- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Connect usb-6351 to PCB Signal Conditioner, AC Coupling

Solved!01-29-2023 07:17 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hello, everyone. I typically work with load cells and the cDAQ line, which has signal-conditioning built-in. However, in this case, I have:

- USB-6351

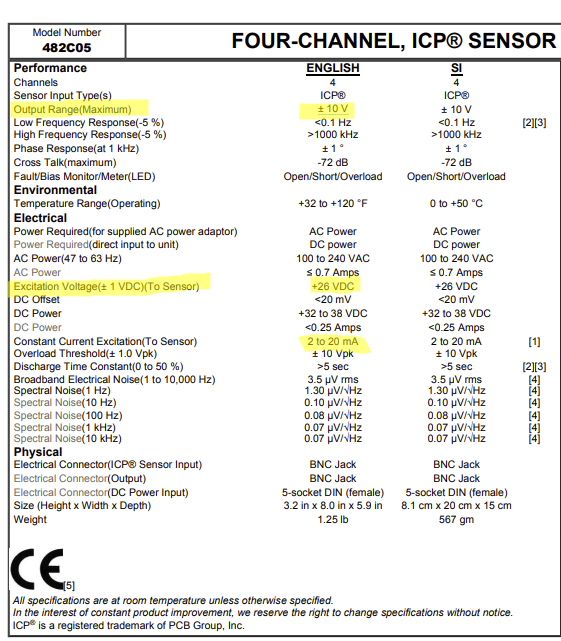

- PCB 482C05 Four-channel, IEPE Sensor Signal Conditioner

- Three accelerometers (208C05)

The accelerometers connect to the IEPE port of the signal conditioner channel, then there is an output port which outputs +/-5VDC. My original thought was that the signal conditioner was giving me a traditional DC signal, like I would get from a load cell signal conditioner. However, after a talk with PCB, the tech support agent was clear that the unit is AC coupled only. Honestly, I have only a vague understanding of AC coupling, and I'm not confident I'm connecting the device properly. PCB always wasn't very clear; I informed the agent on the phone that I was using the differential inputs because I was expecting both positive and negative voltage. The agent said he wasn't sure I should use a differential input, but then also said he wasn't sure I should tie one side of the output to ground. There isn't really a third option.

Currently, I have the signal conditioner connected as follows:

USB-6351 PCB 482C05

1 ai0 + ch1 out +

2 ai0 - ch1 out -

4 ai1 + ch2 out +

5 ai1 - ch2 out -

7 ai2 + ch3 out +

8 ai2 - ch3 out -

I created a custom scale in NI MAX to convert the voltage range (+/-5VDC) to the force range (+/-1000 pounds) and named it "PCB208C04."

Then, from python, I add an AI voltage channel:

Solved! Go to Solution.

01-29-2023 07:56 PM - edited 01-29-2023 07:57 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

The foremost issue is that USB-6351 is not well suited for the job. You need a DSA card to interface with accelerometers.

A quick lesson on why a DSA instead of a DAQ,

- Vibration and Sound signals are AC in nature

- "relative" amplitude and frequency content are of utmost importance in these applications

- These vibration or sound signals have a high dynamic range (signals are very small and next moment very large)

- DAQ is designed for higher DC accuracy and not for AC

- ADCs used in DAQ are of low bitness - typically 16-bit

- The dynamic range of 16-bit ADC is less and you usually need to switch ranges to measure small and large signals with good resolution and accuracy

- DSA uses 24-bit ADC and hence a very large dynamic range (110dB+) - mostly you don't need to switch ranges

- DSA instruments even come with IEPE excitation (you don't need an external signal conditioner)

- DSA instruments' front end has the option to switch between AC and DC coupling options

- DSA instruments are meant to present the frequency content very well (so you can rely on FFTs on these signals captured)

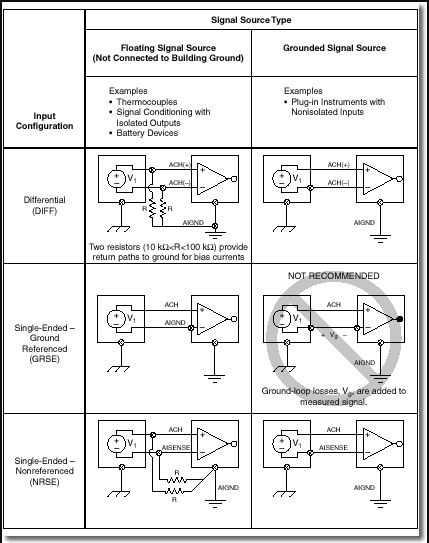

Now, to address your connection question, depending on where your PCB 482C05 gets its power, you can consider it a grounded or floating differential signal and connect as per this article - https://www.ni.com/en-us/support/documentation/supplemental/06/grounding-considerations---intermedia...

https://www.ni.com/en-us/innovations/white-papers/10/dynamic-signal-acquisition-fundamentals.html

Soliton Technologies

New to the forum? Please read community guidelines and how to ask smart questions

Only two ways to appreciate someone who spent their free time to reply/answer your question - give them Kudos or mark their reply as the answer/solution.

Finding it hard to source NI hardware? Try NI Trading Post

01-30-2023 06:20 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

First off, thank you for your comprehensive response.

