- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Wiring NI 9219 to collect 4-20mA current

03-12-2014 07:20 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi,

I'm having some trouble getting a NI 9219 to measure current in the lab.

It works fine on my test bench using a simple 9V battery and 470 ohm resistor.

In the lab it's connected to a sensor that's supposed to provide 4-20mA output.

A handheld Fluke meter shows a fairly steady 14mA but the NI 9219 pegs at 25mA which I believe means it latched.

I'm connecting to pins 3 and 5 on the NI 9219.

I suspect there may be some initial current spike when power is supplied to the sensor and the sensor dynamically sets the current.

If so, it seems like a resistor in series with the NI 9219 may be the solution.

Or maybe the NI 9219 needs to be RMA'd.

The manual for the 9219 didn't indicate any need for a resistor in series and the Fluke meter didn't need it.

Any suggestions ?

Thanks!

Dave

03-13-2014 02:30 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hello Dave,

Just to clarify your setup, could you please post a diagram of how you have the sensor, the power supply for the sensor, and NI 9219 wired together? Also, what software are you using to read the measurements from the NI 9219, your own LabVIEW code, example code, or NI MAX (task or test panel?)?

Field Applications & Systems Engineer

National Instruments

03-13-2014 03:17 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi Matthew,

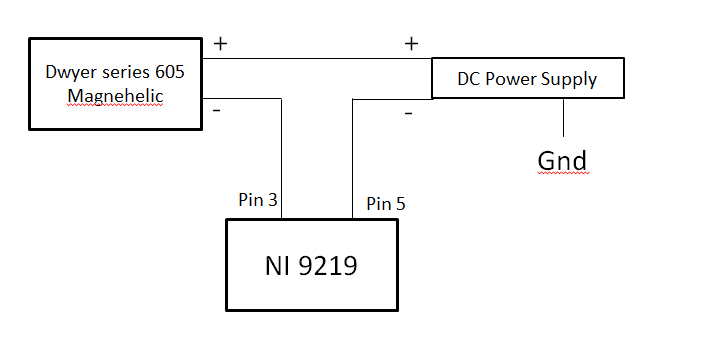

Below is the diagram. Attached is a document for the Dwyer Magnehelic sensor which is providing the current we're attempting to measure.

For the DC power supply we tried both a 24 DC transformer plugged into house power ( 110V AC ) and also a simple 9V battery.

The cable lengths are all fairly short, just 3 or 4 feet with maybe the longest being the + side of the connection between power and the Dwyer

sensor. That line is maybe 10 ft.

For the test using the Fluke hand held current meter we simply swapped it in place of the 9219 using the same connections as shown in the diagram.

The fluke had no problems and showed a fairly stable 14mA coming out of the Magnehelic which is the value we expected.

For the test case we used the NIMax test panel. Later we'll be using custom software but for now it fails using the NIMax software ( test panels )

The 9219 is installed in a cDAQ-9171 and connected to the PC using USB.

It never worked when using channel 0 on the 9219.

When using channel 1 it initially didn't work. But after starting and stopping collection in NIMax a few times, it did eventually start working.

It never worked using channel 0 even though we attempted to reset by starting and stopping collection in NIMax. We also tried unplugging the

USB cable to perform a full reset of the 9219. When I say it didn't work, I mean that the NIMax showed a current of 25mA and appeared to

latch which I interpreted to be an error condition since it continued to show 25 mA even when the signal lines were removed.

On my test bench, I just used a resistor in place of the magnehelic and a 9V battery in place of the DC power supply.

Channel 0 works great in that configuration. It's just somehow not happy with the Magnehelic even though the Fluke is fine with it.

Thanks!

Dave

03-13-2014 03:20 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi Matthew,

One further point to clarify.

When channel 1 worked, that test was done using a 9V DC battery as the power supply.

We didn't attempt that test with the 24V power supply.

Thanks

Dave

03-14-2014 01:06 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Dave,

It does look like you have the wiring configured correctly.

Just to be clear, channel 1 reads the current (the same as the Fluke hand held), but channel 0 does not (rails out to the full 25mA)?

Are you able to measure resistance with your Fluke hand held, or do you have a DMM lying around, which you can use? I’d like you to check the resistance of channel 0 verses channel 1, essentially this is the effective shut resistance is which the device is using to measure the current, they should be the same. First, disconnect the wires from terminals 3 and 5, so that the circuit is open. Then run the test panel in NI MAX, as you have before. What does it measure the current as for an open circuit? Then connect you DMM to pins 3 and 5, and measure what the resistance is. Do this for both channels 0 and 1. This will tell us if channel 0 is faulty.

Field Applications & Systems Engineer

National Instruments

03-16-2014 10:33 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi Matthew,

1. Just to be clear, channel 1 reads the current (the same as the Fluke hand held), but channel 0 does not (rails out to the full 25mA)?

- Yes, in the lab connected to the Magnehelic channel 1 worked ( after hitting the rail at 25mA for about 30 seconds it was eventually able to work after starting and stopping NIMax a few times ). It never worked for channel 0 even after starting and stopping NIMax a few times.

- The Fluke handheld meter always worked when reading the Magnehelic current .

- At my test bench using just a resistor and battery in the circuit, both channel 0 and channel 1 always work and give values that I expect. That's why I suspect it's an interaction between the Magnehelic sensor and the 9219 device.

