Inactive

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

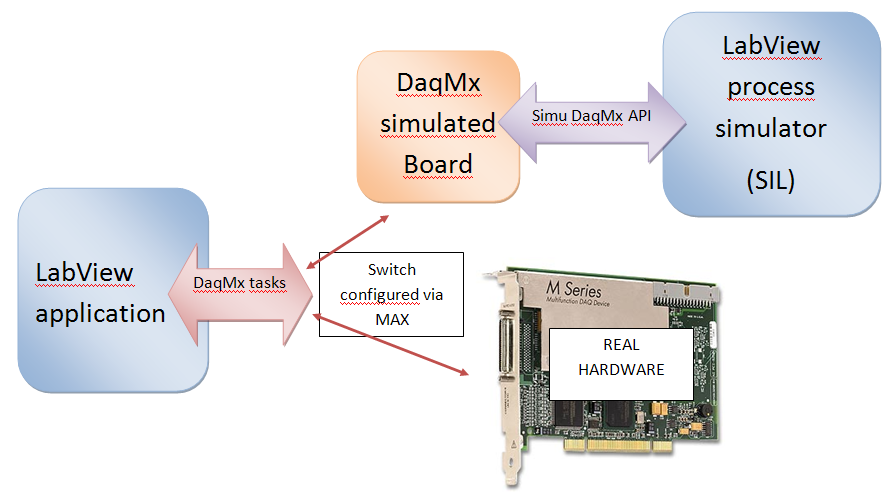

Interactive DaqMx simulation interface ... (Popup panels for simulated hardware) ... Or better, DaqMx Simulation API for process simulation ...

Hello,

How often you have build Labview applications using simulated DaqMx boards ...

And how often you were limited by the default behaviour of simulated boards ... ( Sinewave for analogic inputs, Counter square signal for digital inputs ... )

It would be nice to integrate in DaqMx simulated boards, the abilty to modify the default behaviour of simulated inputs ... thru dedicated popups

It would be nice, for each task linked to a simulated daqMx board, to launch a popup window ...

- For digital input, give the abilty to modify for each configured channel , the current binary value.

- For analog input, give the ability to choose between a fixed value, a sine wave, a square signal ... white noise ...

- For digital output, give the ability to view the current setted values

- For analog output, give the ability to view the current simulated output value on a waveform chart ...

A more powerfull tool could also integrate a simulated channels switching mechanism ... A simulated output could be linked to a simulated input

This feature could be a good way to create an application which could simulate a complete process ... this application could be used to validate a complete system

(such a kind of SIL architecture)

Other idea .... A complete daqMx simulation API ...

- Creation of an API which could instanciate a simulated daqMx board (Wich could be seen via MAX)

- Takes place of the actual limited daqMx simulated board

- This device could then be accessed by other application thru daqMx

- This API could have access to all channels of this simulated device.

- This API could force, programmatically, the value of the simulated input channels according to a realistic process model

Something like this ...

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.