- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

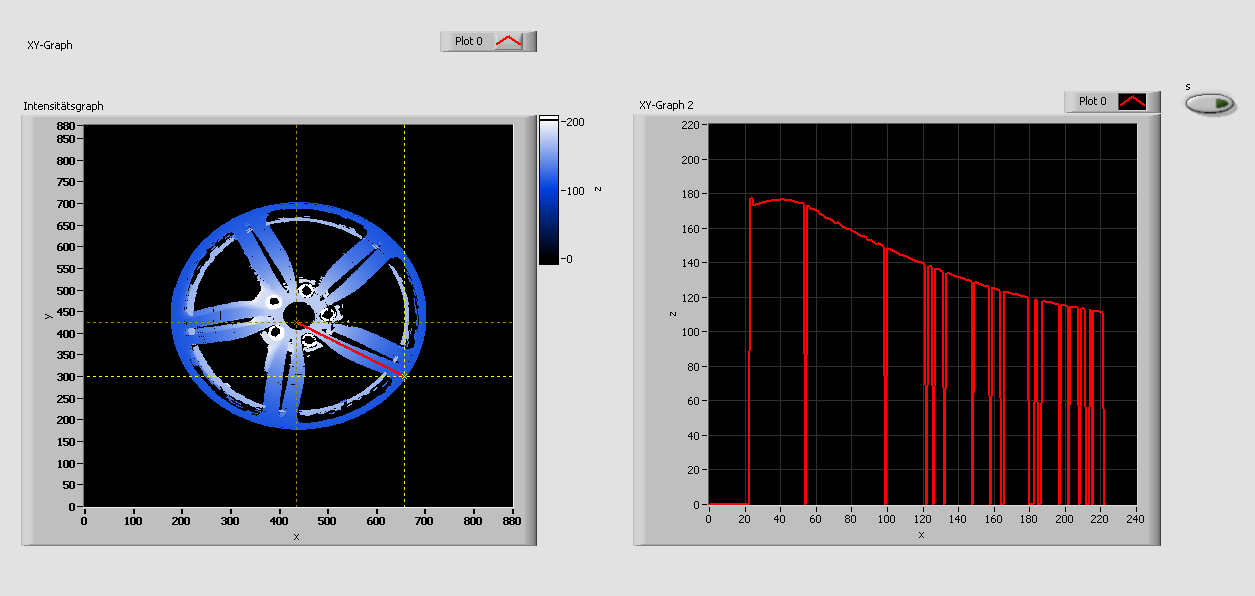

Extracting toolpath profile from 3D scan of wheel

04-08-2014 08:19 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

I'm wondering if anyone here can suggest suitable math steps to extract a 'surface to cut' profile radial line from the test data in the Dropbox folder?

Attached is the vi for viewing the scanned data.

The extracted profile needs to be a radial line that runs across the highest points (the spokes) from the middle of the wheel to the outside edge (standard lathe machine tool trajectory).

There needs to be some level of outlier correction on the data as there is a few erroneous points here and there (obvious in attached 3D viewer).

Scan data and corresponding pictures for various wheels can be viewed here:

https://www.dropbox.com/sh/r9cdmyy5s6iyi6l/0Pomg0dmyp

PS. In the data, +ve Z is downward.

Regards

Marek

04-08-2014 08:51 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Update to avoid out of memory error.

04-09-2014 05:05 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

@marekm wrote:

I'm wondering if anyone here can suggest suitable math steps to extract a 'surface to cut' profile radial line from the test data in the Dropbox folder?

Attached is the vi for viewing the scanned data.

The extracted profile needs to be a radial line that runs across the highest points (the spokes) from the middle of the wheel to the outside edge (standard lathe machine tool trajectory).

There needs to be some level of outlier correction on the data as there is a few erroneous points here and there (obvious in attached 3D viewer).

Scan data and corresponding pictures for various wheels can be viewed here:

https://www.dropbox.com/sh/r9cdmyy5s6iyi6l/0Pomg0dmyp

PS. In the data, +ve Z is downward.

Regards

Marek

Hi Marek,

first a general hint, as your data is a binary file you should zip your files.

Wheel1.bin is about 100 MB large, but if you zip it, you'll get a compact 13 MB file.

The extracted profile needs to be a radial line that runs across the highest points (the spokes) from the middle of the wheel to the outside edge (standard lathe machine tool trajectory).

Do you expect something like this:

1# Define the center of your object A

2# then define a point B on the objects edge

3# Extract tall xyz points which lay on the line AB ?

Regards,

Alex

04-09-2014 07:12 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi Alex, thanks for your reply.

Compressed as recommended!

"Do you expect something like this:

1# Define the center of your object A

2# then define a point B on the objects edge

3# Extract tall xyz points which lay on the line AB ?"

Yes and no. This is a machining process that just skims the top face of the wheel so we are only interested in the highest of points throughout each radial length (I mean we aren't interested in any data down the sides of the spokes or in between the spokes).

The problem is, there are a scattering of spurious measurements that are usually not attached to the main mass (I'm thinking 3D blob processing) to remove before that (radial ring max hold) calculated line can be reliably extracted.

Any ideas?!

04-10-2014 11:34 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

hi marek,

Here's what I had in mind:

1# Extract all the red line's points, use XY Graph to display extracted line

2# Leave those points out which have no hight information (z<0), use XY Graph to display extracted line

I will be away for 3 days, but I'm looking forward to discuss with you

Regards,

Alex

07-29-2014 05:08 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

as requested, here's the code attached