- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Possible causes for loss of pressure in pressure measurement

11-12-2019 10:41 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

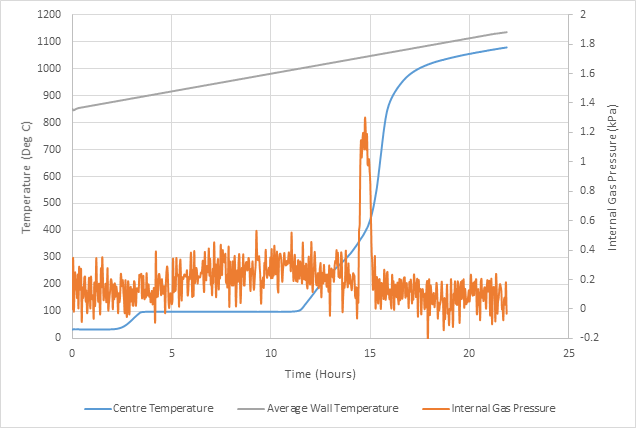

I have been having some issues with the pressure reading coming out of my cRIO (9063). Basically, at lower pressures (0 - 0.4 kPa) the readings I get match pretty well with our old system (Versadec). Once we get the pressure peak we are looking for, the pressure peak I am getting from the cRIO system is half the pressure being read by the Versadec. Not only this but instead of a nice, clean peak as we would expect in our tests, the peaks are broad and jagged. There is quite a lot of noise in our signal (harmonic resonance in the test environment) but I would not expect it to affect the signal to this extent.

The transducers are rated to 400 kPa so they shouldn't they aren't even close to their limit. Output for the tranducers is 0-10A, input module is 0-10A (NI-9201). It seems to read pressure fine when we apply pressure using a bellows, but we are still working on a way to calibrate the measurement, so are not 100% on what should be read. Any suggestions on what could be causing the discrepancy? I have included a couple of plots for comparison.

11-13-2019 05:32 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@Celnurien wrote:

Output for the tranducers is 0-10A, input module is 0-10A (NI-9201).

0-10V? or 4-20mA? Never heard of 0-10A input\outputs.

11-13-2019 06:28 AM - edited 11-13-2019 06:32 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Are you sure the "noise" is "harmonic resonance"? What kind of resonant frequency? Have you tried adding any anti-aliasing? I noticed the very long time scale of your time plot. I don't know your sample rate, but even a resonant frequency I'd normally consider very low might be showing aliasing artifacts that look like random-ish noise.

I also don't know anything about your "Versadec" system. Are you reading the same pressure transducer signal with the 2 systems?

As to the peak amplitude, are you really sure about your scaling? The place where they seem to match is way down in the realm of 0.1% of full scale, not a very meaningful area to try to match things up. It's unlikely the pressure transducers are accurate to better than 0.1%.

That leaves the peak width. That part is simply a mystery to me, I don't have any particular questions or theories (other than if the two graphs were from two distinct pressurization events. In which case, many other aspects of this troubleshooting exercise are affected too.)

-Kevin P

11-13-2019 06:35 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@Kevin_Price wrote:

That leaves the peak width. That part is simply a mystery to me, I don't have any particular questions or theories (other than if the two graphs were from two distinct pressurization events. In which case, many other aspects of this troubleshooting exercise are affected too.)

If the old system somehow (HW and\or SW) averages samples (moving or not), I think it will make the noise lower, and the peak narrower.

11-13-2019 07:01 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

wiebe@CARYA wrote:

@Kevin_Price wrote:

That leaves the peak width. That part is simply a mystery to me, I don't have any particular questions or theories (other than if the two graphs were from two distinct pressurization events. In which case, many other aspects of this troubleshooting exercise are affected too.)

If the old system somehow (HW and\or SW) averages samples (moving or not), I think it will make the noise lower, and the peak narrower.

I agree. That was my suspicion as well. Also, if the input signal really is 0-10 A (as wiebe said, this would be highly unusual) instead of 0 - 10 V then the external circuit to convert Amps to Volts could be noisy. Additionally, are you sure that the 9201 is the right card for your application. I'm not overly familiar with this card but it appears to be a low-end module. Finally, a look at your code could help with troubleshooting.

11-13-2019 07:33 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

The odd thing to me was that it was both narrower *AND* higher amplitude, which didn't seem to fit the symptom of a moving average. Anyway, just idle speculation at the moment until the OP fills in more details.

-Kevin P

11-13-2019 07:53 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@Kevin_Price wrote:

The odd thing to me was that it was both narrower *AND* higher amplitude, which didn't seem to fit the symptom of a moving average. Anyway, just idle speculation at the moment until the OP fills in more details.

-Kevin P

I agree with this also. I am under the assumption that the calibration is also incorrect.

11-13-2019 08:17 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Averaging a sine wave results in a phase shift and lower amplitude.

Obviously, more things could be wrong.

11-13-2019 09:36 AM - edited 11-13-2019 09:37 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Since the NI-9201 has a +/-10V input, presumably "0-10A" is a typo. As has been pointed out, 0.4 kPa into a 400 kPa transducer is only 0.1% of full scale, probably outside of the accuracy spec of the transducer. Also, the NI-9201 has 12 bit resolution with a +/-10V signal so only 11 bits for 0-10V, so with a 400 kPa transducer the resolution is only 0.2 kPa. Basically, your resolution isn't adequate to get accurate measurements of signals that small. The graph shows smaller variations than that so presumably there's some averaging going on.

11-13-2019 04:50 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Sorry, definitely a typo. Should be Amps.