- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

Country: United Kingdom

Year Submitted: 2018

University: University of Southampton

List of Team Members (with year of graduation):

- Christopher Charalambous, 2018

- Junaid Mahomed, 2018

Gayan Kahatota Liyanage, 2018 - Jin Teh, 2018

Guillaume Henry, 2018 - Thomas Parker, 2018

Faculty Advisers:

- Prof. Andrew Cruden

- Dr Lindsay-Marie Armstrong

Main Contact Email Address: tjp1g13@soton.ac.uk

Project Information:

Title: Naeah- 4WD Electrically Assisted Handcycle

The design and construction of a bespoke vehicle, enabling amputees to access remote mountainous areas. The handcycle will be used by adventurer and quadruple amputee Alex Lewis, for a fundraising trip to Ras Dashen, Ethiopia, in 2019.

Project Coverage on BBC News

Products:

- NI Compact-RIO 9063 controller

- NI 9401 Digital IO module

- NI 9221 Analogue voltage input module

- NI 9381 Multifunction IO module

- NI LabVIEW 2017 SP1, FPGA and Real-time modules

The Challenge:

For many of us, one of the great joys in life is the ability to explore the wilderness. This could be a short trek in the local National Park or a longer expedition in one of the world’s wilderness areas. Either way, it is something that is not generally open to those whose mobility is constrained.

Our aim is to build a power assisted handcycle that will enable mobility impaired people to access, explore and enjoy our National Parks and the wilderness areas of our planet on a fully independent basis.

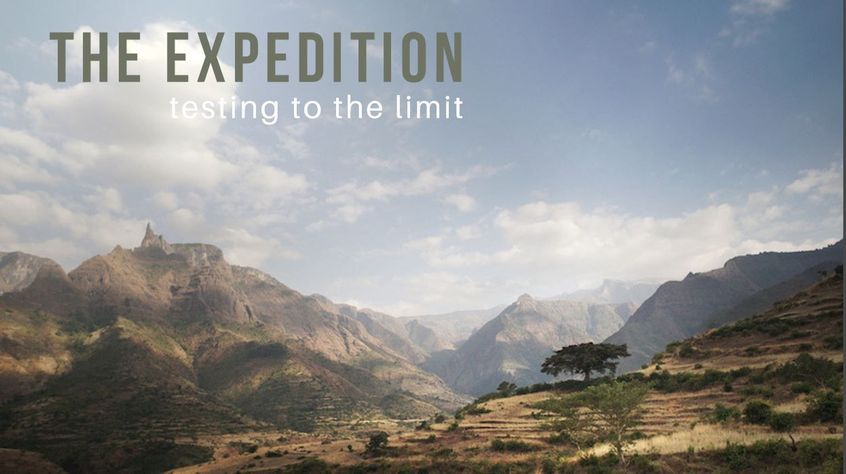

The handcycle will be tested in an expedition involving two multiple amputees to ascend Ras Dashen, the tallest mountain in Ethiopia.

Alex Lewis is determined to undertake an expedition to Ras Dashen, Ethiopia's highest mountain at 4,500 m. He will be joined by Emebet Dires, a local student and wheelchair basketball player. Together, they hope to raise awareness and funds to help develop wheelchair manufacture in Ethiopia. The country has a large number of amputees who lack access to even basic wheelchairs, which impairs their opportunities to continue going about their daily lives.

The handcycles to be used for the expedition require the following capabilities:

- Travelling over rough tracks comfortably and safely;

- Performing on steep gradients using eletric assistance;

- Driving (power-split) for at least 8 hours per day;

- Operating self-sufficiently, as only 30% of the population have mains electricity;

- Ease of repair with only basic tools and materials;

- Being controlled with only simple movements of prosthetic arms;

The Solution:

