- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

cross corelation

01-27-2016 10:20 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hello everyone!

In my application, I am acquiring current waveform of a DC motor. My hardware consist of a current to voltage converter which then I am giving it to my NI USB6009 card. I am acquiring 40k samples at rate of 10k.

These waveform are then stored in excel file.

I am currently comparing the acquired data with a previoulsy stored master file(vi attached). The nature of waveform is usually similar to a sinusoid.

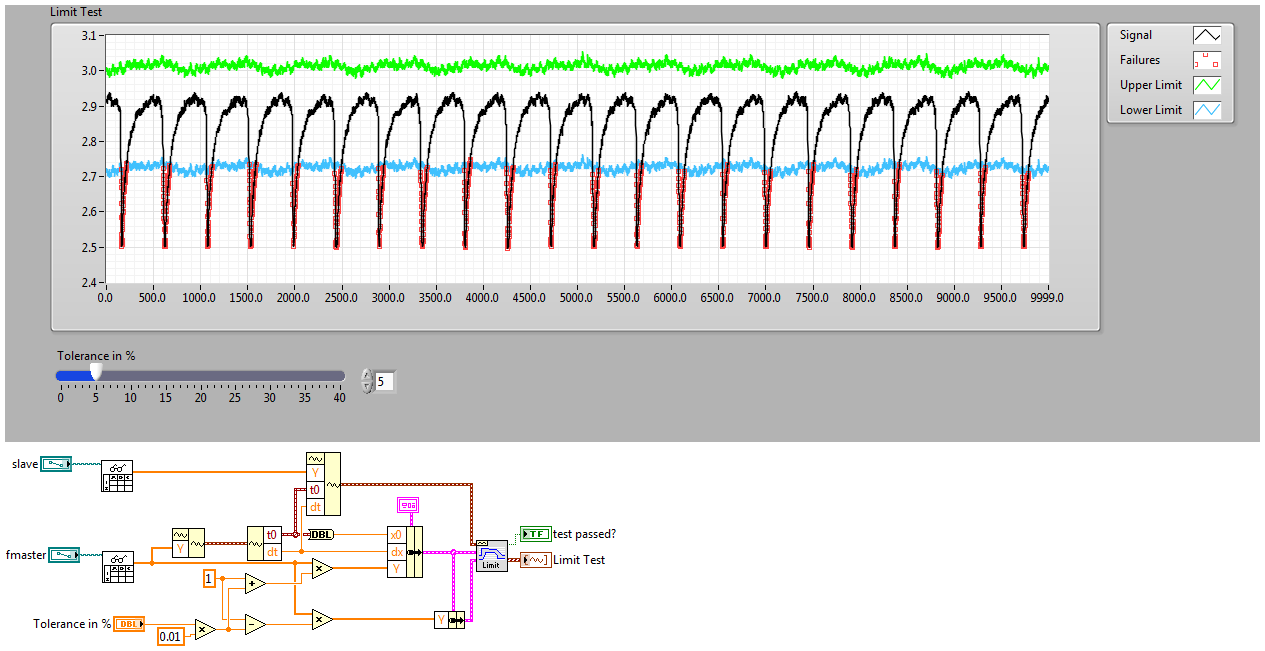

In my vi I time shift the waveform and compare it with the master. If each datapoint is within the set tolenace range, the waveform is treated as ok.

But my problem is, even if there is a fault in my motor(which can be visibly identified by the nature of waveform), but since all the data points are inside the set limits, it still says it as OK.

So I thought of using cross-corelation to determine the nature of waveform. But I am not able to do it sucessfully.

Currently for testing purpose I have both in my code.

I am attaching the vi as well as some sample waveform files.

Note: HOOK MISS, WIRE CUT are the manufacturing faults which. Faulty waveforms should be identified. The nature of fault is not important.

Can someone please help?

01-28-2016 04:39 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Use Waveform Monitoring VIs >> Limit Testing VI http://zone.ni.com/reference/en-XX/help/371361K-01/lvwave/limit_testing/

Take a look at the example that ships with LabVIEW:

- Limit Testing Measurement VI: labview\examples\Signal Processing\Waveform Measurements

01-28-2016 04:48 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Thank you for replying aCe.

I will surely try this out. It is similar to what I was trying to do before by calculating +- of set tolerance in percentage of the master and seeing if all the data points are in that range.

This works fine for some.

Problem happens when some of the ok waveforms(sinusoid in nature) have a little bit different offset and hence they go out of limits. and vice versa some show problems visibly(waveforms are not sinusoid in nature), but the variance is not much.. in a few milivolts. so just because their every data point is within tolerance, they are passed.

For more understanding, you can try out the 'ttr' files from the attachement.

I will surely try your suggested technique and reply.

Thanks once again..

Rohan

01-28-2016 05:39 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi aCe,

I implemented your code.

It does not seem to work for some cases. For example in case of ttl.

I can see the waveform is not sinusoid in nature like the master(ok) one but still since all the points are in limits, it gives as test passes.

Is there any other way?

Any help from anyone would be appreciated.

Thanks and regards,

Rohan

01-28-2016 06:32 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hello Rohan,

You are trying to correct your measurement anomalies in software, you would have better success if you measure your signals correctly to start with. I am not sure the stimulus used in your test, explore the possibility of using one of the signals to trigger your data acquisition.

Some information on triggering here:

http://www.ni.com/tutorial/4329/en/

What parameters were considered in chosing the % limt?

01-28-2016 06:39 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi aCe,

This system will be used on an assembly line for DC motors .

The master is recorded earlier by enabling a dc source through my labview program.

I take 10k samples using my NI USB6001. The waveform we see is a current waveform, which is converted to voltage using an hall effect sensor.

I can control when supply is given to the motor, but value of starting sample will always be different.

01-30-2016 12:10 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Could anyone solve it?