2. What does it measure the current as for an open circuit?

- both channel 0 and channel 1 show effectively 0 current for open circuit ( around 150 E-9 )

3. Then connect you DMM to pins 3 and 5, and measure what the resistance is

- I performed this test using a different DMM that's lower quality than the Fluke so the values aren't super accurate

- channel 0 resistance is 29.6 ohms AFTER performing the NIMax open circuit test above and exiting NIMax

- channel 0 resistance is effectively infinite when the 9219 is not plugged into power (usb)

- channel 0 resistance is effectively infinite after plugging the 9219 into power but before running NIMax

- channel 1 resistance is 29.6 ohms AFTER performing the NIMax open circuit test above and exiting NIMax

- channel 1 resistance is effectively infinite when the 9219 is not plugged into power (usb)

-channel 1 resistance is effectively infinite after plugging the 9219 into power but before running NIMax

- Note that for both channel 0 and channel 1 the resistance depends on history.

- If I sample current on channel 0 then exit NIMax, the resistance of channel 0 is 29.6 ohms and channel 1 is infinite.

- If I sample current on channel 1 then exit NIMax, the resistance of channel 1 is 29.6 ohms and channel 0 is infinite.

Thanks

Dave

03-17-2014 01:24 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hello Dave,

- I agree with your suspicion about this issue being related to the interaction between the Magnehelic sensor and the 9219 device.

- I wanted to know what the NI MAX test panel read to you, if you had nothing connected to it. It should be 0, as you have observed. Thank you for that information.

- The reason that it depends on history, is because the module is engaging the shut resistor for measuring the current, but does not do this unless you have configured the device to do so. It does not have the shut resistor engaged all of the time, as the device does more than just measuring current from those pins. The device configures its circuitry for the type of measurement you set it to take. The fact that the resistances of both channel 0 and channel 1 are the same, leads me to believe that channel 0 is not faulty. However, that doesn’t meant the device is still not at fault, it may be that the internal circuitry for measuring current, up to the shunts is fine, but the circuitry afterwards, maybe up to the actual ADC even, may be the problem.

What I would like you to do is, instead of measuring current with these channels, let’s try doing a voltage measurement, and convert it into current afterwards using Ohm’s law. This will allow us to troubleshoot the cause of this issue and see if it is related to the current measuring circuitry internal to the device.

Connect the NI 9219 in parallel with a small resistance resistor; see Figure B in the document for the Dwyer Magnehelic sensor you linked me to in your earlier post (make sure to change the input pins of the NI 9219 to be pins 4+ and 5- for voltage). First try a resistor of 30 Ohms; to emulate the NI 9219’s shunt resistance. Then try 700 Ohms, which is what the document suggests in Figure C for a supplied power of 24V. Does reading the voltage/resistance yield the correct current measurement you are getting from the Fluke hand held (14mA)?

Field Applications & Systems Engineer

National Instruments

03-17-2014 05:24 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi Matthew,

I can arrange to do this test but it might take a few days. The lab is in another location and I need to schedule time on the equipment to run the test.

If I understand you correctly, I believe the tests are to determine if the voltage output from the Magnehelic is compatible with the 30 ohm resistance in the NI device. For a current of 14mA and a resistance of 30 ohms, that would require the Magnehelic to output 30 x 0.014 = 0.42Volts. It sounds like the test you're suggesting is to confirm that the Magnehelic is operating correctly in that voltage / current / resistance range.

If the Magnehelic doesn't operate properly with 30 ohms but does with 700 ohms, then I'm guessing the suggestion would be to put a 670 ( or thereabouts ) resistor in series with the 9219. Is that a special part offered by National Instruments as an option for the 9219 or is it something I should cobble together elsewhere ? It would need it to be in an industrial style enclosure with clean wiring.

Are there other follow on tests I should do at the equipment based on the results of the tests you suggested ?

I'd like to minimize the number of times I need to schedule equipment time.

Thanks!

Dave

03-18-2014 04:12 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hello Dave,

The test should also determine if the Magnehelic is working correctly yes, but the purpose of this test is more to figure out if the current measuring portion of NI 9219’s circuitry is faulty. If it is faulty, then you should consider sending it to National Instruments as a Return Material Authorization (RMA) request to get it fixed.

I expect that the Magnehelic will not operate as it should with the 30 ohms, but would with 700 ohms, since the documentation for the Magnegelic says to use 700 ohms for voltage measurements, not 30. However, the actual reading is not what we care about; we just want to know if the NI 9219 is reading the same voltage, for either resistance, as the Fluke device.

If you are looking for another test to run while you have the equipment available, I suggest you also try an internal connection test. Open up the Voltage – Continuous Input.vi example (Help>>Find Examples> Hardware Input and Output> DAQmx>Analog input) shipping example. Then right click the Physical Channels control, select I/O Name Filtering, and check off Internal Channels. You should now be able to click the drop down for Physical Channels and select “9205/_aignd_vs_aignd”. Run the VI and see what you get for voltage reading.

Field Applications & Systems Engineer

National Instruments

03-08-2017 02:50 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

In case someone else stumbles into this post; simply put a 250 Ohm resistor in the current loop and the NI 9212 will then have the correct current to read properly.