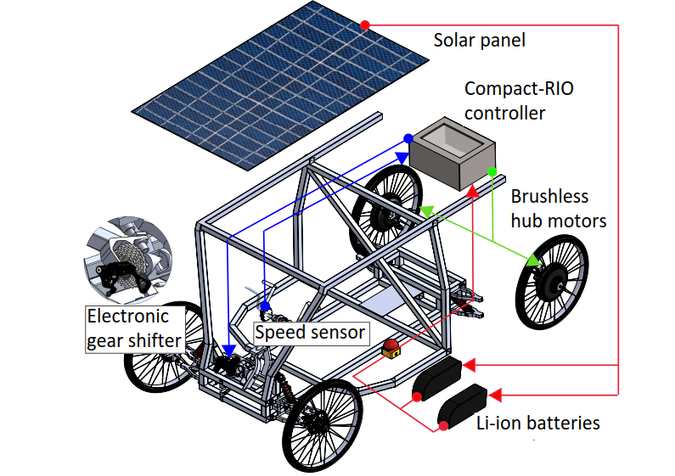

The NI Compact-RIO forms a central interface between all elements of the system - as described in more detail in the next section.

Mechanically, the completed handcycle consists of a welded aluminium body frame, with double wishbone suspension allowing all wheels to displace independently. A roll cage protects the rider in the event of a crash, and also supports the solar panel (which has the bonus advantage of protecting the rider from sun and rain). The off-road capability is supplemented by treaded tyres, disc brakes and a 4-point seatbelt. The team and their creation are shown below.

Steering is achieved using an innovative mechanism, which combines a chain drive and universal joints. Together, these allow the rider to steer whilst still powering the cranks - especially useful as Alex's prosthetics are clipped to the cranks when riding. The brake cables are also connected to this shaft via a one-way clutch bearing - to apply the brakes the rider simply rotates the cranks backwards.

The electrical system elements are shown in the following image. Whilst the front wheels are driven by hand power, the rear wheels use 1000 W brushless hub motors from a Cyclotricity E-bike kit. These provide ample torque for the steepest mountain trails. Some modifications were needed to make them suitable for our 4-wheeled design - The motor on the left has been reversed and both motors use a common throttle input. The motors and control system run from twin Li-ion batteries, each providing 12 Ah at 48 V. These are charged from a 250 W solar panel when outdoors in the sun, allowing the cycle to continue riding after a midday break. When not riding, a 12 V automotove socket is provided for charging phones, GPS trackers or cameras. All of the control system is housed inside a unit with an IP66 rating to protect against dust and water.

Powered by LabVIEW:

From the early stages of the design process, the C-RIO platform was attractive due to its customisable nature, and readily available support both online and within the University.

We chose the Compact-RIO 9063 controller as our application does not require especially high sample frequencies or extra connectivity, but resistance to vibration, varying moisture levels and temperatures. To this end, all of our C-series modules also have the conformal coating for moisture protection. The C-series modules are connected according to the attached schematic, and used as follows:

- The NI 9401 Analogue input module measures the crank input speed from two reed switches and magnets on the crankshaft. Mounting the switches in quadrature allows the crank direction to be determined. This is necessary to avoid running the motors whilst braking!

- An NI 9381 Multifunction module is used to control the speed. One analogue output pin is connected to both bruhsless motor controllers, with its voltage between 1-4 V depending on the desired speed. For safety, a maximum speed and assistance level are inserted.

- Two of the 9381's digital outputs shift the gears up and down via a Shimano 11-speed electronic derailleur (via transistors to the Shimano CAN bus node), allowing the rider to maintain a comfortable arm speed and input force over a range of ground speeds. A case structure is used to determine when to shift, and accounts for the change in gear ratio.

- Ancillary functions from the 9381 include a battery charger control relay, and buzzer to indicate the system's status.

- Our NI 9221 Voltage measurement module (upto 60 V) measures the available voltage from the solar panel and batteries. This will be used to incorporate a VI for 'Eco-mode', reducing the power output to ensure the cycle can keep moving for longer without depleting the battery.

