- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

How NI Helped Cardiff Racing Make Formula Student History

How NI Helped Cardiff Racing Make Formula Student History

Country: UK

Year Submitted: 2017

University: Cardiff University

List of Team Members (with year of graduation): James Willis (2017), Shabaj Ahmed (2017), Roberto Sesia (2018)

Faculty Advisers: Mark Eaton

Main Contact Email Address: willisjc@cardiff.ac.uk

Summary.

NI technology, sponsorship and support has fuelled our rapid ascent through the rankings of one of the most competitive academic autosport events in the world; Formula Student UK at the Silverstone Race Track.

Over the past 3 years, NI technology has empowered several in-vehicle innovations to improved our performance and driver experience. NI technologies were also used for recording data on the track and on the test-bench, to help us intelligently iterate our car designs.

These incremental improvements have driven us from mid table in 2015 to pole position in 2017, beating 100 other universities to win Formula Student at Silverstone, becoming the first UK winners in the competition’s 19-year history.

“The Formula Student event is a fantastic and highly competitive competition. It takes considerable dedication, hard work and skill to win such an event and we could not be more proud of our students for this achievement. We are quite simply blown away” Dr. Mark Eaton, Academic Supervisor, Cardiff University

Media Coverage.

- iMechE: Data, fuel and aerodynamics key to Cardiff Racing's Formula Student success

- Eureka: Cardiff University team becomes first UK Formula Student winner

- ITV: Cardiff Racing’ team make history by picking up Formula Student 2017 title at Silverstone

- The Engineer: Cardiff takes Formula Student crown in first ever UK win

- Race Tech Magazine: Cardiff University team becomes first UK winner of Formula Student

Product Used.

- LabVIEW

- NI myRIO

- Stratom X-CAN Adapter for myRIO

- NI sbRIO 9637

NI for Incremental Performance Improvements.

Cardiff Racing is proud to have been sponsored by NI for the past 3 years. NI sponsorship has granted us access to cutting edge data acquisition and embedded technologies, which have played an increasingly vital role within both our vehicle and our test benches.

Some NI based systems have been installed in-vehicle, boosting both performance and driver experience. As detailed in the later sections of this article, this year we integrated two major innovations into the car:

- Electronic clutch by wire, using a myRIO and a high torque servo

- Custom driver display, using an sbRIO and the Amulet display

Other NI systems have given us access to a world of data and insight, allowing us to better understand the car and make informed decision on how to iterate our designs to boost performance. NI has been used to measure key vehicular attributes, including everything from engine temperatures to wishbone strain to wing deflection. For example;

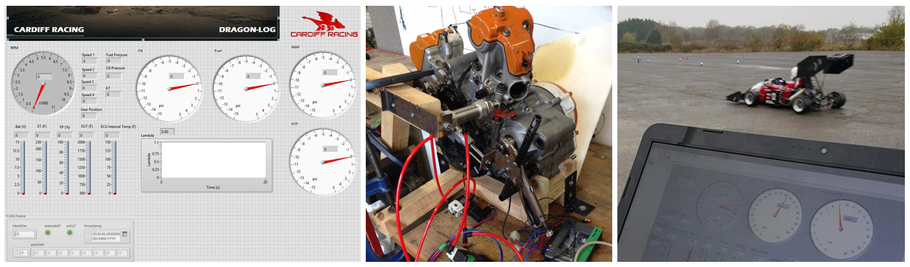

- F1 inspired Wireless Telemetry: Remote access to live data on the racetrack (myRIO)

- Dragon-log: Extracting insight from our ECU and Electronic subsystems (myRIO & Stratom X-CAN)

- Test Bench Verification of Pneumatic shifting system (myRIO)

Aside from performance enhancement, our relationship with NI also led us to visit the company’s Manufacturing Facilities in Debrecen, Hungary. Not only did we receive an informative tour of the cutting-edge facilities, Cardiff Racing was proud to exhibit our car for office staff and we even got to present our designs to the NI management team.

Our Inspiration.

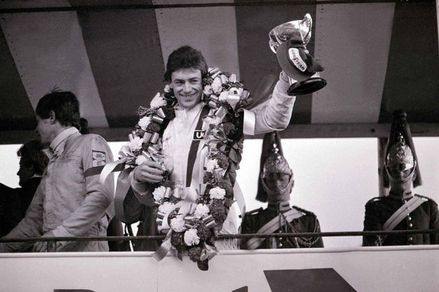

Tom Pryce was Wales' only ever Formula One race winner, having taken the chequered flag at the Brands Hatch Race of Champions in 1975. His promising career was cut short two years later when he was killed during the South African Grand Prix. Tom Pryce had been faster than world champion drivers James Hunt and Niki Lauda in practice sessions in South Africa, but tragically crashed during the race itself.

