think of a custom device. A custom device can load and change configuration parameters from System Explorer, a configuration file, any protocol, input channels (like LabVIEW model inputs), etc. A traditional LabVIEW model is limited to channel inputs for all configurable parameters. In my mind, a LabVIEW model hits usability limitations pretty quick for this task. For example, what happens when we add a parameter for all TCs? Change one TC type? Add or change to RVT or PRT? Think of all the parameters: Sensor_Type, TC_Type, Excitiation, K, a, b, c, etc. In other words, I encourage you to think about how the setup might evolve over time, and if the additional investment in a custom device may be worth the effort. The TC model(s) should probably be decimated from the PCL rate. Analogously, the custom device would probably be a slow-running async device.

-Steve K

01-08-2015 03:43 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@Jarrod:

Thank you for the help. I created a simple test model and now understand how I can use clusters for a large number of variables. Regarding the mapping process: Can one map a folder of user channels to a cluster (one-step mapping)? Alternatively, I understand one can import a mapping (text) file in System Explorer. Is this import partial or does it replace all the mapping? The reason I am asking is that, if it is partial, then I can have separate mapping files for different configurations and my final mapping can be a combination of imported mapping files.

@SteveK:

Thank you for the hint on using a Custom Device. I understand that the Custom Device will be much more powerful and can be more generic. The problem at this stage is that my limitations in programming in Labview is far gretater than Labview models' limitations in Veristand![]() . I'll definitely consider the Custom Device route once I am more provicient with LabView. Hopefully I'll be able to re-use some of the VI's I created for the LabView models.

. I'll definitely consider the Custom Device route once I am more provicient with LabView. Hopefully I'll be able to re-use some of the VI's I created for the LabView models.

Thanks

Richard