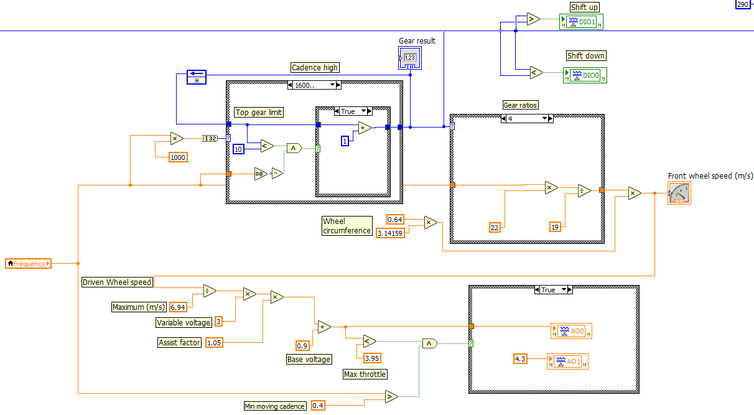

Developing the VI using LabVIEW allowed the team to bench-test each of these functions individually on-screen, before assembling the final circuits and fine tuning. It was then very simple to incorporate each of these into a single VI, and replace manual switches with inputs from the hardware. The current working version of our VI is attached below. The following image shows the block diagram which controls the handcycle's speed and gear ratio in response to the rider's crank speed.

Section of the main VI for processing crank speed. The appropriate gear is selected to ensure Alex is pushing at a comfortable speed, and a corresponding voltage is output to the brushless speed controllers.

Going forward, LabVIEW will allow the team to quickly adjust parameters such as the acceleration and crank speed range during testing. Naturally, to prove the functionality at first the top speed and assistance level have been decreased for safety.

Construction and Testing

Design work began in October, and the team of 6 have averaged around 20 hours per week developing and assembling the cycle. We're currently working on some last-minute mechanical improvements, like tensioning the chain and making sure the suspension and steering work smoothly.

The present version of the prototype is ready for Alpha testing in the South Downs at the beginning of June, to verify that it is safe for Alex to ride himself and identify improvements to be made. A team of University interns will continue with the project during the summer - upgrading the current version to a field-ready handcycle, and assembling a second for Emebet.

In February 2019, we hope that our Naeah handcycle will enable Emebet and Alex to reach the summit of Ras Dashen, in a 10 day expedition through the Simien mountains. This will involve travelling over steep and varied terrain that will test the handcycles, and their riders, to their limits on the roof of Africa. It is a seemingly impossible task for two amputees to ascend a 4,550m mountain, but in attempting this challenge Emebet and Alex aim to prove that anything is possible. It is hoped that the expedition will provide an inspiration for anyone who has a desire to achieve, but is nervous of failure.

Additional revisions

The team has a list of further work that is necessary to really make the handcycle perform in the mountains.

Mechanical Design:

- CNC mill the final suspension parts from a single billet - this will improve the tolerances and and improve strength compared to the current bolted assembly.

- Replace the disc brakes with a hydraulic version to improve performance on long descents.

VI programming:

- Replace the reed switches with a commercially available quadrature encoder, giving more precise speed measurements. A moving average filter could also help the handcycle run more smoothly.

- Use a wheel speed sensor and closed loop to better control the throttle voltage. This would make riding more intuitive.

- Better understand the batteries' performance and control the speed to optimize battery life.

- Incorporate a tilt switch, to allow a hill start assistance function.

Useful Links

- The Wild Wheelchairs Project - Website

- Donate to this Amazing Cause - Virgin Money Giving

Additional Media Coverage:

BBC National News - Wild Wheelchairs Project

Extract of Simon Ratigan's film with a description of the Wild Wheelchairs Project.

Video Produced by the Ethiopian Embassy

Alex Lewis Featured on Channel 5 News

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Wow! Wow! Wow! You guys are engineering heroes! Keep up the amazing work - and good luck with the ascent of Ras Dashen in Ethiopia!

Senior Marketing Engineer, National Instruments

Connect on LinkedIn: https://www.linkedin.com/in/richard-roberts-4176a27b/