- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Detecting Presense of Screw Using Vision Builder

03-08-2019 11:14 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi. I have several screw types I am trying to detect, and would like some help. Seems very simple at first, but it turns out I am having some difficulty. I have tried matching pattern, detecting objects, measure intensity, inspect contours, find circular edge, geometric matching, etc. I even tried reversing the logic where Vision Builder searches for no presence of the screws, but nothing seems to work.

I believe the issue is similarities in contrast/color between the screws and the surroundings, including the screw hole, since the depth is only about 1/8 inch. I would get intermittent results, especially from board to board.

In this project, I have success in inspecting ~150 parts (including many other screws) using the methods I described above, but these screws prove quite challenging.

I've attached a screen shot for your reference.

I would greatly appreciate any suggestions you may have.

Thank you.

03-09-2019 05:11 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi,

It is very difficult to suggest something without knowing the entire setup and parts. If you can add some more pictures of the part with screw and without screw, I can better analyse the situation.

But as a general advise you can use the Vision Assistant tools in order to extract the required features easier in your application. Sometimes you may need to process the image with different parameters for different inspections in the same image, like board, solders, screws etc.

I can see the cross shape on the screw is shining more than the surroundings. Probably after some enhancements and analysing many pictures with and without screws, you may find the standard deviation of the area(maybe using measure intensity) differs for these parts.

You can also take advantage of combined analysis for the difficult applications. If one function does not give you the exact solution, use more than one function like you did, and try to calculate the result based on the combined analysis of all.

03-11-2019 07:25 AM - edited 03-11-2019 07:28 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi sevincom,

Thank you for the suggestion. I also tried using the Vision Assistant tools by enhancing images but to no avail. I don't consider myself an advanced user, so I have not yet taken advantage of Vision Builders full capability.

Attached is the image with the screws. Unfortunately the lighting is not as uniform as I would like it, so I am trying to work with what is presented to me.

I am open to any suggestions you may have.

Thanks again.

03-11-2019 09:40 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Here is one with screw. Sorry, for the separate responses as there is a file size restriction.

03-11-2019 01:52 PM - edited 03-11-2019 01:53 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi,

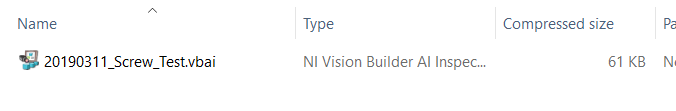

Attached you can see a simple test I made without any coordinate system or detailed processing tools.

You can see there are differences of pixel intensities between the screws and holes. But it is dependent to your whole imaging setup. For example, the bottom right area is really bright when having the screw and very dark when without screw. On the other hand, central right one is just reverse, so I arranged the settings based on that.

I can say you are right, if you acquired both images with same reference and imaging setup, there is a huge deviation which we do not want. You need to test with a lot of variations and different images in order to see if this approximation works well, not only two images.

I hope this will help you.

03-11-2019 02:34 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi sevincom,

Thank you for your help. I will look at your implementation.

03-15-2019 07:20 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi sevicom,

Would you have an example of this in Vision Builder instead of LabVIEW?

Thank you.

03-15-2019 12:23 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

It is already a VBAI inspection file. The version is 2015 f1.