From Friday, April 19th (11:00 PM CDT) through Saturday, April 20th (2:00 PM CDT), 2024, ni.com will undergo system upgrades that may result in temporary service interruption.

We appreciate your patience as we improve our online experience.

From Friday, April 19th (11:00 PM CDT) through Saturday, April 20th (2:00 PM CDT), 2024, ni.com will undergo system upgrades that may result in temporary service interruption.

We appreciate your patience as we improve our online experience.

10-02-2021 05:46 AM

I have an ADXL355 accelerometer module, and I use NI myrio to read data through I2C.

It's a pity that I don't know much about digital logic and data conversion. How can I convert the data read by I2C into an acceleration value (decimal)?

I provide an ARDUINO SPI sample code (not written by me).

Thanks everyone for your help!!

-------------------------------------------------------------------------------------------------------------------

Solved! Go to Solution.

10-02-2021 03:21 PM - edited 10-02-2021 07:59 PM

So you get three bytes for each axis and they just need to be masked, shifted, combined and cast exactly as described.

Can you attach a simple Vi containing default data in the indicators and a description what values you expect?

(Run you VI get data in the indicators. "menu...edit..make current values default", save VI under a new name and attach it here)

(I assume with "decimal" you mean a numeric datatype, right? What is the purpose of your shift registers? can't you just wire the indicators right after the read functions? Your stop button will not work because it is outside the while loop (dataflow!). What is the desired loop rate? Don't you want 9 bytes instead of 7? etc. Have you done some basic tutorials yet?)

10-02-2021 10:16 PM - edited 10-02-2021 10:18 PM

Thank you very much for your reply~

Sorry, I have been operating labview for 3 years, but I am not very familiar with communication.

I have attached VI. The data in it represents that the Z axis lies flat on the ground, which should be approximately equal to 0.98G.

Q.Your stop button will not work because it is outside the while loop (dataflow!).

A.I'm sorry I accidentally pulled it out of the loop

Q.I assume with "decimal" you mean a numeric datatype

A.Yes, that’s right, just like the data read in VI, I want to convert it to G, for example 0.98G

Q.What is the desired loop rate?

A. I set the sampling rate of ADXL355 to 125HZ. I am not sure how fast the loop should be

so as not to miss the data.

Q.What is the purpose of your shift registers? can't you just wire the indicators right after the read functions?

A.My idea is if I use a shift register, so I can ensure that the data of Z1, Z2, and Z3 can be read at the same time in the next loop.

Q.Don't you want 9 bytes instead of 7? etc. Have you done some basic tutorials yet?

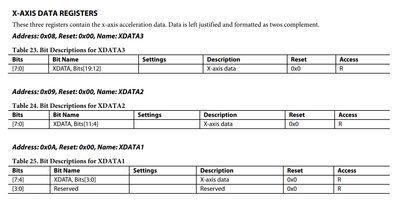

A.I'm sorry, I don't understand~In the data table, XYZ axis data contains (axis data3)7:0 , (axis data2)7:0 , (axis data1) 7:4 . Or I am mistaken about the relationship between Bit and bytes?

10-03-2021 11:33 AM

You have a lot to learn, not only about LabVIEW, but about your Chip and how it works with I²C (I'm more familiar with SPI, myself ...). Some comments:

Bob Schor

10-03-2021 12:23 PM

@koukileo wrote:

Q.What is the purpose of your shift registers? can't you just wire the indicators right after the read functions?

A.My idea is if I use a shift register, so I can ensure that the data of Z1, Z2, and Z3 can be read at the same time in the next loop.

That makes so little sense. They are obviously read sequentially at different times with the order determined by the error wire. All your "construct" does is ensure that they display at the same time, which could be achieved equally well by other means if really needed. If all three are inputs to a subVI, that will automatically wait until all data is present.

Sorry, I don't have your subVIs and drivers. For now it seems your main problem is to convert the bytes to data. I'll have a look....

10-03-2021 10:05 PM - edited 10-03-2021 10:07 PM

This is the conversion code I found in the community, but it should be closer to 0.95G, isn't it?

The graph on the right is about 0.95G measured by the accelerometer onboard myrio.

I store about 3 seconds of data in ROW DATA for your convenience. Thank you~

10-03-2021 10:33 PM

What is the problem? I hope you realize that I cannot see the extremely tiny print on your picture. I assume that you might have forgotten about "scaling" the data, and are concerned that the data you are getting from I²C isn't 0.95 (units of "g"), but is possibly an n-bit Integer (possibly signed or unsigned). Somewhere in the Data Sheets you should find values called something like "Gain" and "Bias" (or "Offset") that will let you translate the (I'm assuming "integer") values from the Accelerometer Chip into Acceleration (in uniits of "g").

Bob Schor

10-03-2021 11:16 PM

Thank you for your reply, I will try to find the conversion method in the data sheet and the data read by I2C. Sorry, I asked the question first without thinking first~

10-04-2021 10:41 AM

@koukileo wrote:

This is the conversion code I found in the community

Well, if you found it "in the community", a link would help, because the code in the picture has nothing to do with the code you have attached. Can you give us the link to the above code?

In any case, that "conversion" shown in the picture is pure Rube Goldberg. I am 100% sure it can be done with 10% of the code, nothing green, and very little orange, and the size of a postage stamp. 😄

10-04-2021 01:28 PM

@altenbach wrote:

In any case, that "conversion" shown in the picture is pure Rube Goldberg. I am 100% sure it can be done with 10% of the code, nothing green, and very little orange, and the size of a postage stamp. 😄

Indeed. This is the actually needed code for all 3 axes to implement the functionality as contained in the INO file.