- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Order analysis - speed profile from measured data in Hz

Solved!11-22-2012 03:07 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi,

When I want to perform order analysis in LV I need to have tacho signal. I understand it that I need some "TTL" signal where is one pulse per revolution. ____|-|_______|-|___|-|_______ The period depends on the rotating speed. This signal is transformed in LV to even-angle signal and output is speed profile signal which go to OA blok.

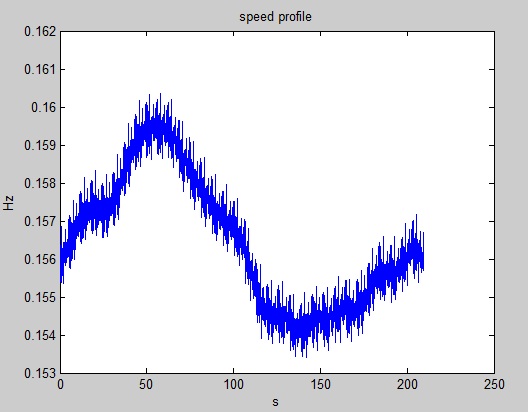

However I my case I do not have TTL signal from tacho but rotating speed signal in Hz and coresponding time values.

I know that rotating speed is about 0.1 - 0.2 Hz. I have 200 secunds of signal with 4000 samples of rot. speed in Hz and coresponding time values. I want to do the speed profile cluster which contains time array and RPM array. My idea is just take the time values and rot. speed in Hz multiplied by 60 to get RPM.

However I am not sure about this. The results from OA seems to me not to be correct. Does some do something like this ?

Solved! Go to Solution.

11-23-2012 09:31 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi Charlie,

Even the frequency f in Hertz seems to has the same unit [1/s] as the angular speed (omega) [rad/s] or just [1/s] , remember the relation:

omega=2*Pi*f,

and the relation between angular speed and RPMs

RPM=omega*60/(2*PI)

so, as you stated in your post, RPM = f * 60, this should be correct.

What do you mean, that the analysis doesn't seem to be correct? I'm not really sure what's the problem about. What is the target of analysis?

Thanks for explaining. Have a nice day

NIEE Aplications Engineer

11-23-2012 09:57 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Thank you for your post.

Often, we are limited to speed measurements produced by the control system. In this case, for order anlysis to work, we must simulate a tachometer/encoder signal that best represents the speed of the machine. The Order analysis routines expect a tachometer signal to have at least one "pulse" per revolution.

I do not have the code handy, yet have developed a continious pulse generation function which outputs a square wave with say 20% duty cycle, and produces the waveform in block sizes equal to the sample duration of the control system. In this way, we can create a simulated tach pulse waveform which the order analysis tools can use.

Hope this idea helps.

Solutions Manager, Industrial IoT: Condition Monitoring and Predictive Analytics

cbt

512 431 2371

preston.johnson@cbtechinc

11-24-2012 09:00 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

I did a small research with the example VI from S&V library and also I found in NI page that "speed profile specifies the arrival time and the rotational speed of each tachometer pulse". I understand that every pulse (e.g. one per revolution) I get one speed value in RPM. However my signal have definitely more then one pulse (sample) per revolution. I suppose acc. to this page that an encoder is used because the rotation speed is very slow. The point is that I do not know nothing about the encoder ( how many pulses per rev) and how to transform the signal to be correct for speed profile or whether does any VI exist to use this kind of speed signal to produce order analysis.

11-24-2012 11:55 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Try the attached VI. It takes two arrays of equal size, the speed in RPM and the timestamp from the control system. It produces a continious time waveform which can be used with analog tach VI from the order analysis tools.

Solutions Manager, Industrial IoT: Condition Monitoring and Predictive Analytics

cbt

512 431 2371

preston.johnson@cbtechinc

11-25-2012 05:48 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Thanks. I would like to try it but I am not sure what does the variable TW sampling rate mean. Can you explain please.

11-25-2012 07:17 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Thanks for the reply, The TW Sampling rate, is the sample rate you are sampling the vibration signal at.

Solutions Manager, Industrial IoT: Condition Monitoring and Predictive Analytics

cbt

512 431 2371

preston.johnson@cbtechinc

12-21-2012 02:20 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi again,

my situation has changed a little bit. I want to ask about the VI which transform the speed data to tacho signal one pulse per revolution. Is it possible to modify it to get e.g. 120 sample per rev ?

01-02-2013 03:28 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

If you choose to specify you want a tachometer signal at 120 times running speed, you will get 120 pulses per revolution. Should simply be a parameter change to the VI.

Solutions Manager, Industrial IoT: Condition Monitoring and Predictive Analytics

cbt

512 431 2371

preston.johnson@cbtechinc

09-24-2013 12:16 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi!

Can anybody tell me how to get "timestamp array from the control system" (with example)?