From Friday, April 19th (11:00 PM CDT) through Saturday, April 20th (2:00 PM CDT), 2024, ni.com will undergo system upgrades that may result in temporary service interruption.

We appreciate your patience as we improve our online experience.

From Friday, April 19th (11:00 PM CDT) through Saturday, April 20th (2:00 PM CDT), 2024, ni.com will undergo system upgrades that may result in temporary service interruption.

We appreciate your patience as we improve our online experience.

03-06-2012 09:45 AM

Vasco,

Related to this profile generation, I think you are complicating the process here. I recode your profile generation below according to the picture you have on the block diagram.

The profile works the following way:

1. Convert the Table (string) to array. The Fract/Exp String To Number accepts matrices of strings, making it easy to convert

2. Obtain the X and Y as arrays, since we need this input for the Lookup Table

3. Reduce the Step Size of the function to 0.01. This is necessary to obtain the 'sharp' profile you have

4. Use the Reminder to repeat the time over and over ( I used 6 s for that)

If you could look into that code, it should should provide you the "repeating sequence" that you'd like to have in Control and Simulation. We will consider adding this functionality in the future.

03-06-2012 03:49 PM

HI!

Realy works well ... I have tested andcame to the conclusionwhat are the rules to use it right ...

It is important that the maximum or last value in the Table(x-value) is the same value for the simulation time .... and also is the same value as simualtion time the y value at Quotient/reminder ... e.g. last value in the graph is 5 (as biggest) ...

Maybe my question was not answered about the step profil, which is very common/frequent in the dynamic ("overshoot") analysis .... certain time at certain speed level and the sharp change .... how can lookup table follow such working profile accurately ?! I have also posted proposed solution how to build the step profile, which has to be accurately followed by the dynamic system .... like in thediagra below ...

And just a comment about the posted VI files ... save please Your VI for posts in older versions (like 2009) .... You have version 11 ...

03-06-2012 04:53 PM

Hi!

I have looked in Your reply... works, but have limited success ...

Both graphs shoud display same results (locations and amplitudes) .... time (X) and curve values (Y) should be same as in the resulting tables ... both graphs are the same, with same results and have scaling factor 1 ... only the scale for Y is set on 0,35 ...

The transfer function for the model is the same, but written in 2 different ways ... to check the validity of own results ....

Thanks!

03-07-2012 08:54 AM

To obtain the sharp corners, you just need to repeat the values with the same time. The look-up table with linear interpolation should take care of it. For example, your 'doublet' profile should be:

X - Y

0 400

0 600

0.03 600

0.03 200

0.06 200

0.06 400

The code I already posted should take care of it.

03-07-2012 08:58 AM

Vasco,

When I said "don't change multiplier of charts", this is what I mean:

Your charts have this properties changed from 1 and this will give your the results you can't understand. Please edit the charts and use offset =0 and multiplier=1. That should make your results from Location and Amplitude match the chart.

03-07-2012 04:44 PM

Hi!

Now both solutions run perfectly .... but how you then make "envelope" curve which "sits" on maximum peaks of curve ?!

This is the criteria of damping ....xy graph interpolated and then combined with the resulting graph below ... ![]()

Thanks!

03-08-2012 11:38 AM

Please open and see this example:

examples\Control and Simulation\Control Design\Classical Control Design\CDEx PID with Constraints.vi

It has the features that you'd need to create an envelop.

03-09-2012 05:00 PM

Hi!

