- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

How to achieve fast voltage measure with Keithley 2612

Solved!02-25-2019 11:53 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hello, everyone

I'm working on a project about novel semiconductor and now I have achieved a fast photo-detector (response time within 10us). Now I would like to demonstrate my detector by tracking a fast-moving light-spot.

The problem is the LabVIEW project measure speed is only about 100hz. however, by checking the datasheet of Keithley 2612, under 0.001NPLC setup the I/O speed can reach 8000hz. That confused me a lot.

I have searched the forum and someone said by turn off the auto-zero and auto-range can increase the speed. But those methods can't work.

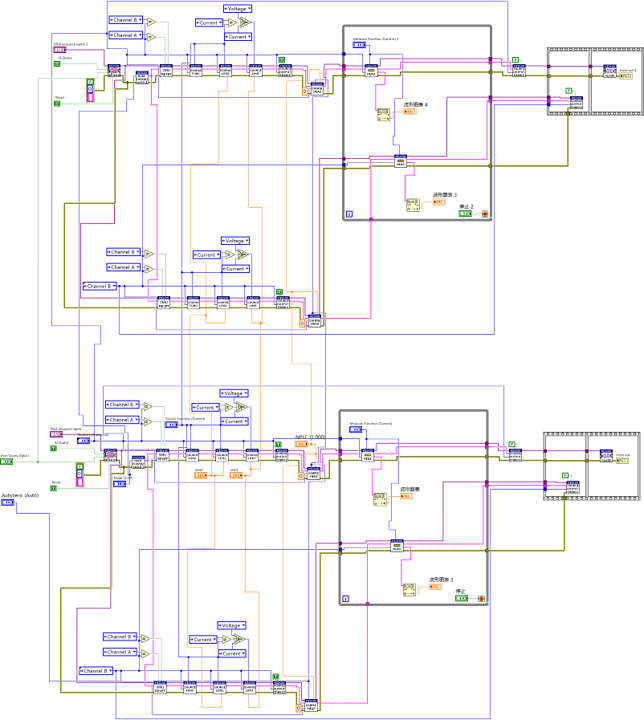

Here is my LabVIEW project, is there any suggestion for me to increase the measurement frequency to about a few kHz?

Best regards!

Solved! Go to Solution.

02-26-2019 07:13 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

02-26-2019 07:43 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

I mean turning off auto-zero and auto-range doesn't significantly increase the measure frequency. I don't know the reason , I am still new to LabVIEW

02-26-2019 07:59 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

02-26-2019 08:19 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

I see.

But I have set 'off' of each measure config sub vi. The speed doesn't increase. Maybe there are other reasons?

02-26-2019 09:30 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Here's what's making your code slow. You are not taking advantage of the K2612s internal memory, but sending read commands to do single measurement for each channel in a FOR. So you have to write to the SMU, then read from it to get a single reading, and you do that twice per loop - once for each channel. You must eliminate multiple unnecessary and slow communications with the PC.

To do that you need to setup internal measurements. You tell the K2612 to take N readings after a trigger, at a fixed time interval, and then return all of that data at once. That is how you get faster measurements. This is not an easy setup if you need to be measuring on all 4 SMU channels at once. Its possible, but a begginer user of SMU and LabVIEW would have a very difficult time programming this!

You are going to need to do a lot of reading the manual to figure out the SMU capabilities and triggering model. You should look to see if there is a pre-written TSP script that does what you need, then learn how to run that. I'm not sure what the fastes K2612 trigger time is, and if its fast enough for you. You would probably be better off with the detector connected a high speed scope.

But you don't really describe your measurement. I'll guess.. You're pulsing or shining a laser onto your detector (which is at a fixed Voltage bias) and measuring the current response? What current level do you expect when laser is hitting detector? What is the dark current level? What are the pulse lengths? Why are you using two k2612s in your code? Are these two Keithley 2612 synchronised using a trigger cable?

Before I can offer more advice about using the K2612 you should describe the measurement, what all channels of both SMUs are doing, and all details of how fast you want to measure.

Craig

02-26-2019 10:06 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Thank you for your advice!

I was thinking to use some kinds of buffer to speed it up.

The reason I chose K2612 is the detector need a calculation circuit to process the tracking position and that circuit especially the amplifier haven't designated yet. The voltage (detector keeping irradiated by a moving light) is measured under zero bias in this demo and the voltage response without amplified can't be clear collected with a scope. The voltage range is e-6 ~ e-2 (V) and this LabVIEW project use the common internet cable and a router to connect PC and two K2612s in one Local network

the

02-27-2019 07:47 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@losking wrote:

The reason I chose K2612 is the detector need a calculation circuit to process the tracking position and that circuit especially the amplifier haven't designated yet. The voltage (detector keeping irradiated by a moving light) is measured under zero bias in this demo and the voltage response without amplified can't be clear collected with a scope. The voltage range is e-6 ~ e-2 (V) and this LabVIEW project use the common internet cable and a router to connect PC and two K2612s in one Local network

It looks like you might have a couple of considerations to make here.

You discuss tracking position. You will need to balance the speed of the K2612 for your feedback calculations versus the size of the buffer needed.

Next, you mention common internet cable and a router. Typically, a test system would be setup with two network cards in the PC. One for normal network traffic and the other for instrumentation access across the LXI connections.

If it helped - KUDOS

If it answers the issue - SOLUTION