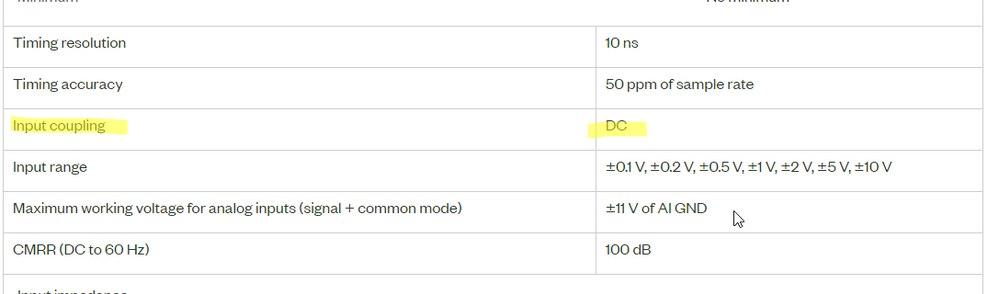

So, you're saying the USB-6351 can't do AC coupling?

I understand what you're saying about hardware limitations, and this isn't the hardware I would have chosen, but it's the hardware they've given me and is currently the standard for this test I have to make work. I'm stuck with it for now. I wonder if setting up a custom voltage channel would be better instead. Set the excitation source to 5V, the excitation voltage to 1V (that's the spec on the 482C). The data I get that way seems more reasonable, although I don't really have a way of confirming.

>> depending on where your PCB 482C05 gets its power,

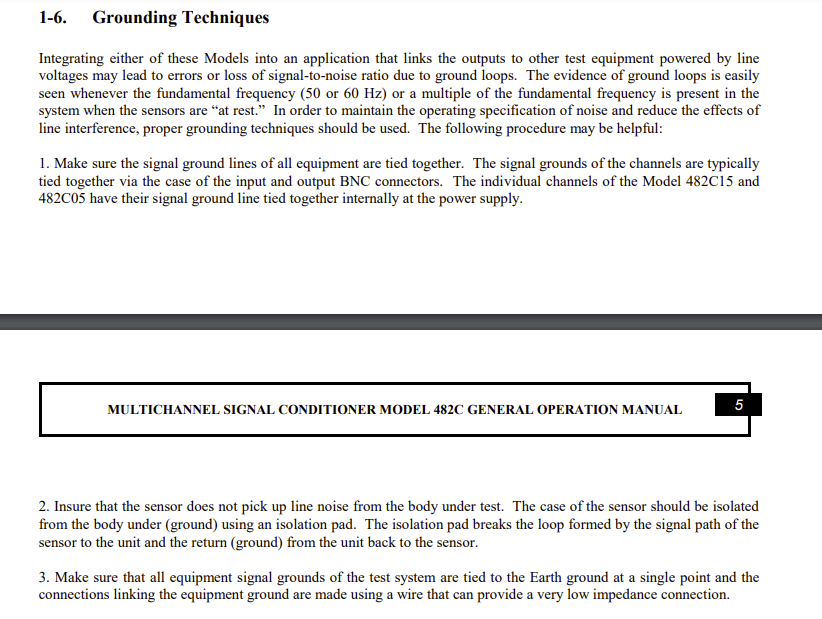

It gets it from a wall-wart that puts out + and - 32 VDC and does not appear to have any connection to earth ground.

01-30-2023 08:28 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

USB-6351 can only do DC coupling - but it does not matter in your application as your signal conditioner already blocked DC and outputs only AC

If you're limited to 6351, it is fine, it will work but not the best/appropriate. Choose an appropriate voltage range for the DAQ to digitize the signal properly, either internal or external.

Nothing much you need to do from the DAQ side, treat the signal like a voltage input. Ensure the grounding is proper, it looks like the signals are referenced to ground (BNC outer terminal) and choose an input configuration and grounding appropriately.

To test whether your setup works properly, I would suggest attaching the accelerometer to a small geared DC motor and run it at a constant speed, now you should be able to pick up that motor rpm in the output of the accelerometer. Check if PCB suggests any simple way to test the setup.

Soliton Technologies

New to the forum? Please read community guidelines and how to ask smart questions

Only two ways to appreciate someone who spent their free time to reply/answer your question - give them Kudos or mark their reply as the answer/solution.

Finding it hard to source NI hardware? Try NI Trading Post

01-30-2023 12:14 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Thank you so much. This has been very helpful.

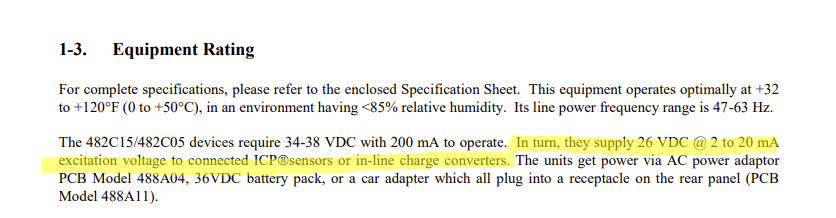

My only remaining question is how to configure the input. The Signal Conditioner is exciting the force sensor at 1VDC. Will I see that on the output side and need to compensate, or do I just use input as a regular voltage channel.

Sorry for the basic questions. Normally, I use cDAQ cards specifically made for IEPE sensors, and all of this happens magically.

Thanks!

01-30-2023 09:08 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

On the DAQmx side, configure an Analog Voltage Input task with a 10V range (choose a range based on actual observations) with a custom scale to translate to your physical units.

The reason I suggest 10V is that the datasheet states a max +/-10V output signal from the conditioner (depends on the gain and actual signal from the sensor), adjust it later based on your observations.

The sensor is powered by a constant current (that you set between 2 and 20mA) with compliance set at 26V +/-1V DC (not 1V signal as you assumed, it was rather the accuracy of the DC bias of IEPE)

Soliton Technologies

New to the forum? Please read community guidelines and how to ask smart questions

Only two ways to appreciate someone who spent their free time to reply/answer your question - give them Kudos or mark their reply as the answer/solution.

Finding it hard to source NI hardware? Try NI Trading Post