- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Is the Verification Procedure subsection of the NI 4071 Calibration Procedure Correct?

06-10-2013 12:29 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

A) Steps 1 through 6 indicates to make a resistance measurement for the 100 mV, >10 G-ohm mode with the input shorted and save the result.

B) Steps 7 through 8 indicates to make a resistance measurement for the 100 mV, =10 M-ohm mode with the input shorted and save the result.

C) Steps 9 through 10 indicates to make a resistance measurement for the 100 mV, >10 G-ohm mode with the input shorted. Then subtract this result from the value stored in 'A' above and compare it to the offset limits in Table 20.

i) With a the exception of a brief temporary reconfiguration to perform 'B', the measurement in 'A' is identical to the measurement in 'C'. Subtracting the result in 'C' from the result in 'A' results in one sample of measurement noise.

ii) Table 20 contains the maximum allowable offset limits for a 24 hour period and a 2 year period.

iii) Comparing one sample of measurement noise as instructed in 'C' to Table 20 seems meaningless.

Am I missing something?

06-11-2013 11:52 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi, can you please elaborate a little bit on your specific question. Correct me if I'm wrong but it seems that your concern is if the Verification Procedures are relevant? Table 20 shows the values expected from a calibrated device if the measurement taken is not near these values you can take different routes depending on the outcome (calibrate again, repair...?). If you believe there is room for improvement, I will happily take the feedback.

06-11-2013 11:59 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

If you take the time to read and comprehend my post and you will see my point. The procedure has errors.

06-11-2013 03:55 PM - edited 06-11-2013 03:57 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi Ed,

To ensure that you are getting the best measurements possible with your device, every measurement you take in the 100 mV range when verifying the DC Voltage functionality of the 4071 uses offset nulling. Read through this link for a quick description of Offset Nulling.

Steps 1 through 8 tell the user to short the input of the DMM and take a reading for both of the input resistance settings. The procedure tells the user to record these values as the 100 mV >10 GOhm mode offset and the 100 mV 10 MOhm mode offset. These are the two values that will be used to perform offset nulling for every measurement taken in the 100 mV range.

From step 9 forward, you are going through Table 21, setting the calibrator to the value in the Calibrator Amplitude column and verifying that the DMM measurement falls within the range specified. The first few test points require you to apply 0 V to the input using the shorting bar. Because you are working in the 100 mV range, you subtract the previously measured offsets from your measurement.

If you look ahead to the steps that involve the calibrator (step 29), you'll see that the procedure has you apply 90 mV from the calibrator and then subtract the offset values that you measured in steps 1-8.

I hope that this clarifies your question. If not, we can discuss the procedure further.

Good luck with the calibration!

PS - There is a specific forum for DMM-related issues here. Please post any future DMM issues in this location.

Jared R.

Precision DC Product Support Engineer

National Instruments

06-11-2013 04:54 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

I see your point if steps have different measured inputs. However, Steps 10 definitely says to subtract two identical measurements and then derive a conclusion from Table 20 that is not applicable.

The shorting Bar is added in Step 1 and isn't removed until Step 27 in the procedure that I am trying to use. We are talking about the "Verification Procedure" part of the "NI PXI-4071 Calibration Procedure" aren't we?

06-13-2013 06:15 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi Ed,

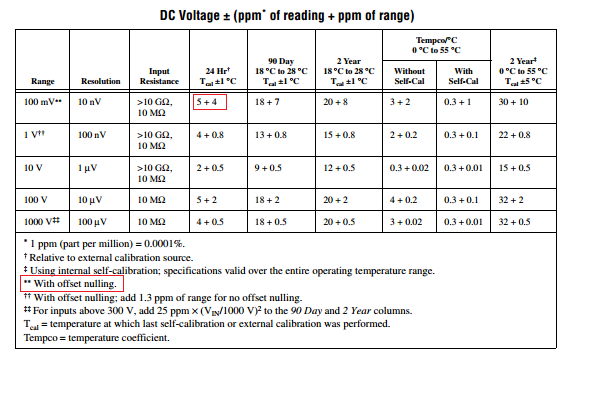

We are talking about the same calibration procedure. The spec that we are verifying in step 10 and step 12 is enclosed in the red box in the image below:

Because the test point in step 10 and 12 is 0 V, the 24-hour limit calculation is as follows:

DC Voltage ± (ppm of reading +ppm of range)

0 V ± ( 0 V * 0.000005 + 0.100 V * 0.000004) = ± 0.4 uV

You'll also see that the double-asterisk underneath the specs states that the limits in the 100 mV range assume that the measurement is taken using offset nulling.

Therefore, verifying that the DMM is within the bounds of its specifications when taking a 0 V measurement in the 100 mV range requires you to take a 0 V measurement (with the shorting bar), subtract the previously calculated null value, and compare your reading to the limits in table 20 (calculated above).

You are welcome to calculate the limits for additional testpoints if you feel that additional verification is necessary. For example, if you set your calibrator to 5 mV, take a measurement with the 4071, and subtract the initially calculated offset voltage your measurement should fall within 5 mV ± 0.425 uV. Here is the calculation: 0.005±(0.005*0.000005+0.100*0.000004) .

Let me know if you have any additional questions about the procedure.

Regards,

Jared R.

Precision DC Product Support Engineer

National Instruments