Tom Pryce was a great inspiration to our team. As such, wanted to race in his memory - by naming the car ‘Gwyneth’, after his mother, and also mimicking his racing colours.

2017 Innovation #1: Electronic Clutch by Wire

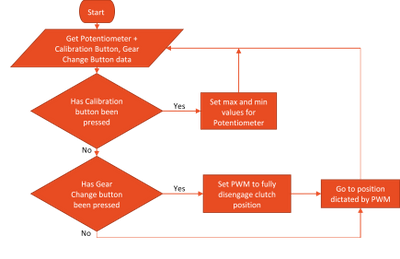

We designed and developed a novel method of actuating a clutch lever on a Formula Student race car. The system uses a position controlled Servo motor to grant the driver full control of the clutch. The mechanism replaced the manual operation of the clutch by the driver, to ensure the fastest possible downshifting and launch acceleration.

The servo motor chosen was the Hitec HS-1100WP due to compatibility with the 12V rail available on the car. In addition, the servo provides a high torque output (8.24Nm) at a speed of 0.26s to get from zero to 60 degrees.

The NI myRIO controller was used to tie all of these components together, executing a LabVIEW real-time application that followed this execution flow:

The Electronic Clutch system works very well. The servo is able to quickly disengage/reengage the clutch of our Triumph engine, enabling swift downshifting and improved acceleration at launch.

The Future of the Electronic Clutch

- Work on automation, adding additional intelligence to enable race-tuned automatic gear shifting

- Because the clutch needs to be one of the most reactive and deterministic systems on the car, we should push more of the code into the myRIO’s built-in FPGA. A resulting reduction in latency will deliver a further performance boost.

2017 Innovation #2: Custom Driver Display

After the successful use of the myRIO for wireless telemetry and datalogging in CR12 (last year’s car), we wanted to extend the capability of the system to add additional inputs, additional sensors and it can interface with the full colour, touch screen HMI from Amulet Technologies.

As such, we decided to port our code from the myRIO to a sbRIO 9637, which provide further processing power, additional inputs and built in support for CAN and RS232 protocols, which were required for commutation to the Amulet display.

It took us very little time to bring our existing code onto the new sbRIO controller. And it was easy to extend the code to interpret CAN messages from the ECU to identify pertinent information (such as current gear, speed, temperatures), before transmiting them with RS232 to visualise the live car data to the driver.

The Results.

Throughout the weekend of Formula Student, our team’s building and engineering skills were put to the test as the car went under serious scrutiny by the judges, before we took the car onto the track to perform several speed and agility tests. Once all the judging was complete late on Sunday night, Cardiff Racing were crowned Class 1 Champions.

Aside from the overall win, Cardiff Racing won 4 additional trophies:

- Sprint Winners (fastest lap of the competition),

- The Bosch Award for Best Braking System

- Exxon Mobil Innovation Award, for the design of our aerodynamic exhaust

- The Jaguar Landrover Virtual Engineering Award

The Virtual Engineering Award, judged by engineers from Jaguar Landrover, looked for innovative use of software for design and technology development. As you can imagine, our LabVIEW based electronic clutch (myRIO) and driver display systems (sbRIO) played a crucial role in securing us the award. With JLR also commending our data driven approach to design iteration.

The next engineering challenge for Cardiff Racing: build a new trophy cabinet

Conclusion.

In total, more than 2,000 students from 24 countries took part in the event. To beat teams from 100 prestigious universities, to be crowned the 2017 champions, goes beyond our wildest dreams. So, we are grateful to NI for helping to drive us into pole position, and making our dreams a reality.

Becoming the first British team to win the competition has allowed us to both create a little piece of history and to create a fitting tribute to Tom Pryce, the Welsh F1 legend who inspired our work.

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Two nice updates for 2017! Congratulations Cardiff Racing! I hope the new systems help you at the forthcoming FS events.

Senior Marketing Engineer, National Instruments

Connect on LinkedIn: https://www.linkedin.com/in/richard-roberts-4176a27b/