I was thinking for very large systems that use the same channel configuration for multiple channels on the system configuration can be very tedious. A work around for this is the API to build a system definition file but for those customer's with limited or no LabVIEW or .NET experience this isn't valid.

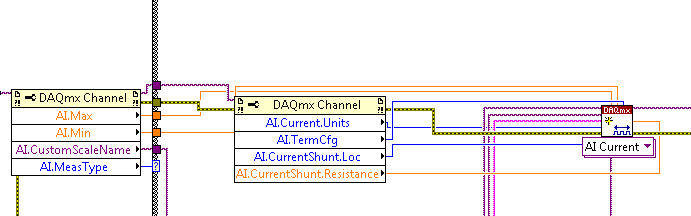

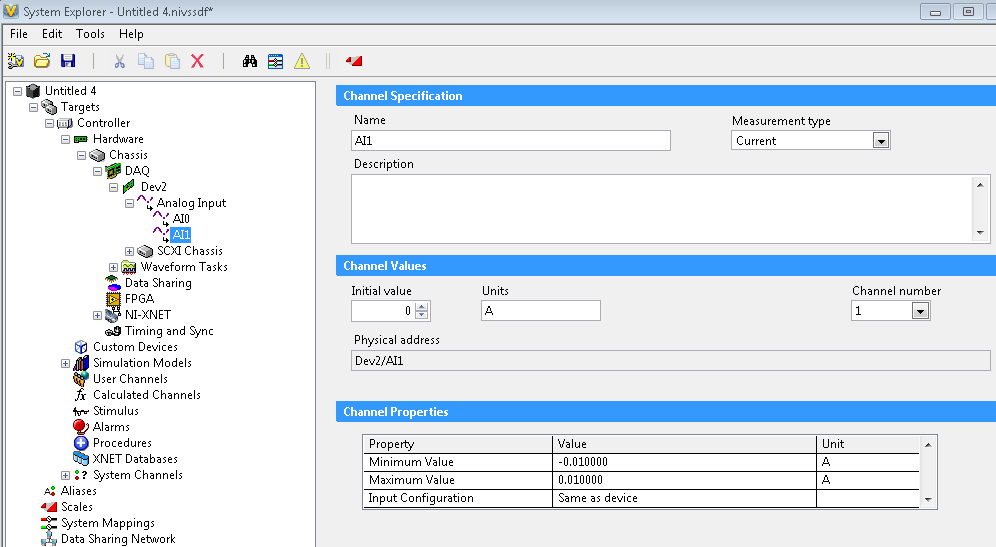

Since we can test the IO channels in MAX by creating tasks for all of our hardware I would like to add the ability to pull the configuration information from a task we've created in MAX and apply them to our channels in VeriStand. So in stead of setting MIN, MAX, input configuration, shunt resistor location and value for 100 channels I can configure it in one location (MAX) and apply the settings to all my Current Channels.

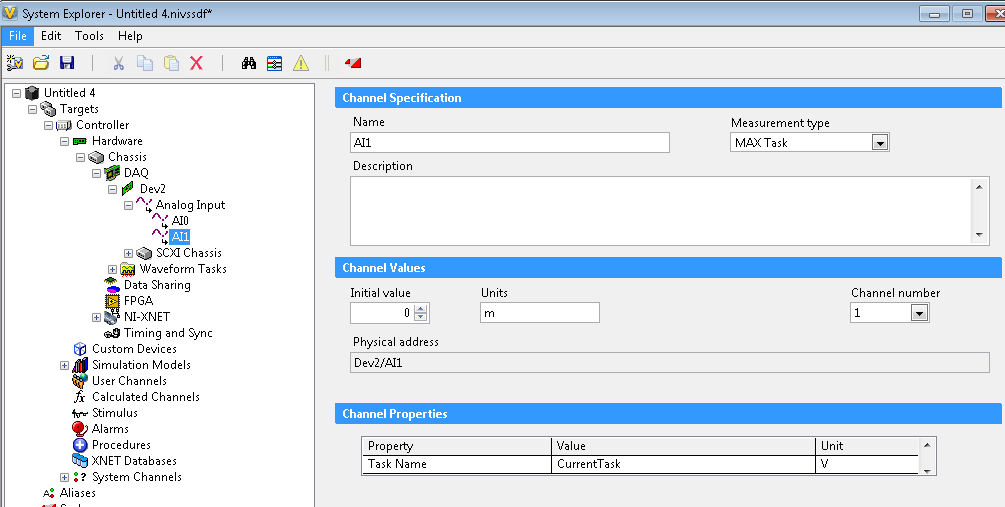

The other issue is if the channel doesn't support all the configurations from each page then we need to contact NI support to add functionality. Recently I worked with a LVDT sensor for a SCXI chassis. This allows customers to have an instant workaround rather than having for NI to allocate resources to update the page.

By adding MAX task to act as the template for our channels we can edit the parameters for all channels of the same setup from one location (MAX) vs each individual page. This also allows you to test individual channels instantly in MAX to make sure the configuration is valid without resolving other errors across the whole system definition.

Again this is more for deployments where they have 100s of channel similarly configured where configurating each channel is tedious but they are not unique.