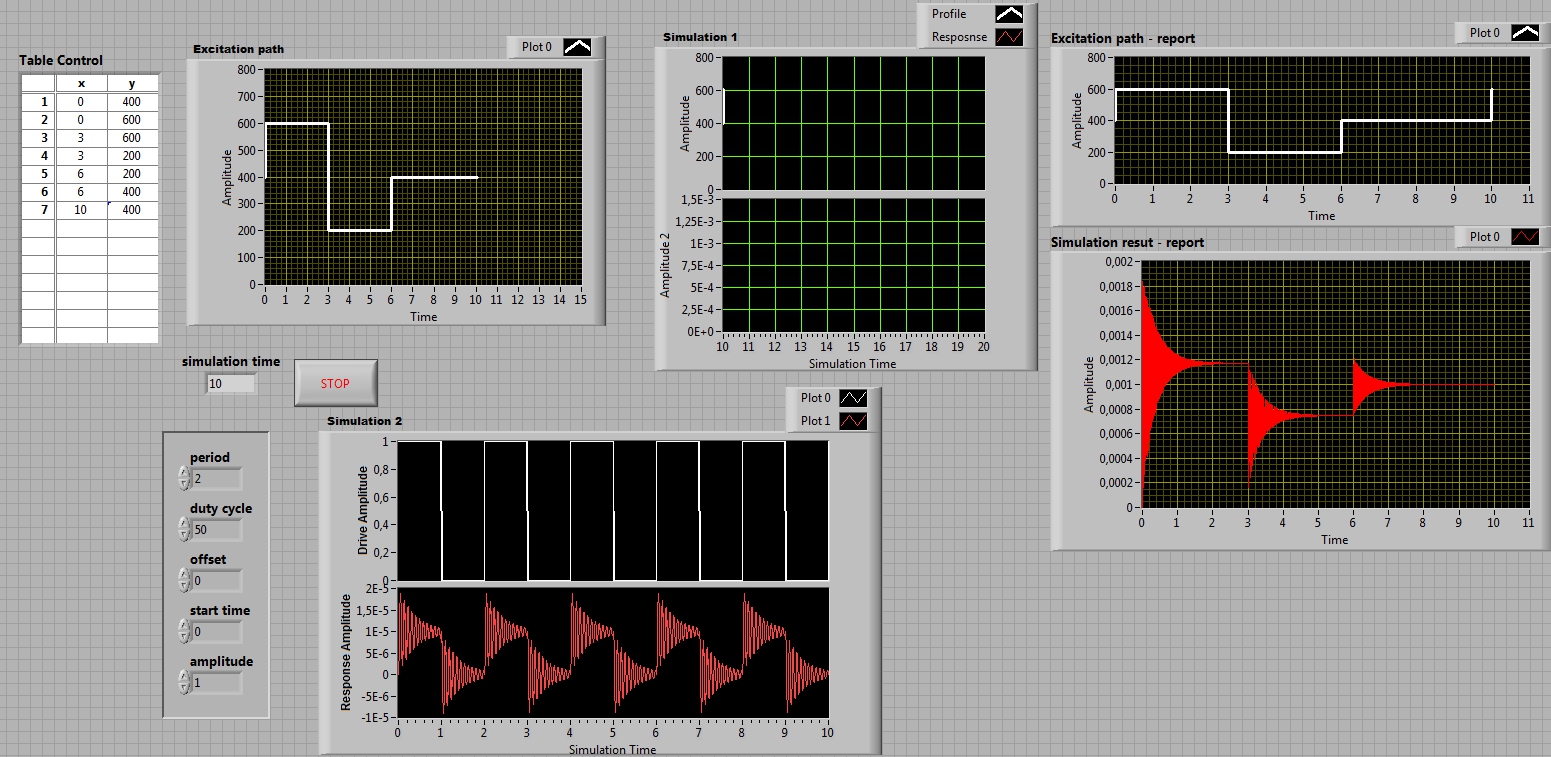

I have made a step ahead ... step stimulus is applied with the mass damper (SDOF) system ... this iscompared with the pulse excitation ...

I have difficulty to present the data on the graph ... response on each sequence of ecitation ... not only on part of signal but the whole ...

You have idea ?!

Thanks !

03-12-2012 11:23 PM

Hi VASCO-1,

It's good to see that you're making progress with your application! With regards to your question about displaying the system response on the waveform chart, you simply need to increase the chart history length. To do this, go to the front panel and right click on the inside of the chart of interest (not on the axes), and then select "Chart History Length". I changed the length to 2000 for your bottom chart ("Simulation 2", Response Amplitude) and this was sufficient to display the entire signal before the chart began to scroll (see below). For more information on this, and the caveats associated with increasing chart history length, please take a look at this article: http://zone.ni.com/reference/en-XX/help/371361H-01/lvconcepts/customizing_graphs_and_charts/.

03-13-2012 04:15 PM

Hi Joseph!

I have run the simulation 2 according to Your guidelines ... it's OK.

On the other hand ... the upper simulation has 2 failures :

1.) the graph with excitation path and response (Simulation 1) - "disapear" immeadiately after the simulation (10 seconds);

2.) at the resulting path appears additinal step (10 600), which is unintetional added ?!

I hope this would be final solution step for me, before I start with real model data.... ![]()

Thanks again and best regards!!

Vasco